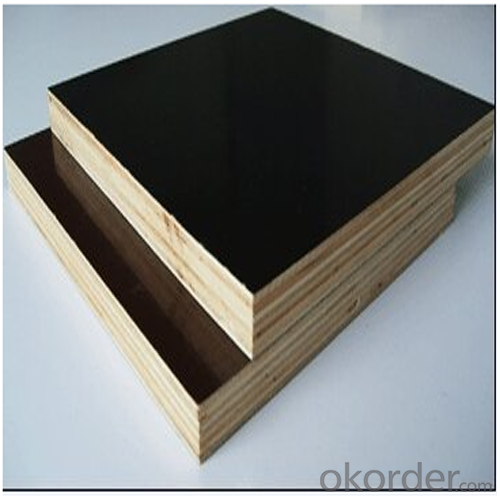

Poplar Core Film Faced Plywood with Good Quality and Competitive Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m³

- Supply Capability:

- 9000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details:

· Type: Plywoods

· Place of Origin: Shandong, China (Mainland)

· Usage: Outdoor

· Grade: First-Class

· Main Material: Poplar

· Formaldehyde Emission Standards: E2

· Plywood Type: Veneer Boards

· Veneer Board Surface Finishing: Double-Sided Decoration

· Veneer Board Surface Material: Birch

· Size: 915*1830,1220*2440,1220*2550mm

· Glue: MR,WBP,MELAMINE

· Main market: Europe, The Middle East, Africa/Latin America

· Thickness: 9-35mm

· Certification: ISO9001

Packaging & Delivery:

Packaging Details: | Inner packing: inside pallet is covered with 0.2mm plastic bag; Outer packing: by pallet, wrapped in carton, reinforced with iron belt, and seaworthy for shipping by sea |

Delivery Detail: | within 15days after receiving prepay or against origin L/C |

Product Specifications:

Film faced plywood

Size: 1220*2440,1250*2500

Core: Birch, poplar and hardwood

Glue: WBP, melamine, MR

Film: Brown and black film

FILM FACED PLYWOOD with good quality and competitive price

Product | black film faced plywood and brown film faced plywood |

Face and back | Okoume, bintangor, poplar, birch pine |

Core | Poplar, hardwood, birch or as your requests |

Thickness | 9-35mm |

Size | 1220*2440mm 1250x2500mm |

Glue | MR,WBP.MELAMINE |

color | black and brown |

Moisture | 6-14% |

Density | About 600kg/m3 |

Formaldehyde release | E0≤0.5mg/L E1≤1.5mg/L ≥E2≤5.0mg/L |

Bonding strength | ≥0.9mpa |

Packing | Inner with plastic bag, outside covered with |

Plywood at cartons, then steel tapes for strength | |

Transportation | 8plts/20GP,16plts/40GP,18plts/40HQ |

Payment | T/T L/C |

Min order | One 20GP |

Delivery time | within 15days after receiving prepay or against origin L/C |

Supply ability | 60*40HQ per month |

Certificate | ISO/CE |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, if needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Product Show:

- Q: Level sandwich panels are not 820 type

- In fact this is nothing, JXB is not the first letter of the word sandwich panels. 42-333-1000 This is the sandwich panel on the upper and lower color plate model. For example: YX28-205-820 pressure wave height of 28MM wave width 205MM effective width is 820mm a look at this model is 4 wave color plate JXB42-333-1000 can explain: sandwich board which up and down a plate of the color plate 42MM pitch 333 effective use of the width of 1000 This model can be seen is 3 wave pressure plate. Sandwich panels are made of upper and lower color plate glue (foam) combination. The composition of the bubble is different, the name is also different, there are rock wool with polyurethane and so on

- Q: Eps sandwich board and Caigang sandwich board is not two kinds of materials to the two of the price?

- Yes, EPS is glass steel surface, color steel sandwich board is color steel surface, EPS expensive, the difference is about 100 per meter

- Q: What is the acceptance criteria for rock wool sandwich panels?

- 1) upper and lower surface: the use of galvanized color steel plate, the thickness of 0.4-0.8mm. According to the specific requirements of customers, can also be used galvanized steel or galvanized steel plate. The steel plate is first molded by a molding machine and is compounded with the rock wool factory. ? 2) Yanmian core material: the use of density of 120kg / m yan rock block staggered laying, the fiber perpendicular to the sandwich plate on the upper and lower surfaces, and close contact to enrich the sandwich panel of the entire vertical and horizontal. The combination of rock wool and rock wool and the upper and lower steel plates through the high-strength foaming agent to form a whole, sophisticated production process to ensure that the high-density rockwool insulation and metal plate between the inner wall can produce poles Strong adhesion, so that the rock wool sandwich panel has a very good stiffness. ? Wujiang City Linxue purification Choi Board Co., Ltd. is the China Electronics Society Clean Technology Branch members. Commitment to various types of purification decoration, clean air-conditioning works, hydropower engineering facilities supporting the design, installation, commissioning through-train service.

- Q: What are the quality standards for color steel sandwich panels?

- Look at the weight of the foam board!

- Q: 100 thick rock wool sandwich panels (1.1 meters from the purlin) can do the roof? Floor thickness 0.8, panel thickness 1, so feasible?

- It is recommended to use pressure plate, flat or defective.

- Q: What are the varieties of foam sandwich panels? what is the price?

- Foam sandwich panel is made of OKorder Wang Teng Color Steel Co., Ltd. is made of advanced technology, foam sandwich panel Product performance: color plate thickness 0.2mm ~ 1.0mm Core thickness: 50mm ~ 250mm Effective height: 1000mm, 1200mm Applicable scope: workshop, office cabinet wall, steel structure exterior wall maintenance, decorative building materials, activities, office buildings and other fire rating: B3 (flame retardant: melting) moisture absorption: 3.9 (%) foam sandwich panels Features: It has a wide range of applications, especially for temporary facilities such as offices, warehouses and fences for construction sites. It is a wide range of applications, such as office buildings, warehouses, fences. And so on, but also reflects the modern construction site of civilized construction, especially in the rapid installation and put into use, can be equipped with removable, material turnover index, there are obvious advantages, a substantial reduction in temporary construction site costs, Is indispensable for new lightweight building materials.

- Q: 11.44 m wide need sandwich panels how many blocks

- .8 × 0.64 square meters Need the number of bricks = Living room area ÷ a tile area = 32 ÷ 0, floor tile length = 8 cents = 0, width = 4 meters, Get a piece of tiles = Side length × side length = 0.8 = 0.8 m, The area of the living room = Long × wide = 8 × 4 = 32 square meters And covered with square tiles: known living room length = 8 meters: a total of 50 tiles = 50 blocks

- Q: The steel roof and the sandwich panel are waterproof

- The two are actually the same class of things, sandwich panels only the color plate and insulation layer together, the installation more convenient. And the pressure steel roof need to lay another insulation layer and the roof. For both, the weak links of water are between the plates. In the actual project, the seam of the steel plate roof can be made in many forms, some of the overlapping form of waterproof performance is very good, and the common sandwich board roof shape is relatively simple, so the waterproof performance is also worse.

- Q: Does the country 's steel market have sandwich panels?

- Sandwich panel products are composed of two layers of metal panels (or other material panels) and directly in the middle of the panel foam, mature molding of the composition of the polymer core insulation. These sandwich panels are easy to install, lightweight and efficient. Filling system is also used to close the molecular structure, you can put an end to the condensation of water vapor. The forming of the outer steel sheet takes into account the structural and strength requirements, and takes into account the appearance, the inner layer is formed into a flat plate to suit various needs. Guoqiang steel market with sandwich panels.

Send your message to us

Poplar Core Film Faced Plywood with Good Quality and Competitive Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m³

- Supply Capability:

- 9000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords