Wholesale Aluminum Sheets - Mill Finished Aluminum Coil Alloy AA3XXX for Building Outer Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finished Aluminum Coil Alloy AA3XXX for Building Ourter Doors

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC |

TEMPER | H14,H18,H24,H26,H32 |

THICKNESS | 0.2MM-20MM |

WIDTH | 10mm-1500mm |

COIL WGT | 2Mt - 3Mt |

Coil ID | 20" |

SURFACE | Mill finished etc |

STANDARD | GB/T 3880-2006 |

2. Application of Mill Finished Aluminum Coil Alloy AA3XXX for Building Ourter Doors

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finished Aluminum Coil Alloy AA3XXX for Building Ourter Doors

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

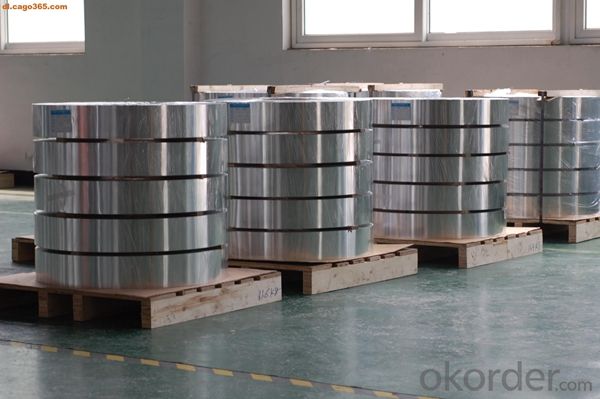

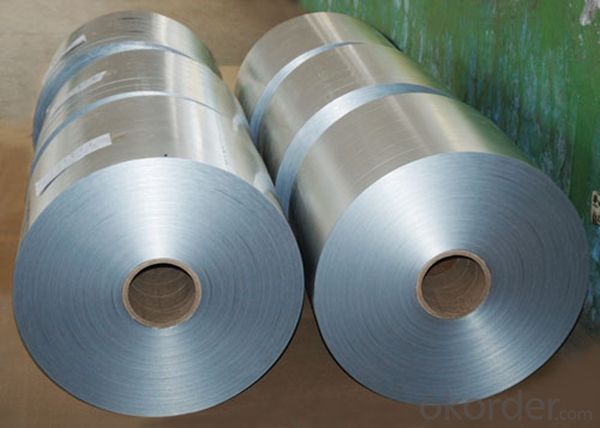

5. Image of Mill Finished Aluminum Coil Alloy AA3XXX for Building Ourter Doors

6. Package and shipping of Mill Finished Aluminum Coil Alloy AA3XXX for Building Ourter Doors

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: I have to wire solar DC photovoltaic panels and have always used at least an 8 gauge wire. Recently, I installed a solar electric fence and they recommended special electric fence wire that can handle 10,000 volts. It looks aluminum. The fence techs told me copper is only rated for 600 volts. And the power will leak through the insulation. They also say copper will corrode and created insulated spots. Does this mean that aluminum doesn't corrode and is it superior to copper? Is is all a lobbying scam to force us to buy copper? Can I use the electric fence wire in my solar wiring?

- I believe the fence techs are mistaken. On an electric fence, the wire is basically bare, and the periodic 10 kV shocks are very low current. Aluminum is cheap, and once it develops surface oxidation, will last. Copper would last, too - it would just cost more. For photovoltaic panels, copper is almost always the wire of choice. At #8 or larger, use stranded, of course. Copper has less resistance, which will be important in low-voltage PV. Also, aluminum wire cannot be simply put into fittings designed for copper; it must use special fittings designed for aluminum, or connected to copper with a wire nut and antioxidant.

- Q: Can aluminum sheets be used for decorative or architectural purposes?

- Yes, aluminum sheets can be used for decorative or architectural purposes. Aluminum is a versatile material that can be easily manipulated into different shapes and forms, making it ideal for various architectural applications. It is commonly used for exterior cladding, roofing, window frames, and facades, providing a sleek and modern aesthetic to buildings. Aluminum sheets can also be used for decorative purposes, such as wall panels, art installations, signage, and furniture. The lightweight and durable nature of aluminum make it a popular choice for architects and designers looking to create visually appealing and functional structures. Additionally, aluminum is resistant to corrosion, making it suitable for both indoor and outdoor applications.

- Q: Can aluminum sheets be an alternative to stainless steel?

- In certain applications, aluminum sheets can serve as a viable substitute for stainless steel. Aluminum, a lightweight metal, exhibits a favorable strength-to-weight ratio, making it suitable for various industries including aerospace, automotive, and construction. Similar to stainless steel, aluminum boasts a high level of corrosion resistance due to the formation of a protective oxide layer on its surface. When it comes to cost-effectiveness, aluminum sheets can prove advantageous over stainless steel, particularly in large-scale projects where reduced weight can lead to lower transportation and installation expenses. Furthermore, aluminum possesses excellent thermal and electrical conductivity, making it an appropriate choice for applications requiring such properties. Despite these advantages, stainless steel still outshines aluminum in certain aspects. Generally, stainless steel is stronger and more durable, rendering it suitable for heavy-duty applications or environments that demand high mechanical strength. Moreover, stainless steel exhibits superior resistance to extreme temperatures and fire, which can be critical in specific applications. In conclusion, while aluminum sheets can serve as an alternative to stainless steel in many scenarios, the ultimate selection hinges upon the specific requirements of the application, encompassing factors such as strength, durability, corrosion resistance, and cost.

- Q: What are the different types of alloys used for aluminum sheets?

- Aluminum sheets can be made from different types of alloys, each with its own unique properties and uses. Here are some of the most commonly used ones: - The 1100 alloy is pure aluminum and has excellent resistance to corrosion and good formability. It is often utilized for general sheet metal work like roofing and siding. - The 3003 alloy is similar to 1100 but contains added manganese, which makes it slightly stronger. It is commonly employed for applications that require moderate strength and good resistance to corrosion, such as packaging and automotive parts. - The 5052 alloy is renowned for its exceptional corrosion resistance, particularly in marine environments. It is also highly formable and weldable, making it suitable for various applications like fuel tanks, marine components, and architectural panels. - The 6061 alloy is one of the most versatile and widely used aluminum alloys. It offers excellent strength, weldability, and resistance to corrosion. It is commonly found in structural applications like aircraft parts, bicycle frames, and automotive components. - The 7075 alloy is a high-strength alloy frequently utilized in aerospace and military applications. It exhibits excellent resistance to fatigue and is easily machinable. It is typically employed for aircraft structures, missile parts, and high-stress components. These examples illustrate the variety of aluminum alloys available for sheet production. The choice of a specific alloy depends on desired properties, such as strength, resistance to corrosion, formability, and cost, as well as the intended application.

- Q: This question asks about the effects of using aluminum sheets in the construction industry on the environment.

- <p>The environmental impacts of using aluminum sheets in construction are multifaceted. On the positive side, aluminum is lightweight, which reduces energy consumption during transportation. It is also recyclable, with a high percentage of construction aluminum being recycled, reducing waste. However, the production of aluminum is energy-intensive, contributing to greenhouse gas emissions. Additionally, mining for bauxite, the primary source of aluminum, can lead to habitat destruction and water pollution. Despite these concerns, aluminum's durability and resistance to corrosion can extend the lifespan of buildings, reducing the need for frequent replacements and thus the overall environmental footprint over time.</p>

- Q: I just built a stone wall with illuminated glass features embedded, and to make them shine evenly, I had all sides but the visual one wrapped in industrial thickness aluminium foil. One week later, the foil has disintegrated. I have used type 10 Portland. What is going on?

- I believe your problem is that concrete acts as a fairly strong base (this is especially true of mortar mixes). It is well known that strong base will react with an active metal like aluminium and produce hydrogen gas as a byproduct. The representative reaction is: 2Al+6NaOH==2Na3AlO3+3H2, This reaction is fairly rapid and can even cause an explosive buildup of hydrogen gas in a non-ventillated area.

- Q: What are the different methods for engraving aluminum sheets?

- There are several methods for engraving aluminum sheets, including laser engraving, rotary engraving, chemical etching, and mechanical engraving. Each method offers unique benefits and can produce high-quality results depending on the desired outcome and specific requirements.

- Q: This question asks for methods to preserve an aluminum window and prevent rust or corrosion.

- <p>To maintain an aluminum window and prevent rusting or corrosion, follow these steps: Regularly clean the window with a mild detergent and water to remove dirt and grime. Avoid using abrasive cleaners or tools that could scratch the surface. Apply a protective coating or sealant designed for aluminum to shield it from moisture and environmental factors. Ensure proper drainage around the window to prevent water accumulation. Regularly inspect the window for signs of damage or corrosion and address any issues promptly. By following these maintenance practices, you can prolong the life of your aluminum window and keep it in good condition.</p>

- Q: 1) Aluminum ore is not formed in Quebec (why not?) 2)but aluminum ore is smelted into aluminum in Quebec. Why?

- The okorder

- Q: Are aluminum sheets suitable for marine vessel construction?

- Indeed, marine vessel construction can make use of aluminum sheets. Aluminum, a material that is both lightweight and strong, offers excellent resistance to corrosion in marine environments. It is commonly utilized in the construction of various marine vessels, including boats, ships, and yachts. The use of aluminum sheets in marine vessel construction has a significant advantage in terms of its high strength-to-weight ratio. This allows for the creation of lighter vessels, which can lead to improved fuel efficiency, increased speed, and enhanced handling. Additionally, the lightweight nature of aluminum facilitates easier transportation and maneuverability during the construction process. Another notable benefit of utilizing aluminum sheets for marine vessel construction is their exceptional resistance to corrosion. Aluminum naturally develops a protective oxide layer on its surface, which prevents further oxidation and corrosion. This makes aluminum an ideal choice for marine environments, where vessels are constantly exposed to saltwater, humidity, and other corrosive elements. Moreover, aluminum sheets can be easily fabricated and welded, providing flexibility in the design and construction of marine vessels. They can be shaped into various forms, allowing for the creation of intricate hull structures and interior components. Aluminum also possesses good thermal conductivity, which aids in regulating temperature within the interior spaces of marine vessels. While aluminum sheets offer numerous advantages for marine vessel construction, it is important to consider certain factors. Aluminum is susceptible to galvanic corrosion when it comes into contact with certain metals, such as steel or bronze. Therefore, proper insulation and anti-corrosion measures should be implemented to prevent galvanic corrosion in aluminum-based vessels. In conclusion, aluminum sheets are highly suitable for marine vessel construction. Their lightweight nature, high strength-to-weight ratio, resistance to corrosion, and ease of fabrication make them an ideal choice for building durable and efficient marine vessels. However, it is crucial to take proper precautions to prevent galvanic corrosion when aluminum is used alongside other metals.

Send your message to us

Wholesale Aluminum Sheets - Mill Finished Aluminum Coil Alloy AA3XXX for Building Outer Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords