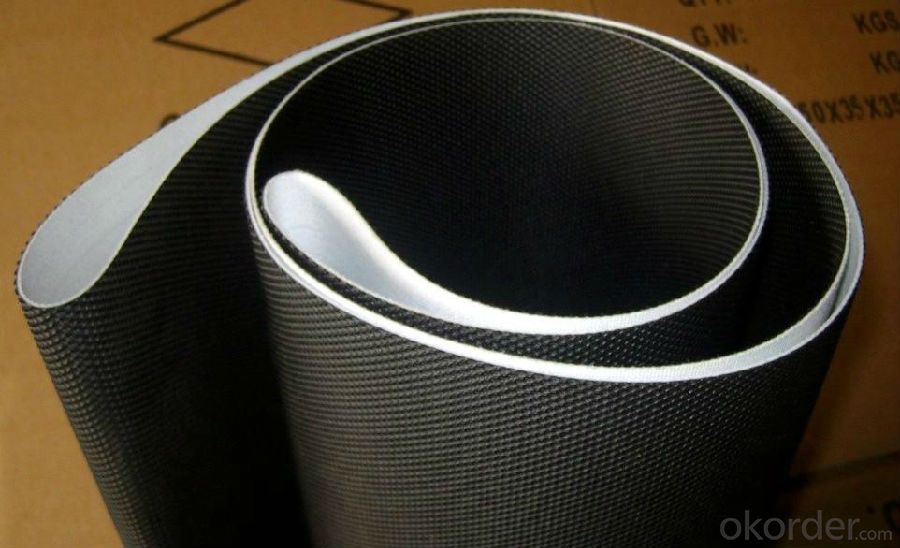

Wearable Treadmill Walking Belts PVC Conveyor Belt Running Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Wearable Treadmill Walking Belts PVC Conveyor Belt Running Belt

1.Product Description:

Our Treadmill conveyor belts are manufactured using high quality material.It features largely in the high strength, stable conveyance performance. Easy setting and cleaning, Competitive price and high quality.Besides, it is fire retardant, anti-static, shock resistant, wearable and corrosion resistant.

2.Product Advantages:

1).Our treadmill conveyor belts need no lubrication and run quietly and smoothly – without noise or tracking problems.

2).Our treadmill conveyor belts combine low energy sonsuption with durability and an excellent appearance

3.Product Feature:

*Anti-static and non-conductive

*Food quality types to FDA standards

* Working temperature ranges from -10 to 80Deg.C

*Resistance to abrasion, oils, fats and chemicals

*Surfaces with low, medium or high coefficient of friction

*High transverse rigidity and dimensional stability

* Low noise

4.Applications:

Widely used in the Conveyance and production assembly lines in the areas

of airports, postal automation, parcel handling, treadmills, packaging/wrapping, cigarettes,

tobacco,leather, foodstuffs, drinks, medicine,chemical,tyre ,electronics, pharmaceutical,

printing,papermaking, wood, stone/marble, entertainment industry and fishery industry etc.

Pls contact me freely if any inquiry or questions,thank you!

- Q: How can I remove the rubber flavor on rubber products? It smells terrible

- Different types of rubber deodorant by different chemical AO and effect, which can effectively remove all kinds of rubber, including reclaimed rubber, flame retardant rubber smell in the processing and use of rubber products, improve the level of environmental protection, applicable to all kinds of rubber molding process. The utility model has the advantages of low use, high efficiency, safety and innocuity

- Q: Is silicone good or rubber good?

- We can see from their properties, silicone rubber has the superiority of the ordinary rubber silicone rubber prices There is nothing comparable to this, more expensive, which is better, we should look at our purpose, if ordinary rubber products can meet our needs, it is not necessary to overkill, with better performance, higher prices of the silica gel.

- Q: How to maintain and store the rubber material?

- When storing, matters needing attention are:(1) should be stored in a ventilated, dry environment, the relative humidity of the air is 50% ~ 80%.(2) should be stored in non corrosive media, and away from the heat source, the temperature is about 5 degrees Celsius conditions(3) packing should be kept as far as possible without box stacking

- Q: Aging of rubber parts for automobiles

- The engine bracket, the foot pad, the leaf spring bushing, and the shock absorbing foot cushion, such as rubber aging, will vibrate abnormally and cause abnormal noise, which will cause the damage of the whole component and even the radiation to the surrounding parts. In addition, the rubber bushings on the trucks need to be replaced, it is not an easy task and sometimes requires larger actions. For example, the shock absorber rubber of the cab needs to be lifted if it needs to be replaced.

- Q: How are rubber wires processed?

- [summary] the main raw material is rubber, rubber products with various agents, as well as the fiber and metal skeleton material, the basic production process of rubber products including plastication, mixing, calendering, extrusion, molding, curing 6 basic processes.The processing process of rubber is mainly to solve the process of plastic and elastic contradictions, through various means of processing, the elastic rubber has become the plastic rubber, adding various in the preparation of semi-finished products, and then through the vulcanization is has semi-finished plastic and rubber products into high elasticity and good mechanical performance the.

- Q: What is the size of the scorch time of the rubber?

- Scorch time, or T10, is the time required for torque to reach 10%. Scorch is the phenomenon of early vulcanization occurring in the processing of rubber compound.

- Q: Half finished rubber film surface white is going on

- Rubber is a latex made from rubber, tree, rubber, and grass. It is made of flexible, insulating, impermeable and air. High elastic polymer compound. It is divided into two kinds: natural rubber and synthetic rubber. Natural rubber is made from rubber, tree, rubber, grass and other plants. The synthetic rubber is obtained by polymerization of various monomers. Rubber products are widely used in industry or in all fields of life.

- Q: How long does the rubber last?

- In addition, aging has ozone aging, weather aging, heat aging and so on. Ding Qing rubber is not resistant to ozone, the time is not long, it will appear aging.

- Q: For the application of common synthetic rubber, not too long or too difficult, want to do

- Isoprene rubber (IR) is a kind of structure of rubber from the CIS isoprene monomer polymerization. The chemical composition, and three-dimensional structure of natural rubber is similar to that of the performance is very close to the natural rubber, synthetic natural rubber said. It has most of the advantages of natural rubber, aging due to natural rubber elasticity and strength. Slightly lower than natural rubber, poor processing performance, high cost. Use temperature range: - 50 DEG C ~ + 100 DEG C can be used instead of natural rubber tires, rubber shoes, rubber hose, making tape and other generic products.

- Q: What is the difference between PVC rubber and ordinary rubber?

- PVC is polyvinyl chloride (with "green" sound) vinyl, English PVC (Polyvinyl chloride), is a vinyl chloride monomer (vinyl chloride monomer, referred to as VCM) in peroxide, such as azo compound initiator; or in light, under the action of heat polymerization by free radical reaction mechanism of polymerization of polymers.

Send your message to us

Wearable Treadmill Walking Belts PVC Conveyor Belt Running Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords