Wearable Black Treadmill Walking Belts PVC Conveyor Belts for Fitness,Gym

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Wearable Black Treadmill Walking Belts PVC Conveyor Belts for Fitness,Gym

Description of Treadmill Conveyor Belt

Our company introduced and use the most advanced production technology which are extrusion method,lamination method and calendering method to produce light duty PVC, PU and PE conveyor belts, compared with the other factories using the traditional coating method, our belts have more advantages:1. high flatness, the height flatness is within ±0.05mm;2. high density;3. high tensile strength;4.reliable splice, it can reach the same service life as the original;5.good performance of anti-abrasion and chemical&oil resistance.

Especially suitable for material conveying at inflammable of underground coal mines.The fabric is high in strength and low in elongation and the light carcass is shock resistant, anti-tear and good in trough ability

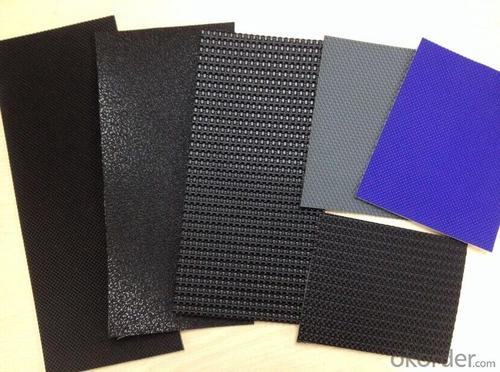

Surface Patterns:

Flat, Grass , Golf, Diamond, Matte surface finish, Small round particles and etc.

Features of Treadmill Conveyor Belt

thickness:1.4 1.6 1.8 2.0 2.3 2.5 3.1 4.3 4.5 mm

household treadmill: 1.8 2.0 2.3mm

gym treadmill:2.5 3.1 4.3 4.5mm

surface: diamond

color: black blue red grey

Applications of Treadmill Conveyor Belt

Widely used in the Conveyance and production assembly lines in the areas

of airports, postal automation, parcel handling, treadmills, packaging/wrapping, cigarettes,

tobacco,leather, foodstuffs, drinks, medicine,chemical,tyre ,electronics, pharmaceutical,

printing,papermaking, wood, stone/marble, entertainment industry and fishery industry etc.

Know your Treadmill Conveyor Belt

A damaged or worn out belt can be dangerous for you and can quickly wear out electrical components of the treadmill.It is better to replace the belt than to risk an injury or more costly repair.

If your belt is running slow, or feels loose, you may assume that the belt needs to be replaced. Often, though, these are indicators of too tight or too loose tension rollers, and can be fixed by either tightening or loosening the tension rollers.

Pictures of PVC Treadmill Conveyor Belt

RFQ:

Q: Can you do OEM?

A: Yes, we can do OEM products. It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the

samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS,

DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you

can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1).All raw material we used are environmental-friendly;

2).Skilful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance upon the B/L copy .

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the PVC treadmill conveyor belt, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q: Is mixed silicone rubber dangerous?

- Mixed silicone rubber silicone rubber is the synthesis of silicone rubber crosslinking agent + + + + auxiliary catalyst filler in the double roller mixer or a sealed kneading machine.

- Q: Rubber Mooney value is what meaning, what is the role of

- In accordance with the provisions of the standard GB 1232 (Mooney viscosity), rotation expressed by the symbol Z100 C 1+4. Where Z rotational viscosity; 1, preheating time is 1min; 4 - rotation time is 4min; 100 C - test temperature of 100 degrees.In our country, usually with ML100 or MS100 1+4 to 1+4 DEG C said. M said L Mooney, represented by the greater trochanter, S said with a small rotor.1 preheat for 1 minutes, 4 said that the test for 4 minutes. The larger the value of Mooney viscosity, said, the plastic is widely used as a low. Index control process performance of rubber.

- Q: Rubber soaked with hot water will not come out harmful substances?

- Chloroprene rubber is electrical insulation, cold resistant performance is poor, rubber is not stable in storage. Neoprene is widely used, such as the manufacture of transport belts and belts, wires and cables, and the manufacture of oil resistant hoses, gaskets, and chemical resistant equipment linings.

- Q: Why do rubber products Blister?

- As the temperature is too high, the rubber organic matter boiling point is low, and then because of pressure, it will increase the internal energy, leading to temperature rise.As long as the temperature is lowered and the pressure is right, you can try not to blister

- Q: How does the rubber part of the watch become yellow?

- It is mainly divided into two kinds of natural rubber and synthetic rubber. Natural rubber is made from rubber, rubber and grass. Synthetic rubber is obtained by polymerization of various monomers. Rubber products are widely used in industry or in all fields of life. It has a wide range of uses. [1] can also be divided into rubber with natural rubber, general rubber, styrene butadiene rubber, nitrile rubber, silicone rubber, butadiene rubber, butyl rubber, EPDM rubber, chloroprene rubber types.

- Q: How to remove the rubber front?

- At present, there are two kinds of machine trimming on the market: roller grinding and cold trimming at normal temperature. If the product added value is not high, not strong to Feng processing precision, recommended by the economic roller milling Xiu Feng, this is the products into the drum, small friction rub off Feng ball and rely on some products produced by each other. The advantage of this approach is that it is relatively economical.

- Q: Properties and specific uses of various rubbers

- Synthetic rubber is made by synthetic methods, and different kinds of rubber can be synthesized with different raw materials (monomers). Such as, butadiene rubber, chloroprene rubber, styrene butadiene rubber and so on. The yield of synthetic rubber has greatly exceeded that of natural rubber, of which the largest yield is styrene butadiene rubber.

- Q: How do you remove the rubber on your new slippers?

- There must be some rubber smell, because the bottom containing rubber and plastic bags are used as fine without air so the rubber flavor will be heavier, and you wear for a period of time will not fall, or to buy after put in place of ventilation blowing for one or two days no taste.

- Q: How to distinguish between plastic products and rubber products, toys?

- There are several ways to distinguish between plastic and rubber products:1, color: plastic products, relatively transparent color, relatively strong, and rubber products are relatively poor transparency;2, thickness: plastic product thickness than rubber products thin;3 hardness: general plastic products than rubber products slightly hard;4: texture: plastic products are more smooth or microstrip lines, and rubber products on the surface of some of the same as human skin, texture deeper or more rough;5, taste: plastic taste, the taste of micro strip plastic, and rubber products are micro rubber rubber flavor;6, weight: general plastic products will be slightly lighter than rubber products.

- Q: What is the difference between rubber expansion joint and rubber joint?

- It is divided into 3 kinds: flange type, fixed flange type and thread type by connection. The structure can be divided into single sphere, double sphere and curved sphere. A tubular rubber component is composed of inner and outer layers of rubber, cord and steel ring, which is vulcanized and molded and then combined with a metal flange or a parallel joint. This product can reduce vibration and noise, and can be compensated by thermal expansion and cold contraction due to temperature changes. It is widely used in various piping systems. Rubber joint is a kind of pipe joint with high elasticity, high air tightness, medium resistance and weather resistance. The product uses rubber elasticity, high air tightness, medium resistance, weather resistance and radiation resistance etc., using polyester cord fabric skew high strength, strong stability and the hot and cold composite, after high pressure, mold temperature and curing. As the rubber joint has good comprehensive performance, it mainly acts as shock absorption, noise elimination and noise reduction. Therefore, it is widely used in chemical, construction, water supply, drainage, petroleum, light and heavy industries, freezing, sanitation, plumbing, fire fighting, power and other infrastructure projects.

Send your message to us

Wearable Black Treadmill Walking Belts PVC Conveyor Belts for Fitness,Gym

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords