Hindalco Aluminum Sheets - Mill Finished Aluminum Coil Alloy AA1xxx for Building Outer Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finished Aluminum Coil Alloy AA1XXX for Building Ourter Doors

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC |

TEMPER | H14,H18,H24,H26,H32 |

THICKNESS | 0.2MM-20MM |

WIDTH | 10mm-1500mm |

COIL WGT | 2Mt - 3Mt |

Coil ID | 20" |

SURFACE | Mill finished etc |

STANDARD | GB/T 3880-2006 |

2. Application of Mill Finished Aluminum Coil Alloy AA1XXX for Building Ourter Doors

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finished Aluminum Coil Alloy AA1XXX for Building Ourter Doors

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

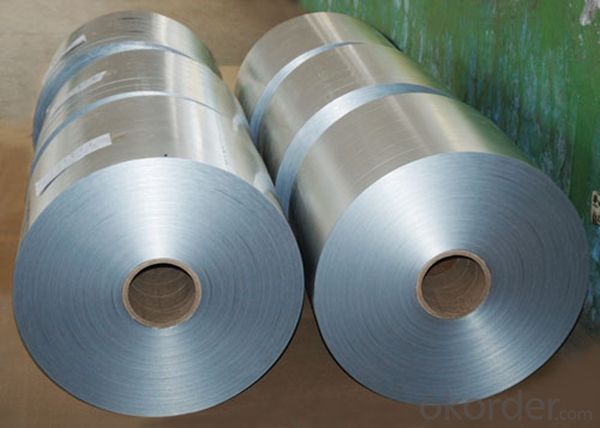

5. Image of Mill Finished Aluminum Coil Alloy AA1XXX for Building Ourter Doors

6. Package and shipping of Mill Finished Aluminum Coil Alloy AA1XXX for Building Ourter Doors

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: How does aluminum sheet perform in high-pressure applications?

- Due to its inherent properties, aluminum sheet is exceptionally effective in high-pressure applications. Its impressive strength-to-weight ratio makes it a suitable option for withstanding high-pressure environments. Additionally, aluminum exhibits excellent corrosion resistance, a crucial feature when dealing with high-pressure conditions that involve exposure to moisture or aggressive chemicals. Moreover, aluminum sheet is highly malleable, allowing it to be shaped and formed into various configurations to meet the specific requirements of high-pressure applications. Its flexibility enables it to endure the forces and stresses exerted during high-pressure processes without compromising its structural integrity. Furthermore, aluminum demonstrates good thermal conductivity, which aids in dissipating heat generated by high-pressure systems. This characteristic helps prevent overheating and ensures efficient operation. However, it is important to consider that the performance of aluminum sheet in high-pressure applications can be influenced by factors such as sheet thickness and alloy composition. Therefore, it is crucial to carefully select the appropriate grade and thickness of aluminum sheet based on the specific requirements and operating conditions of the high-pressure application. In conclusion, aluminum sheet is a dependable and efficient choice for high-pressure applications due to its strength, corrosion resistance, malleability, thermal conductivity, and overall performance under demanding conditions.

- Q: Can the aluminum sheets be used for manufacturing kitchen countertops?

- Certainly! Kitchen countertops can indeed be manufactured using aluminum sheets. Aluminum proves to be a versatile and durable material, displaying resistance against both corrosion and heat. Its lightweight nature and easy workability make it an ideal choice for crafting custom countertops in a variety of sizes and shapes. Moreover, aluminum countertops boast a contemporary and sleek appearance, while also being effortlessly cleanable and maintainable. Nevertheless, it is noteworthy that aluminum is comparatively softer when compared to other commonly utilized countertop materials like granite or quartz. Consequently, aluminum countertops may be more susceptible to scratches and dents. However, with proper care and maintenance, aluminum sheets can serve as a feasible alternative for producing kitchen countertops.

- Q: What types of aluminum sheets are recommended for outdoor use due to their properties?

- <p>Yes, there are specific types of aluminum sheets designed for exterior applications. These include aluminum sheets with protective coatings such as anodized aluminum, which offers enhanced resistance to corrosion and weathering. Additionally, aluminum sheets with a PVDF (Polyvinylidene Fluoride) coating, such as Kynar 500, are highly suitable for exterior use due to their excellent durability and resistance to UV rays, chemicals, and scratches. These coatings help maintain the aluminum's appearance and integrity over time, making them ideal for outdoor applications where exposure to the elements is a concern.</p>

- Q: How do aluminum sheets perform in terms of magnetism or electromagnetic interference?

- Aluminum sheets are considered to be non-magnetic and have low susceptibility to electromagnetic interference.

- Q: I have tried every possible one and every time i put it on it makes the smell 10x worse. It doesn't help at all it only makes it worse. Has ANYONE found one that actualy works? I hear that aluminum causes problems like alzheimer's.

- use a peach smelling 1 it works 4 me! thankz 4 the best awnser!!!!!!!!!!!!!!!

- Q: When water continually sprays on the aluminum sheet, how to avoid corrosion of aluminum sheet and keep its water resistance?

- Don’t worry about it, after aluminum contacts water or air, a layer of oxide film will generate on its surface to separate aluminum from the water or air and protect it, so it won’t be erosive.

- Q: Can aluminum sheets be anodized?

- Yes, aluminum sheets can be anodized. Anodizing is an electrochemical process that creates a durable, corrosion-resistant layer on the surface of aluminum. This process can be applied to aluminum sheets to enhance their appearance, increase their resistance to wear and tear, and improve their overall performance.

- Q: What are the different types of finishes available for painted aluminum sheets?

- Painted aluminum sheets come in various finishes, each with its own distinct features and advantages. 1. For a non-reflective and dull appearance, the matte finish is ideal. This option is commonly utilized in architectural elements and interior design for a low-gloss look. 2. If you prefer a shiny and reflective surface, the gloss finish is the way to go. This finish is often chosen for automotive parts and decorative panels, giving them a sleek and polished appearance. 3. To add texture and patterns to the painted aluminum sheet, opt for a textured finish. This type of finish is commonly used for decorative purposes, enhancing visual appeal and providing a unique tactile experience. 4. Achieve a metallic appearance resembling stainless steel or bronze with a metallic finish. This finish is frequently used in architectural applications to achieve a modern and high-end aesthetic. 5. Powder coating is a popular finishing method where a dry powder is applied to the painted aluminum sheet and cured under heat. This process creates a durable and seamless finish that is resistant to chipping, scratching, and fading. 6. Protect and enhance the durability of a painted aluminum sheet with a clear coat finish. This transparent finish provides an extra layer of protection against UV rays, moisture, and other environmental factors. Consider the intended use and desired aesthetic when selecting a finish for painted aluminum sheets, as each type offers its own unique benefits and characteristics.

- Q: What are the applications of aluminum sheet?

- Due to their unique properties and versatility, aluminum sheets have a wide range of applications. Some common uses include: 1. Construction: In the construction industry, aluminum sheets are widely utilized for roofing, siding, and cladding purposes. Their lightweight nature allows for easy handling and installation, while their corrosion resistance ensures durability over time. 2. Transportation: Aluminum sheets play a crucial role in the automotive industry by being extensively used in manufacturing vehicle bodies, panels, and structural components. Their high strength-to-weight ratio helps reduce overall vehicle weight, leading to increased fuel efficiency and improved performance. 3. Packaging: Within the packaging industry, aluminum sheets are commonly employed in the production of cans, foils, and containers. Aluminum foils, in particular, are utilized for food packaging as they provide a protective barrier against moisture, light, and oxygen, ensuring the freshness and safety of packaged products. 4. Electrical: The electrical industry relies on aluminum sheets for manufacturing power transmission lines, busbars, and electrical enclosures. Their excellent electrical conductivity aids in the efficient transmission of electricity, while their corrosion resistance allows for longevity in outdoor applications. 5. Marine: The marine industry extensively utilizes aluminum sheets for manufacturing boat hulls, decks, and superstructures. Their resistance to corrosion from saltwater makes them ideal for marine applications, and their lightweight nature helps reduce overall vessel weight. 6. Aerospace: In the aerospace industry, aluminum sheets are widely used for manufacturing aircraft and spacecraft components. Their high strength-to-weight ratio and excellent thermal conductivity make them suitable for applications where weight reduction and heat dissipation are critical. 7. Heat exchangers: Aluminum sheets are crucial in the manufacturing of heat exchangers, such as radiators and condensers. Their high thermal conductivity allows for efficient heat transfer, making them ideal for applications that require heat exchange. 8. Decorative: Aluminum sheets also find common use in interior design and architectural applications for decorative purposes. They can be easily shaped, bent, and formed into various designs, adding a modern and aesthetic appeal to buildings and interiors. In summary, aluminum sheets are extensively utilized in various industries due to their lightweight nature, corrosion resistance, high strength-to-weight ratio, and excellent thermal conductivity.

- Q: Are aluminum sheets suitable for automotive suspension components?

- Automotive suspension components can indeed be made from aluminum sheets, which offer numerous advantages. Firstly, aluminum sheets are much lighter than traditional steel components. This reduction in weight can lead to improved fuel efficiency and overall vehicle performance. By reducing the weight of suspension components, the vehicle's handling, acceleration, and braking can be enhanced, resulting in a smoother and more responsive ride. Secondly, aluminum possesses an excellent strength-to-weight ratio. This means that it can provide the necessary structural integrity and support for suspension components while still being lightweight. It has high tensile strength and stiffness, enabling it to withstand the stresses and forces exerted on suspension components during normal driving conditions. Furthermore, aluminum is highly resistant to corrosion, which is especially beneficial for automotive suspension components that are exposed to various environmental conditions. This corrosion resistance ensures the longevity and durability of the suspension system, reducing the need for frequent repairs or replacements. Moreover, aluminum is easily machinable, allowing for the creation of complex and intricate designs that can optimize suspension performance. Its flexibility in shaping and forming enables manufacturers to create suspension components with specific geometries and characteristics to meet the desired performance requirements. In conclusion, aluminum sheets are an excellent choice for automotive suspension components due to their lightweight nature, high strength-to-weight ratio, corrosion resistance, and machinability. These properties make aluminum a preferred material for suspension components, resulting in improved vehicle performance, fuel efficiency, and overall durability.

Send your message to us

Hindalco Aluminum Sheets - Mill Finished Aluminum Coil Alloy AA1xxx for Building Outer Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords