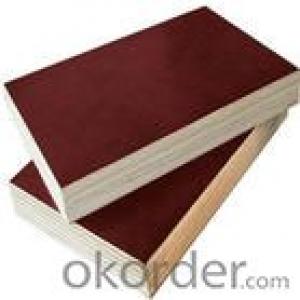

15mm Thickness Film Faced Plywood with Brown Color Film

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

15mm Thickness Film Faced Plywood with Brown Color Film

Product Description:

· Type: Film Faced Plywood

· Material: Wood

· Wood Style: Panel

· Panel Type: Plywood

· Use: Indoor

· Place of Origin: China (Mainland)

· Model Number: 1220x2440mm

Plywood is a wood product manufactured out of many sheets of veneer, or plies. And plywood is pressed together and glued, with their grains going in opposite directions. It is also referred to as an “engineered wood”, because it is made from the compound wooden materials, and formed various forms go through thousands of years.

Packaging & Delivery:

1. Packaging Details: inner packing:0.20mm plastic bag; outer packing: pallets are covered with plywood or carton and then steel for strength

2. Delivery Detail: within 15 days after receiving the deposit

Product Specification:

Detailed Product Description | ||

Features | Face/back | melamine /veneer/pvc/hpl/ev (As you required) |

Glue | E1 or E2 ... (As you please) | |

Size | 1220*2440mm or 1830*2440mm | |

Thickness | 2.0mm~35mm | |

Core | poplar, combi etc. | |

Moisture | normal, moisture-proof, water-proof, eco-friendly | |

Payment & Shipping | MOQ | 1*20' container (negotiable) |

Port | Qingdao | |

Packing details | Inter packing: 0.20mm plastic bag Outer packing: pallets are covered with plywood or carton and then steel for strength | |

Delivery time | Within 15~20 days after 30% deposit or L/C | |

Payment terms | L/C,T/T | |

Supply ability | 50*40' HQ per Month | |

Advantages | Guarantee of 2 years | |

Competitive price | ||

ECO- friendly—— E1 grade, CARB P2 certificated | ||

High quality and excellent workmanship | ||

Company Info:

OKorder.com is an online building materials trading platform funded by CNBM (listed 267th on Fortune Global 2014) and is operated by CNBM International. CNBM International has more than 20 years trading experience and has established close business relationships with clients from over 160 countries.

As of the end of 2000, CNBM has 492 member companies under management around the world, of which 5 were A-share listed holding companies and 2 were H-share listed. CNBM has total assets exceeded RMB 110 billion, and more than 100,000 employees.

CNBM is the largest comprehensive building material industrial group in China that integrates scientific research, manufacturing and logistics into one entity.

OKorder.com is an online building materials trading platform funded by CNBM (listed 267th on Fortune Global 2014) and is operated by CNBM International. CNBM International has more than 20 years trading experience and has established close business relationships with clients from over 160 countries.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, if needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Product Show:

- Q: Solid wood sandwich board how much money a piece

- No-name card (no license) 50 ~ ~ 60 yuan a brand, but the quality of the general 70 ~ ~ 90 yuan a brand, brand products (real 3A) more than 120 yuan each! Hope to help you, please adopt

- Q: Flammable and toxic "" "", how long life?

- Some polyurethane foam, some polystyrene foam. Non-toxic Flammable or not depends on the production of the time there is no plus flame retardant, the general GB is required B1 level, and non-flammable. Life expectancy, three to five years can certainly use = =

- Q: Sandwich board ceiling how to build? What's the utility?

- Hello, as far as I know: the general price of a square in twenty or thirty dollars or so look. Sandwich panels are widely used in industrial non-load-bearing walls and civil buildings, roofs, ceilings and housing wall panels, machinery, electronics, chemical industry, insulation, , Medicine, biology, food, health and other clean room partition, ceiling, etc. for a single combination of Caigang sandwich panels. The sandwich plate molded part is a cured composition of a metal plate (or other material panel) made of two layers and a polymer formed by foaming directly in the middle of the panel and forming the insulating core. The above prices are network reference, the specific price to the actual purchase. Hope to help you

- Q: I don't want to gain weight, so is this a healthy one: pita bread, organic peanut butter, and organic grape jelly.

- you are better off using whole grain bread, lowfat peanut butter, and thinly sliced strawberries

- Q: Rock wool sandwich board standards which

- Rock wool core material: the use of density of 120kg / m? rock block staggered laying, the fiber perpendicular to the sandwich plate on the upper and lower surfaces, and close contact to enrich the sandwich panel of the entire vertical and horizontal. The combination of rock wool and rock wool and the upper and lower steel plates through the high-strength foaming agent to form a whole, sophisticated production process to ensure that the high-density rockwool insulation and metal plate between the inner wall can produce poles Strong adhesion, so that the rock wool sandwich panel has a very good stiffness.

- Q: Sandwich board formaldehyde excessive fine how much

- You do not want to fine, and hurry up and then do good relations with the department, otherwise you do not exceed the standard will be fined.

- Q: Color steel polyurethane sandwich panels can do the paint room cut off you

- Can be cut off, in the construction area with more, and the sound insulation and insulation effects are very good. Polyurethane material has excellent water resistance, steam barrier performance, material does not contain water, water absorption is very low, can well block the water and water vapor infiltration, the wall to maintain a good, stable adiabatic situation, is other insulation materials Difficult to achieve.

- Q: What is the difference between a steel structure installation sandwich panel and a field composite board approach?

- Color steel, also known as: color pressure tile, is the use of color coated steel plate, the cold bending into a variety of wave-type pressure plate, it applies to industrial and civil construction, warehouses, special buildings, large span steel housing Roof, wall and interior and exterior decoration, with light, high strength, rich color, convenient construction, earthquake, fire, rain, long life, free.

- Q: Steel structure, activities, such as sandwich panels board generally what kind of self-tapping screws fixed ah?

- Self-tapping screw, the English name Self-tapping Screw is a metal or non-metallic materials in the pre-drilling hole in the self-drilling with a female thread with a threaded fastener. Self-tapping screws are used for connection between thin metal plates (steel plates, saw boards, etc.). When connecting, first thread the bottom of the connector, and then screw the tapping screw into the threaded bottom hole of the connected part. As the tapping screw thread surface has a high hardness (≥ 45HRC), can be connected to the threaded bottom hole in the internal thread, thus forming a connection.

- Q: Will the rock wool sandwich board which manufacturers better?

- I know, you can consider Zhejiang Bo Ya building materials, production Yanmian sandwich panels, all kinds of sandwich panels,

Send your message to us

15mm Thickness Film Faced Plywood with Brown Color Film

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords