Fiberglass Mesh China - Polyester Warp-Knitted Geogrid A Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

The specification of our products:

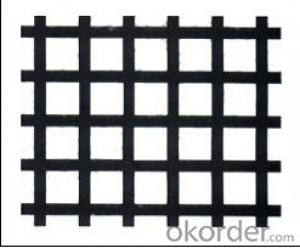

high stength polyester fiber warp-knitted geogridis made of high strength polyester fiber. The crossing of the warps and the wefts is notflexible, joint probably, make full use of its mechanics performance. It has the following performance: High strength, lowstretch, tearresistant, wearproof, anticorrosive, light, joint with clay and fine stones easily and probably, improve the whole body performance and the capacity of load.

The function fo the product:

Reinforce of the soft foundation, the steel reinforcement of the road dykes slopes, the isolation walls and the surface of the roads and bridges.

Applied area:

Use for the foundations of the high class roads, railways.

Reinforce the slopes of the river banks and roads.

Reinforce all the foundations.

1. Tensilestrength: PET20-20, 40-40, 80-80, 100-100, 120-120, 60-30, 80-30, 120-30, 200-30, 300-30kn/m

2. Break elongation: ≤13%

3. Mesh Size: 12.7x12.7mm, 25.4x25.4mm or others

4. Width: 1-6m

5. Length: 50m or 100m or others

6. Coated by PVC

- Q: Why does the construction sector have no supervision on the use of fiberglass mesh?

- External thermal insulation needs a large amount of fiberglass mesh.

- Q: The difference between glass wool and mineral wool insulation

- Glass wool than low density rock wool, slag ball less content, low thermal conductivity, long service life, high toughness fiber, but the maximum use temperature of high rock wool up to 600 degrees Celsius, glass wool is only 260 degrees celsius.

- Q: I am a worker using glass silk to weave mesh. What harm does long-term work do to body?

- Glass silk, or glass fiber, is nontoxic. But once inhaling small fiber powder, you will get pneumosilicosis that is the special occupational disease in silicate industries like glass, cement and porcelain. If you are engeged in the above indtries, you should wear a dust mask and have periodic physical examinations; enterprises should take strict safegaurd measures according to related institutions.

- Q: Exterior wall heat preservation steel wire mesh or mesh cloth good?

- Glass fiber mesh cloth with alkali resistant fiberglass mesh, it uses alkali free glass fiber yarn (the main ingredient is silicate, good chemical stability) by special cutter structure after weaving, anti alkali, heat setting treatment such as reinforcing agent, has good alkali resistance, flexibility and high resistance to warp pull, is widely used in the inside and outside the building wall insulation, waterproof and anti crack.

- Q: How to use gridding cloth tape, namely glass fiber self adhesive tape?

- 1. Keep the wall clean and dry. 2. Paste and press the tape on the crack. 3. Confirm that the gap has been covered with tape, and then cut the needless tape and paint with mortar. 4. Allow it to dry naturally, then polish gently. 5. Fill enough paint in and make its surface smooth. 6. Cut the leak-out tape. Then, check if all the cracks have been properly patched, and decorate the crack with subtle composite material to make it look clean and new.

- Q: Does alkali resistant glass fiber gridding cloth belong to energy-saving material?

- Alkali-resistant glass fiber gridding cloth is a kind of reinforcing material of external wall thermal insulation layer and is mainly used for improving the mechanical strength of the surface, ensure the resistance of continuity of decoration surface layer, scattering the shrinkage stress and thermal stress to avoid stress concentration, crack resistance caused by temperature and humidity change and accidental impact. Therefore, the alkali resisting glass fiber gridding cloth plays an important function and role in outer insulation system, so good glass fiber gridding cloth also is an important part of external thermal insulation system.

- Q: With what to cut fiberglass mesh?

- The width of fiberglass mesh is fixed in the production process, then it will become rolls. Manufacturers sell products of different widths, so you just need to purchase meshes according to the procurement requirements.. If you do not need special width, you can customize it at the factory. If it has to be processed into rolls of different width, hand saw is suggested because the temerature generated by rapid electric speed won't be lost in a short time. But the high temperature will melt glass, increase resistance, damage saw web, and even burn the circuit.

- Q: does the anti-cracking net between the different matrixof the interior wall plastering can use the glass?fiber alkali resistant mesh? the steel mesh are hanging between the contacts.

- Plastering generally use galvanized wire mesh, because it is relatively strong. the price is similar.

- Q: What are the characteristics of the external insulation materials Mesh?

- The external wall thermal insulation Mesh (the glass fiber mesh) is with the raw material of alkali-free glass fiber, and with the glass fiber Mesh as base material, becoming a new alkali product by the coatingacrylic?acid method. The product has the characteristics of stable structure, high strength, good acid and alkali resistance, anti-corrosion, and anti-cracking ability. It has a best effect of enhancement and easy for construction. It is mainly used in cement, gypsum, walls, buildings and other structures inside and outside. It can also be used to anti-cracking, and being a new building materials of the external wall building engineering. Mesh(2 pieces) The external wall thermal insulation Mesh (the glass fiber mesh) is with the raw material of alkali-free glass fiber, and with the glass fiber Mesh as base material, then making by the acrylate copolymerization glue soluting. It has the characteristics of lightweight, high strength, temperature resistance, alkali resistance, water proofing, anti-corrosion, anti-chapping, and stable size. It can effectively avoid the crack brought by the tension contraction of the plastering layer and the external force. The thin Mesh is often used for the refurbishment of wall and the thermal insulation of the interior wall. Mesh: 5mm * 5mm, 4mm * 4mm gram weight: 80g --- 165g / m Width: 1000mm ---- 2000mm Length: 50m-300m or according to the requirements of the customer. The construction requirements of the Mesh. 1. The first floor of the word building, the doors and windows, decorative sewing, the internal and external corners, all these places should be taken to add a layer of alkali-resistant mesh cloth and wipped a cracking mortar. 2. The lap of the ordinary alkali-resistant mesh should not be less than 100mm, and the reinforced alkali-resistant mesh cloth should only be butted joint but not lapped.

- Q: Is glass fiber harmful to people?

- The extent of skin damage depends on fiber diameter and surface roughness. It is now accepted that fiber diameter exceeds 5 mu m, which has a significant stimulating effect. A small number of people exposed to glass fiber and rock wool have skin allergies, but so far they have not been proved to be allergens. Eye and mucous membrane endanger: the worker that contacts glass fiber and so on can suffer conjunctivitis and keratitis, serious person can see the cornea is cloudy and local abscess. From the patient's eyes, a fiber less than 3 m in diameter can be developed. Pathological examination of the eyeball showed that the proliferation of corneal epithelial cells and the increase of mucin content in the conjunctiva showed mechanical stimulation. Similar pathological changes were confirmed by animal experiments. Experiments show that asbestos substitutes can produce toxicity and carcinogenicity similar to that of asbestos when the size and length of fibers are similar. Asbestos Substitutes dust has the effect of certain biological damage to human and animal, its biological activity and pathological effect is not asbestos, but as the mass production and use of Asbestos Substitutes, the harm can not be ignored.

Send your message to us

Fiberglass Mesh China - Polyester Warp-Knitted Geogrid A Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords