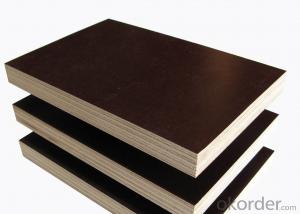

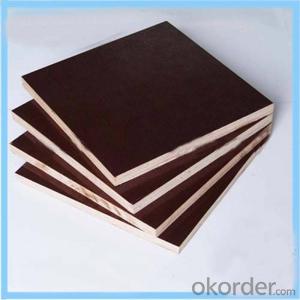

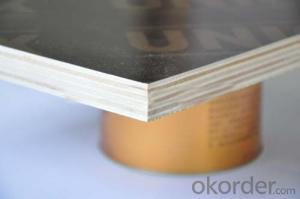

WBP Black Film Faced Plywood 15mm Marine Plywood

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details:

· Type: Plywood

· Place of Origin: Shandong, China (Mainland)

· Brand Name: buildplex

· Usage: Outdoor

· Grade: First-Class

· Main Material: Poplar

· Plywood Type: Other

· Size: 1220x2440mm,1250x2500mm

· Thickness: 18mm,9mm 12mm, 15mm,21mm

· Core: poplar

· Glue: WBP

· Cycle life: 2-4 times uses

· Film: brown,black,red

· Moisture: below 16%

Packaging & Delivery:

Packaging Details: | Standard Export Packing ; Plywood wrapped in 3mm plywood, tied tightly with steel/plastic strips and edges producted with edge protectors. Plywood on pallets. |

Delivery Detail: | within 20 days after receiving LC or deposit |

Product Specification:

Product Name | Film faced plywood |

F/B | Black film, brown film, red film |

Grade | First grade |

Core | poplar |

Glue | WBP |

Thickness | 8-21mm |

Specification | 1220x2440mm, 1250x2500mm |

Moisture Content | 8-13% |

Package | Standard export package on pallet |

Certification | ISO9001 |

MOQ | 1x40HQ |

Price Terms | FOB, CIF,CNF |

Payment | T/T, 100% irrevocable LC |

Delivery Time | Within 20 days after order confirmed |

Supply Capacity | 5000CBM/month |

Usages | Can be widely used for building concrete, etc |

Remarks | Top class equipment with top class produce technique Credit first, fair trading |

No | Property | Unit | Test Standard | Value of Test | Result | |

1 | Moisture content | % | EN322 | 10 | Check out | |

2 | Density | Kg/m3 | EN322 | 530 | Check out | |

3 | Bonding quality | Bonding quality | Mpa | EN314 | Max:1.27 Min:0.6 | Check out |

Damage rate | % | GB/T17656-1999 | 60% | |||

4 | Bending modules of elasticity | Longitudinal | Mpa |

EN310 | 5800 | Check out |

Lateral | 4500 | |||||

5 | Bending strength(N/mm) | Longitudinal | 40.1 | Check out | ||

Lateral | 33.2 | |||||

6 | Cycle Life | About 2-4 repeated using times according projects by formwork application | ||||

Product Pictures:

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Our Mission: provide customers with high quality and service!

- Q: Color steel sandwich panels are prefabricated or on-site production processing

- This is based on the specifications you want to color steel sandwich panels to customize, and some factories if you just need the specifications, then there may be spot Oh

- Q: Caigang glass wool cotton sandwich panels are non - burning materials do

- Caigang glass wool cotton sandwich panels are non-burning materials, Caigang glass wool sandwich panels and rock wool sandwich panels belong to the same fire board.

- Q: How about the use of colored steel sandwich panels on the balcony

- Can you, inexpensive. Just when the rain is relatively large noise, lighting effect is not ideal If the conditions permit, then recommend the use of glass, 5 +5 plus plastic on the line. The price difference of about 30%. Life is longer than the color steel, low noise, good lighting.

- Q: Color steel rock wool sandwich board price how much

- The price by region, quality and demand to go, Tianjin is rock wool board manufacturers more cities, a single rock wool board, then many can do 40 or so per square meter

- Q: What is the meaning of the bulk density of double-sided color steel polyurethane panels?

- Bulk density of polystyrene foam board should be ≥18kg / m; Polyurethane double sided steel plate Metal surface sandwich panel metal surface sandwich panel metal surface sandwich panel metal surface sandwich panel 1 product definition product definition product definition product definition metal surface sandwich panel refers to the upper and lower layers of metal sheet, the core material is a certain stiffness Insulation materials, such as rock wool, rigid foam, etc., in a dedicated automated production line composite bearing capacity of the structural plate, also known as "sandwich" board. Metal surface sandwich panel should be considered when the main technical indicators of metal surface sandwich board should be considered when using the main technical indicators of metal surface sandwich board should be considered when using the main technical indicators of metal surface sandwich board should be considered when the main Technical indicators :::: bonding performance, peel performance, bending load capacity, thermal conductivity, fire resistance, combustion performance. Double-sided color steel rigid polyurethane plate its bulk density of 35 ~ 40kg / m3, thermal conductivity: 0.018-0.023, low thermal conductivity, thermal performance.

- Q: Does the color steel sandwich panel plant require an environmental permit?

- (1) a copy of the application form for environmental management of the construction project; (2) the registration form of the proposed environmental impact of the project; (3) the project proposal and the relevant department approval document of the project proposal; (4) Topographic map, the map should be marked around the proposed project; (5) the proposed project to be approved by the local Environmental Protection Agency.

- Q: What are the key notes when buying a rock wool sandwich panel?

- There are four key factors: 1. Look at the use of construction: long-term construction or plant application of high quality (rock wool density is equal to 120kg / m3, the outer steel thickness is equal to 0.7mm, thickness of 100mm or more) of the rock wool sandwich panels, because the simple rock Cotton sandwich board after the installation of the surface easy to arch, bubble 2. Flatness: the requirements of the facade of the high demand, the use of mirror flat cotton wool sandwich panels, mirror flat cotton wool sandwich panels than the production of ripples difficult 3. Fire resistance: rock wool board production process should pay attention to the mouth and the mother of the filler, filled with rock wool board fire performance, filled with polyurethane and other materials, poor fire performance 4. Gongkou and the mother after the joint, the horizontal joints at the level of high and low error, high-quality quality rock wool board error is very small, low-end products will be interested in the horizontal slit to 10mm desalination level difference.

- Q: what is the specification of Alumni foil used in the sandwich panel(foam) as roofing?

- Alumni do not make good foil material........

- Q: Are thermocol roof insulation boards or thermocole sandwich concrete bricks durable?

- I typed in thermocol and this is what it gave me. Hope it helps. polystyrene (p?l'ēstī`rēn), widely used plastic plastic, any organic material with the ability to flow into a desired shape when heat and pressure are applied to it and to retain the shape when they are withdrawn. Polystyrene is a colorless, transparent thermoplastic that softens slightly above 100°C; (212°F;) and becomes a viscous liquid at around 185°C; (365°F;). It is resistant to acids, alkalies, oils, and alcohols. It is produced either as a solid or as a foamed plastic marketed under the trade name Styrofoam. Its many uses include electrical and thermal insulation, translucent window panels, storage-battery cases, and toilet articles

- Q: Do the closet with a sandwich board? Or with a MDF good?

- Or with sandwich panels, and now the market is a kind of better plate, called multi-layer solid wood or multi-layer plywood, the quality carry carry, and do the wardrobe is also very high Oh

Send your message to us

WBP Black Film Faced Plywood 15mm Marine Plywood

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords