Vertical, single-stage submersible motor pump Amarex N

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 1 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Design

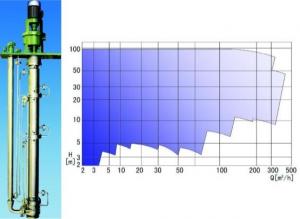

Vertical, single-stage submersible motor pump, for wet installation, stationary and transportable design. Amarex N pumps are floodable, single-stage, single-entry close-coupled pump sets which are not self-priming. Explosion-proof design available (ATEX, FM, CSA).

Applications

Handling of all types of waste water, especially untreated sewage containing long fibres and solid substances, fluids containing gas/air, as well as raw, activated and digested sludge; Removing waste water from flooded rooms or surfaces.

Overview of technical data

| Type of installation | Close- coupled |

| Maximum drive rating | 4, 20 kW |

| Type of bearing | Rolling element bearings |

| Drive frequency | 50 Hz / 60 Hz |

| Maximum flow rate | 190 m³/h |

| Casing material (EN standard) | JL 1040 |

| Casing material | Cast iron |

| Drive voltage | High voltage |

| Pump set location | Wet well |

| Explosion protection | EX- SCHUTZ EEX D IIB;ATEX 100A |

| Free passage | 100 mm |

| Main applications | Waste water / sewage;Industry and process engineering;Building services |

| Type of installation | Stationary; Transportable |

| Type of lubrication | Grease lubrication |

| Type of drive | Electric motor |

| Installation position | Vertical |

| Shaft material (EN standard) | 1. 4021 |

| Type of coupling | None |

| Shaft seal type | Mechanical seal |

| Drive | Electric motor |

| Maximum head | 49, 00 m |

| Connection to power supply | 400 V, 3~ |

- Q: A residential building with a floor height of 11 stories and a roof height of 33 meters. The height of the water tank is 37.7 meters. The basement is -3.3 meters, only set fire hydrant, fire pump only consider the indoor fire water, fire flow should be 10l/s. Now select a fire pump, concrete should be much traffic, big head, flow determine how? How to determine the head, I hope to say some more detailed, thank you, and there is to explain this question, why is the fire pump lift 120?. Thank you

- According to the water quantity form fire flow water supply system fire safety in high-rise building fire hydrant pump lift is 10L/s, accurate algorithm is to say after a simple calculation with each indoor hydrant flow is two 5L/s bolt so to get the most unfavorable point for the calculation unit to calculate the minimum requirements, with the most unfavorable point suppository pressure specifications 0.07MPa, partial loss of the most unfavorable line and the line (according to the equivalent length) and loss (according to the material resistance coefficient), and finally the pump head loss of gravity difference. But we just calculate the construction elevation difference multiplied by 110% to 120% to determine the head {there is a need to know is: conversion head (m), (kg) and MPa kg 1MPa=10 kg = 100m is the vertical water column on unit area pressure conversion

- Q: The suction pump has a nominal suction range of 30 metersHow deep can a well be sucked?Well, sixteen meters,

- That is impossible. The suction height of the pump is caused by the centrifugal force of the vacuum. The water is sucked into the vacuum

- Q: The water tank of the fish tank does not air out and only has the water outlet

- The water pump is cut off, the intake pipe is drawn out, and the water in the air pipe is blown out, then the water pump is put on the surface of the water, and the air inlet pipe is inserted on the surface of the water pipe, and then the water pump is put back into the water, and the water pump is electrified. Try again several times at a time. It should be effective.

- Q: The difference between diaphragm pumps, vacuum pumps and centrifugal pumps

- The diaphragm works by changing the size of the diaphragm. When the cup is covered with an eraser and the edge is airtight, then pressing the rubber or pulling the rubber outward will make the pressure in the cup increase or decrease. Use this principle, in the pressure of an hour from a hole suction medium, when the pressure is large, from another hole extrusion medium, so as to achieve the purpose of conveying.

- Q: Shielding pump is the main drawback of electricity? How much does it cost more than an ordinary centrifugal pump? Is there any noise in the running of the canned pump? How much is it lower than the noise of the common centrifugal pump?

- The graphite bearing lubrication medium, make the operation less noise and manual, reduce maintenance costs; in recent years, bearing material added with silicon carbide SIC, super hard, life is better than that of graphite bearing.The vertical structure can be installed on the pipeline like a valve, the installation is convenient and quick, and the motor and the impeller can be drawn out only when the utility model is used, and the pipeline is not needed to be removed.The utility model can be installed and run with a shock absorber or a damping pad, so that the pump is less noisy at running time.

- Q: What is the function of the heating pump system for the water pump design?

- As the feed water temperature is higher, in the case of non warm pump start, will make the pump body is subject to greater thermal impact; in addition, the flow components with the pump contact heating fast, not contact with water directly heating slowly. This expansion due to uneven speed, it will inevitably produce thermal stress, deformation of the pump body, sealing surface, the joint surface is lax and leaking phenomenon. Therefore, the warm water pump system is designed for the water pump.

- Q: What is the pumping property of concrete?

- Pumping capacity means that fresh concrete can be transported by concrete pump, and concrete construction can be carried out with high efficiency. 'pumping' is a qualitative statement

- Q: Water pump spoon pipe for power plantWhich hero can tell me what is the water pump spoon tube ah? And its role

- By adjusting the amount of oil entering into the hydraulic coupler, the torque of the hydraulic coupler can be controlled

- Q: How many pumps does the 80cm tank use?

- For example, you are 80 cm tank, assuming you are 40 cm wide, the water surface is also 40 cm, then the final count by 80X40X40=128000 cubic centimeter, that is, 128000 ml.

- Q: What flowmeter is installed after the pneumatic diaphragm pump?

- The pressure decreases, the diaphragm moves slowly, and the flow decreases.This is not particularly accurate, because the diaphragm is not a metering pump, but the approximate flow can still be controlled.

Send your message to us

Vertical, single-stage submersible motor pump Amarex N

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 1 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords