Color Coated Galvanized Steel Coils PPGI

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Surface Treatment:Coated

Technique:Galvanized

Standard:JIS

Application:Container Plate

Edge:Mill

Stock:Stock

Steel Grade:CGCC, Dx51d, SGCC

Color:Ral 1015, 5002, 6005, 8017, 9002, 9006, 9010 etc.

Thickness:0.16-1.0mm

Width:914/1000/1200/1219/1220/1250mm

Base Metal:Galvanized or Galvalume Steel

Zinc-Coating:Z50-150G/M2 or Az40-100G/M2

ID Coil:508mm

Coil Weight:3-5 Mt

Painting:20-25miu on Top / 5-8miu on Back

Type of Coating:PE Smp PVDF

Export Markets:North America, South America, Southeast Asia, Eastern Asia

Additional Info.

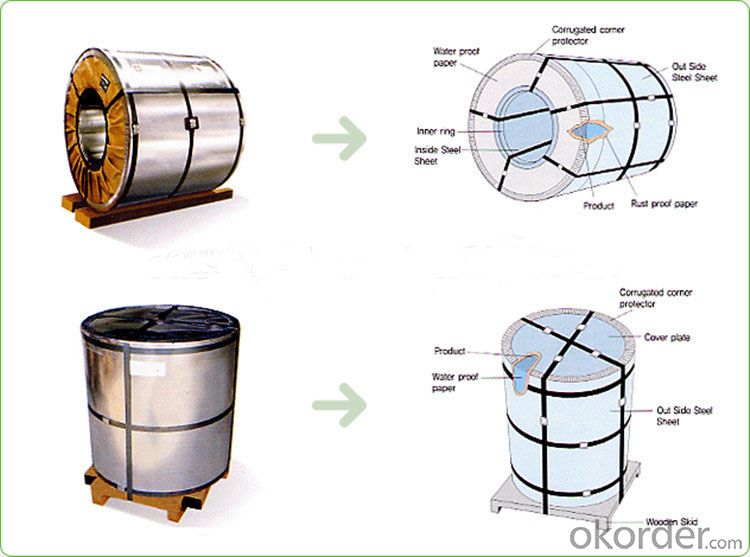

Packing:Standard Export Seaworthy Packing In20′′ Container

Standard:0.14-1.0*914-1250*C

Origin:China

HS Code:72107010

Production Capacity:100000tons Per Year

Product Description

Color-coated Galvanized/Galvalume Steel Coil (PPGI/PPGL)

1. Techinical standard: EN10169

2. Grade: TDX51D, TSGCC

3. Color: Ral standard or according to customers' requirment

4. Thickness: 0.14-1.0mm (0.16-0.8mm is the most advantage thickness)

5. Width: 600-1250mm (610/724/820/914/1000/1200/1219/1220/1250mm)

6. Base metal: Galvanized / galvalume steel

7. Finish Painting: 15-20miu PE on top 5-8miu EP on back

8. Color: Ral standard

Acceptable payment term and way?

T/T,L/C, T/T + L/C, D/P

Acceptable price term

FOB CNF CIF DDU CPT

Do you accept OA payment terms?

Yes, sure, but it normally depending on the order value

Do you have QC team?

Yeah, sure, our QC team is very important, they will keep the qualitycontrol for our products.

What is the validity of your quotation?

Normally 7 days.

What is your advantage?

24 hour quick response /Customer oriented/ Credit foremost/ Top quality Excellent

What is your acceptable payment term?

TT,LC,OA etc

- Q: Molton is formed at 2800 F. Thats a fact. Now jet fuel at its hottest is 1800. Where does the other 1000 degress come in? And it was found at the WTC 7 site. Was this hit by a plane? A simple fire COULD NOT produce molton. This is a fact. Molton is formed during controlled demoliton of a building since all the bombs in the buiding go off and its very very hot. The fact there was MOLTON at the site is shocking to some since it is IMPOSSIBLE for molton to form from jet feul alone. Impossible. It needed another source. Now the claim that I'll get is that it weakened the stell but then we would find weak steel not molton. Why do you seem to throw this off of your shoulder? Do you not want to belive it? I'm no jet fuel guy but I know you cannot make molton by using just jet fuel. This is really proof that 9/11 was an inside job.

- People who believed the buildings collapsed because of the planes are far far off. 1. Burning jet fuel CANNOT melt steel - FACT! 2. The twin towers were built to withstand a hit from a Boeing 707 - FACT 3. NORAD didn't respond - for the first time EVER! - FACT! 4. The pentagon has the most CCTV cameras than any other buildings in the world and they only release the tape which the plane is not visible, they also confiscated the tape from the store opposite which would have shown the plane - if it existed. State sponsored terrorism has been around for along tI'me, im surprised at how many people still believe the official story.

- Q: How are steel coils used in the production of electrical appliances?

- Steel coils are used in the production of electrical appliances as the core material for transformers and motors. The coils are wound around an iron core to create electromagnetic fields that enable efficient energy transfer and power generation within these appliances.

- Q: What are the environmental considerations of using steel coils?

- There are several environmental considerations associated with using steel coils. Firstly, the production of steel coils requires a significant amount of energy and raw materials, which can contribute to greenhouse gas emissions and environmental degradation. Additionally, the extraction and processing of iron ore for steel production can have negative impacts on land, water, and air quality. Moreover, the transportation of steel coils, especially over long distances, can result in emissions from vehicles and contribute to pollution. Lastly, the disposal of steel coils at the end of their lifecycle poses challenges as they can be difficult to recycle and may end up in landfills, further contributing to waste accumulation. Overall, the environmental implications of using steel coils highlight the need for sustainable practices in their production, transportation, and disposal.

- Q: What are the main characteristics of steel coils?

- The main characteristics of steel coils include their high strength and durability, ability to withstand extreme temperatures, excellent corrosion resistance, and superior formability. Steel coils are also known for their consistent and uniform thickness, smooth surface finish, and wide range of available sizes and grades. Additionally, they are easy to transport and process, making them highly versatile for various industrial applications.

- Q: Will a 1 inch thick A36 steel target withstand a 7.62x54r round?

- it depends on the type of steel. If it's soft steel it may stop the round, but leave a craterthat can causeirregular ricochets. If it's hardened steel (AR500 for example), the bullet will just 'splash' and fragment into little bits. It's better to shoot thin steel so the round goes through than shoot thick soft steel thatforms a crater. No matter what type you're shooting, put it no closer than 100 yards for a full power jacketed round. Try to hang the plateso it is angledslightly towards the ground so anymajor ricochets are directed into the ground and not up or back towards you.

- Q: How are steel coils used in the production of rail tracks?

- Steel coils are used in the production of rail tracks as they are processed and shaped into rails. These coils are transformed into long, straight sections of steel that form the main structure of the track. This process involves cutting, bending, and welding the coils to create the desired rail shape and dimensions. The resulting rails are then installed on rail beds to provide a durable and reliable foundation for trains to run on.

- Q: Is there any other way of testing whether or not you have a 1944 Steel penny that won't damage the penny. The magnet test doesn't seem to work cause even when I try to get a 2007 penny to stick to the magnet...it won't. So is there some kind of magnet needed? Like power wise or anything like that, if not then I need to know what are other ways of testing the 1944 penny.

- Weigh it. I'm not an expert on coins, but if the 1944 was 100% steel, I would expect it to weigh something different then modern pennies. Another test would be to measure the resistance with a micro-ohm meter. This is a specialized device that can measure resistance to a millionth of an ohm. Steel should have a different resistance than the metals used on other pennies. Here are some comments from wikipedia: In 1943, at the peak of World War II, cents of zinc-coated steel were made for a short time due to war demands for copper. A few (the U.S. Mint reports forty) copper cents from 1943 were produced from the 1942 planchets remaining in the bins. Similarly, some 1944 steel cents have been reported. Following 1943, salvaged ammunition shells made their way into the minting process, and it was not uncommon to see coins featuring streaks of brass or having a considerably darker finish than other issues.

- Q: How are steel coils used in the manufacturing of defense equipment?

- Steel coils are used in the manufacturing of defense equipment as they provide strength, durability, and resistance to impact and stress. These coils are typically used to fabricate various components, such as armor plates, vehicle frames, and missile bodies, which are crucial for the protection and functionality of defense equipment.

- Q: How are steel coils used in the production of fencing materials?

- Steel coils are used in the production of fencing materials as they serve as the raw material for manufacturing various types of fencing products, such as chain-link fences, barbed wires, and welded wire meshes. The steel coils are unwound and processed through different manufacturing processes, including cutting, shaping, and welding, to create the desired fencing products. The strength and durability of steel make it an ideal material for fencing, providing security and protection in various applications, such as residential, commercial, and industrial settings.

- Q: steel welding with ms steel iron

- Welding austenitic stainless steels to carbon and low alloy steels are established methods in the process and construction industries. Dissimilar metal welds involving stainless steels can be done using most full fusion weld methods, including TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas). Weld procedures using filler (consumable) enable better control of joint corrosion resistance and mechanical properties. In selecting the weld filler, the joint is considered as being stainless, rather than the carbon steel. Over-alloyed fillers are used to avoid dilution of the alloying elements in the fusion zone of the parent stainless steel.

Send your message to us

Color Coated Galvanized Steel Coils PPGI

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords