Black PVC Treadmill Conveyor Belt Running Belt for Fitness

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Black PVC Treadmill Conveyor Belt Running Belt for Fitness

Description of Treadmill Conveyor Belt

Our company introduced and use the most advanced production technology which are extrusion method,lamination method and calendering method to produce light duty PVC, PU and PE conveyor belts, compared with the other factories using the traditional coating method, our belts have more advantages:1. high flatness, the height flatness is within ±0.05mm;2. high density;3. high tensile strength;4.reliable splice, it can reach the same service life as the original;5.good performance of anti-abrasion and chemical&oil resistance.

We offer a variety of different treadmill belt types to meet diverse technical and commercial needs. The range includes traditional treadmill belts as well as maintenance-free types for commercial and institutional treadmill units.

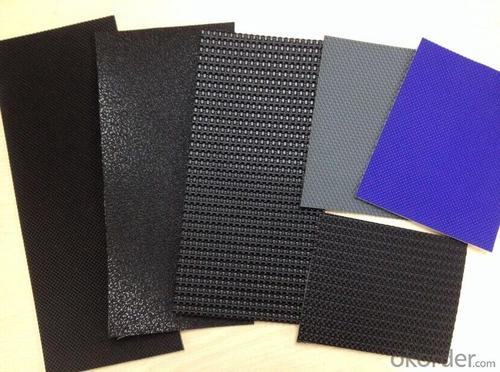

Surface Patterns:

Flat, Grass , Golf, Diamond, Matte surface finish, Small round particles and etc.

Features of Treadmill Conveyor Belt

thickness:1.4 1.6 1.8 2.0 2.3 2.5 3.1 4.3 4.5 mm

household treadmill: 1.8 2.0 2.3mm

gym treadmill:2.5 3.1 4.3 4.5mm

surface: diamond

color: black blue red grey

Applications of Treadmill Conveyor Belt

Widely used in the Conveyance and production assembly lines in the areas

of airports, postal automation, parcel handling, treadmills, packaging/wrapping, cigarettes,

tobacco,leather, foodstuffs, drinks, medicine,chemical,tyre ,electronics, pharmaceutical,

printing,papermaking, wood, stone/marble, entertainment industry and fishery industry etc.

Know your Treadmill Conveyor Belt

A damaged or worn out belt can be dangerous for you and can quickly wear out electrical components of the treadmill.It is better to replace the belt than to risk an injury or more costly repair.

If your belt is running slow, or feels loose, you may assume that the belt needs to be replaced. Often, though, these are indicators of too tight or too loose tension rollers, and can be fixed by either tightening or loosening the tension rollers.

Pictures of PVC Treadmill Conveyor Belt

RFQ:

Q: Can you do OEM?

A: Yes, we can do OEM products. It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the

samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS,

DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you

can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1).All raw material we used are environmental-friendly;

2).Skilful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance upon the B/L copy .

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the PVC treadmill conveyor belt, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q: What's the difference between rubber and silicone?

- Different types and grades of rubber applications are not the same, such as natural rubber is mainly used to make tires, butyl rubber mainly in the tube, three yuan ethylene propylene rubber for sealing products.

- Q: What are the differences in the properties of neoprene models?

- Good physical and mechanical properties, oil resistance, heat resistance, fire resistance, sunlight resistance, ozone resistance, acid and alkali resistance, chemical reagents. The disadvantage is cold resistance and poor storage stability. With high tensile strength, elongation and reversible crystallinity, good adhesion. Aging resistance, heat resistance. Excellent oil resistance and chemical resistance. Weatherability and ozone resistance are second only to that of ethylene propylene rubber and butyl rubber. The heat resistance and the nitrile rubber, the decomposition temperature of 230~260 DEG C, short-term resistance at 80~100 DEG 120~150 DEG C, can be used for a long time, with a certain flame retardancy. Oil resistance second only to nbr. Good resistance to inorganic acids and alkalis. Cold resistance is slightly worse, electrical insulation is poor. Rubber poor storage stability, will have a "sulfur" phenomenon, Mooney viscosity increased, hard rubber. Foreign brands are: AD 1, 30 (USA), A-90 (Japan), 320 (Germany), and MA40S (France).

- Q: What does the rubber tire do to people?

- Rubber is divided into natural rubber and synthetic rubber according to its raw material. According to the form is divided into block rubber, latex, liquid rubber and rubber powder. Latex as a rubber colloidal water dispersion; liquid rubber as an oligomer of rubber, not before the vulcanization is generally viscous liquid; powder rubber is the latex processing into powder, in order to benefit ingredients and processing. Thermoplastic rubber, developed in 1960s, does not require chemical vulcanization and is shaped by thermoplastic processing. Rubber according to the use of divided into general and special type of two categories. It is not easy to insulator, conductive, but if water or different temperature, are likely to become a conductor. Conduction is the conduction of electrons in a substance, molecule, or ion.

- Q: When rubber products are hardened, what methods soften?

- Either hardening or vulcanization. Vulcanized rubber becomes elastic rubber. This is an irreversible process. The elastomer can be changed into a plastic regenerated rubber by the desulfurization process.

- Q: What's the difference between silicone products and rubber products?

- The materials used are different: in other industries, the rubber products used are nitrile rubber, and the silica gel products are made of silica gel.

- Q: What are the applications of rubber airbags in the automotive field?

- Rubber accounts for 5% of the total weight of automotive materials, with an average of 100200 rubber parts per car, with a total number of 200500. Along with the automobile reliability, environmental protection and energy saving requirements continue to increase, and rubber materials, product structure optimization, improve the heat resistance, low temperature resistance, long aging, oil resistance, leakage resistance, long-term fatigue, and further reduce the cost has become the main topic of the development of automotive rubber. Fluorine rubber, silicone rubber, acrylic rubber and other special heat-resistant elastic body will still be the mainstream of the future direction of the development of automobile rubber.

- Q: What gum does rubber and metal stick together?

- JL-480 black rubber instant glue: medium viscosity, high strength, etc. used for inert surface, bonding, porous, acid, vibration and heat resistance, rubber, metal, plastic bonding. The utility model can be used for large gaps and more dispensing. High viscosity, impact resistance. The curing is slow, the curing has toughness, and the adhesive force is strong. After bonding, the adhesive surface can reach two and the adhesive surface dissolves as a whole. It is a shock resistant instant adhesive, which has better seismic and stripping strength than other series. Widely used, bonding rubber, plastic, and metal as adhesive for impact resistance. It is more flexible than conventional adhesive.

- Q: Is the odour emitted by industrial rubber poisonous?

- Rubber production process including plastic, mixing, rolling or extrusion, molding and vulcanizing and other basic processes, each process for the products have different requirements, respectively, with a number of auxiliary operations.

- Q: How to solve the exhaust problem in rubber vulcanization process

- Rubber vulcanization process is a process of high temperature, temperature control, temperature will have material evaporation, products not dense gap, excess glue extrusion emissions, sulfide gas release of many factors such as rubber vulcanization requirements must exhaust can produce qualified products.

- Q: How can rubber be made into rubber when it is made?

- Just cut off the rubber is not available, belongs to the first rubber, according to the products and the use of working conditions to set the formula, made of mixed rubber, vulcanized on the vulcanization machine with mold has been good, curing after trimming, testing, packaging. The required rubber products will be ready.The process flow of the production process is:Raw material preparation, plasticization, blending, molding, vulcanizing, cleaning and testing

Send your message to us

Black PVC Treadmill Conveyor Belt Running Belt for Fitness

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords