Wholesale Anodized Aluminum Profiles for Construction Application in Cars

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

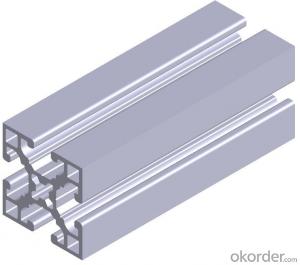

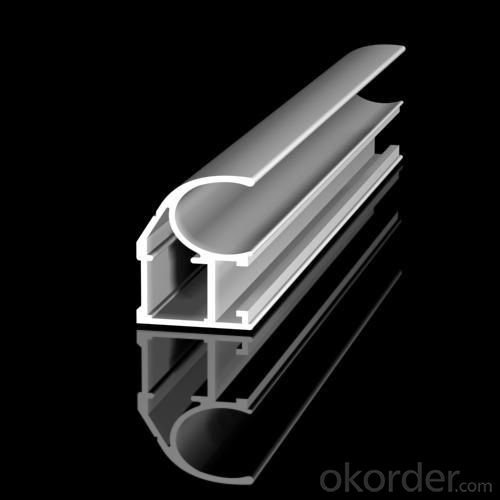

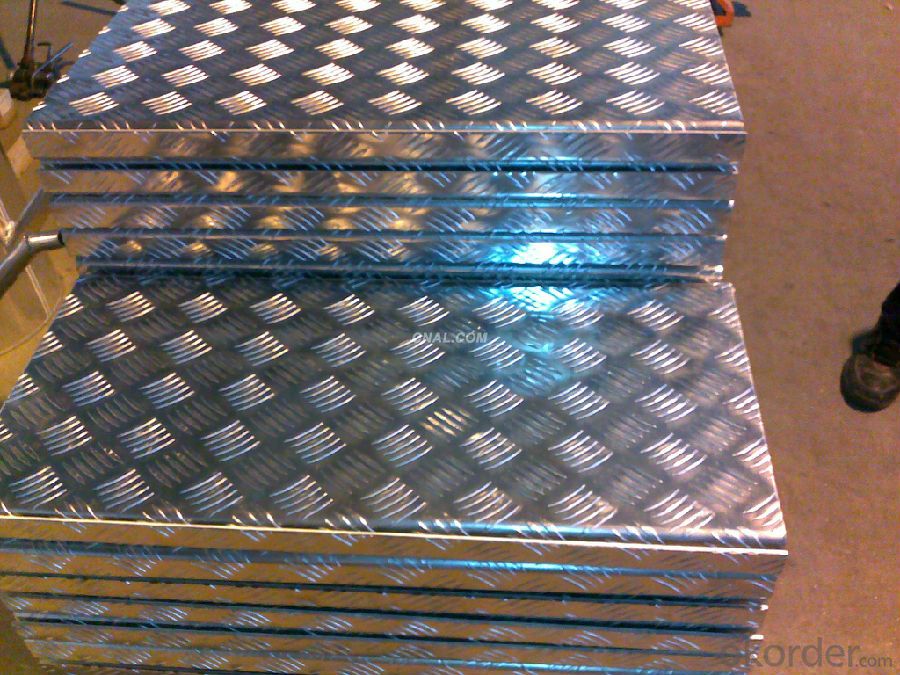

Structure of Aluminium Plate for Construction Application in Cars Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of theAluminium Plate for Construction Application in Cars:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

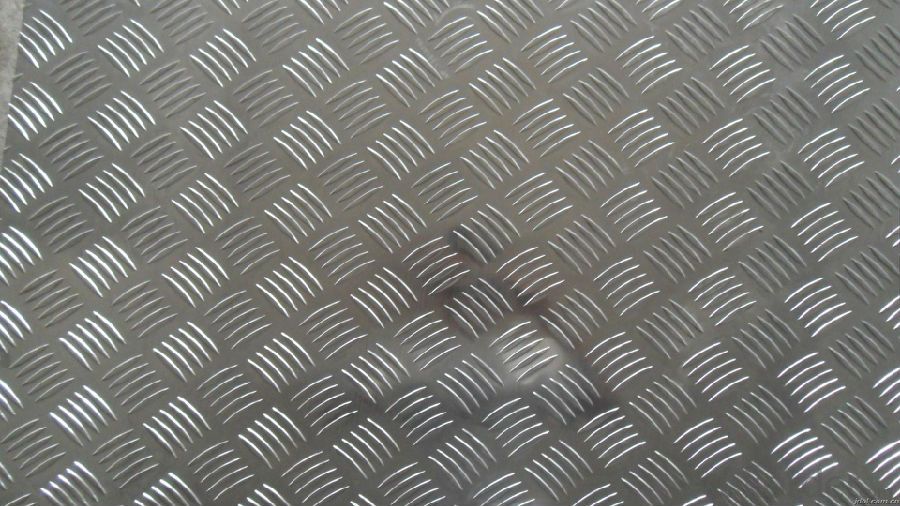

Images of the Aluminium Plate for Construction Application in Cars:

Aluminium Plate for Construction Application in Cars Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: Can someone give me a direction? Thank you

- First of all, the country's biggest industrial enterprise profile Liaoning Zhongwang Liaoyuan Midas Shandong Shandong Hunan Guangxi South Nanshan jungle Sheng Tong Guangdong Luxe Guangdong and the United States they have or will soon be launched high-speed EMU industrial aluminum productsSecondly, the radiator done the best Guangxi south south aluminum, but the radiator specification too, radiator section do few enterprises, the majority of enterprises in the decentralized radiator, small cross section, you have to search.The best solar energy company is Jiangsu's Hyde aluminum, energy aluminum enterprises concentrated in Jiangsu and Zhejiang, it is recommended search.Mechanical equipment is divided into manufacturing machinery and medical equipment manufacturing machinery, aluminum is not much, much maintenance need new materials will purchase, medical devices are mostly aluminum fittings and seamless pipe, little section, which can satisfy the production enterprises can do.Transport can be divided into passenger cars and commercial vehicles in two categories, now on the domestic market of aluminum on the vehicle in popularity is also very slow, promotion is difficult, this is not a salesman to project, to promote the use of a wide range of industry to the understanding, or executive strategy, and promote the country policy......The one or two sentence that is not clear, industry market is still relatively confused, capacity is already saturated, according to the perspective of industrial development, 120% saturated, is conducive to healthy competition, eliminating inferior enterprises, promote the development of technology, but has been more than 150% saturated capacity in China, most are small extrusion machine for the production of building, 70% how to develop materials, industry, still have to see your company's positioning and strategic development.

- Q: Fenglv aluminum material how ah? What aluminum materials do you use for windows and doors?

- Domestic aluminum quality is about the same, mainly you installed in the window accessories, is the key to the life of the service, recommend several brands Bar Reid Jan Ron Lixin spring is not recommended, quality is not very rely on live

- Q: What are the different colors and finishes available for aluminum profiles?

- There are various colors and finishes available for aluminum profiles, including but not limited to natural (mill finish), anodized, powder-coated, and wood-grain finishes. These finishes can be applied in a wide range of colors, allowing for customization and versatility in design.

- Q: Xi'an XAC aluminum sales site.

- For the choice of aluminum profiles, here are a few suggestions for you to refer to:First: very cheap, do not chooseAs follows: the cost of industrial aluminum material = the spot price of aluminum ingot, the processing cost of extrusion aluminum material, the freight of packing material. These are transparent, the cost of aluminum profiles are similar, significantly lower than the market price, the first possibility: the weight per meter less; second: aluminum is the use of recycled materials; third: material loss amplification (not according to the actual sales amount of meters).Second: only understand the sale material supplier does not chooseExplain as follows: preparing goods, recruit a few operator, big online promotion can be opened. Those who are often hurt are our buyers. Miss wiring mostly do not know how to use, only know the unit price. How to use to meet customer needs; how to make the most cost-effective; in different venues that kind of connection is the best; these are they can not answer accurately. Only know the cheapest and recommended profile connection the cheapest; this connection is the lowest cost, but the cost of artificial, a connection is the weakest, aluminum convenience wouldn't be reflected, and will bring much trouble for the future reconstruction. But the wiring girl will push it one way.Third: in production of aluminium supplierExplain as follows: in the production of aluminum suppliers, are generally engaged in this industry for more than 10 years, and their users have very rich experience, have a good understanding and knowledge of the quality and performance of products, suitable for the requirement of the customers will recommend price is a good product, choose a convenient and practical accessories.

- Q: This question asks for methods to ensure that aluminum profiles used in a construction project adhere to safety standards.

- <p>To ensure that the aluminum profiles used in your building project meet safety standards, you should source materials from reputable suppliers who provide certified products. Check for compliance with relevant standards such as ASTM, ISO, or local building codes. Request material certifications and test reports that confirm the profiles' strength, durability, and resistance to environmental factors. Engage a qualified engineer to review the specifications and design of the aluminum profiles to ensure they meet structural requirements. Conduct regular inspections during construction to verify that the profiles are installed correctly and are free from defects. Finally, maintain proper documentation of all materials and inspections to provide a traceable record of compliance with safety standards.</p>

- Q: Are aluminum profiles suitable for use in automotive body structures?

- Yes, aluminum profiles are suitable for use in automotive body structures. Aluminum is a lightweight and durable material that offers several advantages in the automotive industry. Its high strength-to-weight ratio makes it an ideal choice for constructing body frames, panels, and other structural components. Using aluminum profiles in automotive body structures offers benefits such as improved fuel efficiency, as the lighter weight of the material reduces the overall weight of the vehicle. This, in turn, allows for better acceleration and handling. Additionally, aluminum possesses excellent corrosion resistance, which is crucial for withstanding harsh environmental conditions and extending the lifespan of the vehicle. Furthermore, aluminum profiles can be easily shaped and formed into complex designs, allowing for greater design flexibility in automotive body structures. This versatility enables manufacturers to create more aerodynamic and visually appealing vehicles. While aluminum profiles offer numerous advantages, there are also some considerations to be aware of. Aluminum can be more expensive than traditional steel, which may impact the overall cost of the vehicle. Additionally, the repair and maintenance of aluminum structures may require specialized equipment and expertise. However, these factors are outweighed by the benefits aluminum profiles bring to the automotive industry. In conclusion, aluminum profiles are indeed suitable for use in automotive body structures. Their lightweight, durable, and corrosion-resistant properties, along with their design flexibility, make them an excellent choice for constructing modern vehicles.

- Q: What are the different welding options available for aluminum profiles?

- There are several welding options available for aluminum profiles, each with its own advantages and considerations. The most common welding methods for aluminum profiles include: 1. Tungsten Inert Gas (TIG) Welding: TIG welding is one of the most widely used methods for aluminum. It uses a non-consumable tungsten electrode to produce the weld, while an inert gas, such as argon, protects the weld area from atmospheric contamination. TIG welding offers excellent control over the heat input, resulting in high-quality, precise welds. It is suitable for thin aluminum profiles and provides a clean appearance, but it can be time-consuming and requires skilled operators. 2. Metal Inert Gas (MIG) Welding: MIG welding, also known as Gas Metal Arc Welding (GMAW), is another popular method for aluminum profiles. It uses a consumable wire electrode that continuously feeds into the weld pool, while an inert gas shield protects the weld area. MIG welding is faster than TIG welding and is suitable for both thin and thick aluminum profiles. However, it may produce more spatter and requires proper preparation and shielding gas selection. 3. Friction Stir Welding (FSW): Friction stir welding is a solid-state joining process that uses a rotating tool to generate heat and mechanically stir the aluminum profiles together. FSW is particularly suitable for thick aluminum profiles and offers high joint strength, excellent fatigue resistance, and minimal distortion. However, it requires specialized equipment and may not be suitable for all profile shapes. 4. Laser Beam Welding (LBW): Laser beam welding uses a highly concentrated laser beam to melt and join aluminum profiles. It provides a narrow and deep weld with minimal heat input, resulting in low distortion and high welding speeds. LBW is suitable for both thin and thick profiles, but it requires expensive equipment and skilled operators. 5. Resistance Spot Welding (RSW): Resistance spot welding uses electrical current and pressure to create welds by melting and joining aluminum profiles at specific points. RSW is commonly used for thin aluminum profiles and offers high productivity and repeatability. However, it requires access to both sides of the profiles and may leave visible marks on the surface. It is important to consider the specific requirements of your aluminum profile welding project, such as profile thickness, joint type, appearance, and production volume, to determine the most suitable welding method. Consulting with a welding professional or engineer can help ensure the best choice for your specific application.

- Q: What is the terminology to explain the aluminum twist and bending and a sharp respectively.

- The 3. longitudinal side camber: the largest plane profile on the platform, to achieve stability by self, at the ends of the side section had draw a straight line on the platform, measuring the maximum gap between this line and the side profile values for longitudinal side camber.A: can be completely surrounded by the profile of cross-section of the smallest circle.Manual input, for reference only, specific explanation can view GB/T 14846.

- Q: This question asks for a comparison between aluminum profiles and other building materials regarding their cost and performance.

- <p>Aluminum profiles are often more cost-effective than materials like steel or wood in the long run due to their durability and low maintenance requirements. They offer high strength-to-weight ratios, making them ideal for structures where weight is a concern. Additionally, aluminum profiles have excellent resistance to corrosion and weathering, which reduces the need for repainting or replacement over time. They are also energy-efficient, as they can help in reducing heat transfer, thus lowering energy costs for heating and cooling. However, the initial cost of aluminum profiles can be higher than some alternatives, but their long-term performance and low maintenance can offset this initial expense.</p>

- Q: This question asks for methods to protect aluminum profiles from corrosion and damage during the processes of transportation and storage.

- <p>To prevent corrosion and damage to aluminum profiles during transportation and storage, follow these guidelines: 1. Keep aluminum profiles dry and clean. Moisture and dirt can accelerate corrosion. 2. Use protective packaging, such as plastic wrap or padded covers, to shield profiles from physical damage and moisture. 3. Store profiles in a cool, dry place away from direct sunlight and corrosive substances. 4. Stack profiles with appropriate padding between layers to prevent scratching. 5. Avoid overloading during transportation and ensure secure fastening to prevent movement and potential damage. 6. Regularly inspect stored profiles for signs of corrosion or damage and address any issues promptly.</p>

Send your message to us

Wholesale Anodized Aluminum Profiles for Construction Application in Cars

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords