Mill Finished Aluminum Coil Alloy AA1xxx for Building Roofing - Aluminum Sheets Atlanta

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finished Aluminum Coil Alloy AA1XXX for Building Roofing

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC |

TEMPER | H14,H18,H24,H26,H32 |

THICKNESS | 0.2MM-20MM |

WIDTH | 10mm-1500mm |

COIL WGT | 2Mt - 3Mt |

Coil ID | 20" |

SURFACE | Mill finished etc |

STANDARD | GB/T 3880-2006 |

2. Application of Mill Finished Aluminum Coil Alloy AA1XXX for Building Roofing

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finished Aluminum Coil Alloy AA1XXX for Building Roofing

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

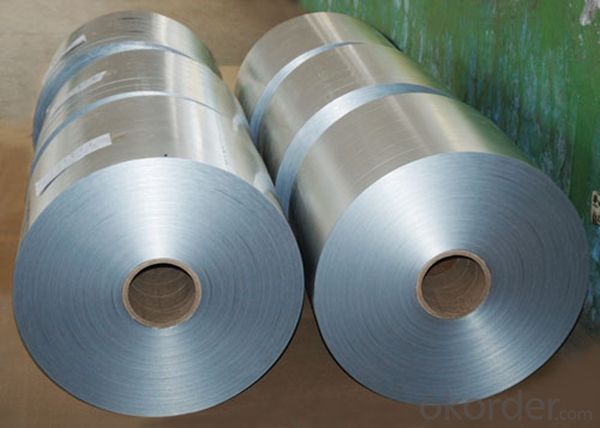

5. Image of Mill Finished Aluminum Coil Alloy AA1XXX for Building Roofing

6. Package and shipping of Mill Finished Aluminum Coil Alloy AA1XXX for Building Roofing

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are aluminum sheets resistant to vibration?

- Yes, aluminum sheets are generally resistant to vibration. Aluminum is a lightweight and flexible material that has good damping properties, meaning it can absorb and dissipate vibrations. Additionally, aluminum has a high strength-to-weight ratio, which allows it to retain its structural integrity even when subjected to vibrations. This makes aluminum sheets a popular choice in industries such as aerospace, automotive, and construction, where vibration resistance is important. However, it is worth noting that the specific resistance to vibration may vary depending on factors such as the thickness and alloy of the aluminum sheet, as well as the intensity and frequency of the vibrations.

- Q: What is the typical cost-effectiveness of aluminum sheets compared to other materials?

- Aluminum sheets are generally considered to be cost-effective compared to other materials. This is primarily due to their abundance, lightweight nature, and recyclability, which reduces production costs. Additionally, aluminum sheets offer a high strength-to-weight ratio, corrosion resistance, and durability, making them a popular choice across various industries. However, specific cost-effectiveness may vary depending on factors such as market demand, sheet thickness, and finishing requirements.

- Q: What are the common sizes of aluminum sheet?

- Common sizes of aluminum sheets vary depending on the specific requirements and industry applications. However, some standard sizes are commonly available in the market. These sizes typically range from 0.025 inches to 0.125 inches in thickness and can come in various widths and lengths. Some common width options include 36 inches, 48 inches, and 60 inches, while the length can range from 96 inches to 144 inches. Additionally, aluminum sheets can also be found in smaller sizes, such as 12 inches by 24 inches or 24 inches by 24 inches, which are often used for smaller projects or crafts. It is important to note that custom sizes can also be obtained through specialized aluminum sheet suppliers.

- Q: What is the typical tensile strength of aluminum sheets?

- The typical tensile strength of aluminum sheets can vary depending on the specific alloy and temper, but it is generally in the range of 20,000 to 45,000 pounds per square inch (psi).

- Q: Can 101 aluminum sheets be painted or coated?

- Certainly! Aluminum sheets offer the possibility of being painted or coated. This adaptable material lends itself to receiving a range of finishes, including paint or protective coating, which can both elevate its visual appeal and safeguard it against corrosion. Whether it pertains to 101 aluminum sheets or any other aluminum variant, diverse techniques like spray painting, powder coating, or anodizing can be employed to paint or coat them. The selection of the appropriate paint or coating shall be contingent upon the desired aesthetics, performance criteria, and the precise utilization of the aluminum sheets.

- Q: Aluminum or steel bike frame cost more???...which one cost the most usually???

- Good quality steel frames are almost always more expensive than aluminum. There are a couple of reasons for this... 1) Aluminum is always welded. This takes much less effort and time than a fine brazed steel unit; 2) High quality steel tubing is very expensive compared to aluminum due to the thin walls and sometimes exotic alloying materials; 3) Aluminum is one of the most common elements on the planet. Common steel alloys have harder-to-obtain elements such as molybdneum, manganese, and other rare metals. 4) Although many aluminums require post weld processing it takes little or no labor to complete it while a high quality steel frame responds beautifully to hand work. 5) A good steel frame is simply harder to find nowadays. I know that this goes beyond the scope of your question, but keep in mind that regardless of the aluminum alloy it all weighs the same; regardless of the steel alloy it all weighs the same. The difference in weight comes from modifying the metal mixture, enabling a stronger metal and making of ever-thinner tubes. Kojman47 (below) is WAAY off in his interpretation of materials. There are steel frames that rival the weight and strength of titanium which is often 1/2 the weight of aluminum. There is no such thing as cromolly. The correct name (if I may) is Chrome Molybdneum, abbreviated as CrMo, often called Chrome Moly. Cromoly or cromolly or cromo doesn't give proper respect to the alloy OR to the frame. CrMo (cromolly in Kojmans eyes) is steel.

- Q: combines with oxygen with an atomic weight of 16, to form the compound aluminum oxide, how much oxygen would be required to react completely with 54g of aluminum?

- Well, Al2O3 is the formula for aluminum oxide So you have 2 moles of Al, so you need 3 moles of O which is 1.5 moles of O2 So the answer is 48g

- Q: What is the color range available for aluminum sheets?

- The color range available for aluminum sheets is vast and diverse, including options like silver, white, black, gold, bronze, copper, blue, red, green, and many more.

- Q: How do I calculate the weight of aluminum sheet? What is the density?

- The density of aluminum is 2.7g/cm^3.

Send your message to us

Mill Finished Aluminum Coil Alloy AA1xxx for Building Roofing - Aluminum Sheets Atlanta

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords