Light Duty Black Treadmill PVC Conveyor Belt Treadmill Walking Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Light Duty Black Treadmill PVC Conveyor Belt Treadmill Walking Belt

Description of Treadmill Conveyor Belt

Our company introduced and use the most advanced production technology which are extrusion method,lamination method and calendering method to produce light duty PVC, PU and PE conveyor belts, compared with the other factories using the traditional coating method, our belts have more advantages:1. high flatness, the height flatness is within ±0.05mm;2. high density;3. high tensile strength;4.reliable splice, it can reach the same service life as the original;5.good performance of anti-abrasion and chemical&oil resistance.

We offer a variety of different treadmill belt types to meet diverse technical and commercial needs. The range includes traditional treadmill belts as well as maintenance-free types for commercial and institutional treadmill units.

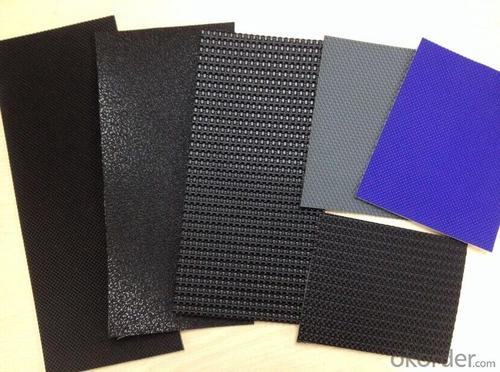

Patterns:

Flat, Grass , Golf, Diamond, Matte surface finish, Small round particles and etc.

Features of Treadmill Conveyor Belt

has excellent abrasion resistance.

has excellent chemical resistance; excellent shock resistance; hardness constant, long service life.

non-toxic, tasteless, can be customized color.

comply with ROHS environmental requirements.

Applications of Treadmill Conveyor Belt

Widely used in the Conveyance and production assembly lines in the areas

of airports, postal automation, parcel handling, treadmills, packaging/wrapping, cigarettes,

tobacco,leather, foodstuffs, drinks, medicine,chemical,tyre ,electronics, pharmaceutical,

printing,papermaking, wood, stone/marble, entertainment industry and fishery industry etc.

Pictures of PVC Treadmill Conveyor Belt

RFQ:

Q: Can you do OEM?

A: Yes, we can do OEM products. It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the

samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS,

DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you

can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1).All raw material we used are environmental-friendly;

2).Skilful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance upon the B/L copy .

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the PVC treadmill conveyor belt, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q: What is the tensile strength of silicone rubber?

- Silicone rubber is a kind of elastomer with molecular backbone, -Si-O- inorganic structure and side group as organic group. Silicone rubber is a semi inorganic, saturated, mixed, non-polar elastomer.

- Q: What is the cause of the bursting of rubber products and how should they be improved?

- There are five reasons for the bursting of rubber products: 1. forming temperature is too high, or the temperature of the upper and lower template is inconsistent. 2. the exhaust line is too open or exhaust time is too late. 3., the material quickly cooked. 4., the mold structure is irrational, there is no running trough. 5., down weight, overweight.

- Q: What are the uses of rubber oil?

- Application: mainly used as rubber softener. The effect of carbon black rubber products: rubber materials have good dispersing effect of softening rubber, increase the viscosity, make the rubber soft and smooth, and can improve the anti corrosion performance of coke products cold, another of the thiazole accelerator can increase the activation effect of complexing agent

- Q: Why do rubber products Blister?

- As the temperature is too high, the rubber organic matter boiling point is low, and then because of pressure, it will increase the internal energy, leading to temperature rise.As long as the temperature is lowered and the pressure is right, you can try not to blister

- Q: What's the difference between silicone rubber and 703.704 glue?

- 703, temperature range of -50-150, water resistance, salt water effect is good, mainly used for cable potting, instrument waterproof seal, watchcase bonding;

- Q: How to test the abrasion resistance of rubber?

- It is mainly divided into two kinds of natural rubber and synthetic rubber. Natural rubber is made from rubber, rubber and grass. Synthetic rubber is obtained by polymerization of various monomers. Rubber products are widely used in industry or in all fields of life. It has a wide range of uses. [1] can also be divided into rubber with natural rubber, general rubber, styrene butadiene rubber, nitrile rubber, silicone rubber, butadiene rubber, butyl rubber, EPDM rubber, chloroprene rubber types.

- Q: What's rubber skin?

- The general rubber has good comprehensive properties and is widely used. The main contents are as follows: natural rubber. From the latex of the Hevea tree, the basic chemical composition is cis polyisoprene. Good elasticity, high strength and good comprehensive performance. Isoprene rubber. The full name is cis -1, 4- polyisoprene rubber, a high CIS synthetic rubber made from isoprene, because of its structure and properties similar to natural rubber, it is also called synthetic natural rubber. Styrene butadiene rubber. Referred to as SBR, made by copolymerization of butadiene and styrene. According to the production method, emulsion polymerization, styrene butadiene rubber and solution polymerized styrene butadiene rubber are divided into emulsion polymerization. Its comprehensive properties and chemical stability are good. The br. The full name is cis -1, 4- polybutadiene rubber, referred to as BR, made from butadiene polymerization. And the other than universal rubber, vulcanized butadiene rubber cold resistance, abrasion resistance and excellent elasticity, dynamic load, less heat, good aging resistance, easy and natural rubber, chloroprene rubber, nitrile rubber and etc..

- Q: How can rubber products prevent fading?

- That is to add UV absorbers, white, then add more titanium dioxide, there is no good way, as well as your choice of pigment, as far as possible difficult to fade, such as inorganic pigments.

- Q: How can rubber be made into rubber when it is made?

- Rubber made of rubber products, to be mixed, vulcanized, trimming and many other processes to make rubber products, is a complex processing plant produced.

- Q: What is the temperature of ordinary silicone rubber resistant to low temperature?

- Heat resistance of silicone rubber in the air is much better than that of organic rubber, at 150 DEG C, the physical and mechanical properties basically unchanged, semi permanent use, under the temperature of 200 DEG C can be used continuously for more than 10000h; 380 DEG C can be used for some time. Silicone rubber is therefore widely used as rubber parts in high temperature applications.

Send your message to us

Light Duty Black Treadmill PVC Conveyor Belt Treadmill Walking Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords