Fiberglass Fabrics - e-glass stitich combo mat- tlx top quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 3000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

E-glass stitched combo mat consists of two or more layers of fiberglass roving which are stitch-bonded.One layer of rovings and different layers of roving can be oriented differently and have different liner density.The roving specification,number of roving layers,mat width and roll diameter can be customized as per requirement.

Application:

The product is most widely used in hand lay-up process and also can be used in filament winding. compression molding and continuous laminating processes. The typical end products including various panels, boats,bath equipment automotive parts and cooling towers

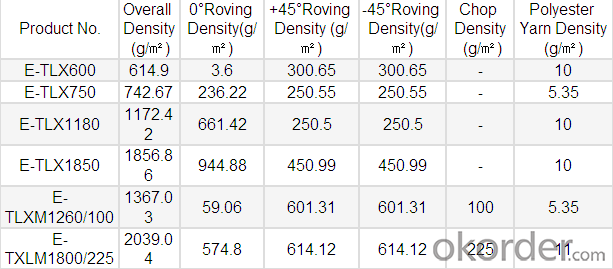

Specifications:

Packaging:

It’s wound into a paper tube( inside diameter about 90mm, outside diameter about 265mm).the mat roll is wrapped with plastic film,and then packed into cardboard box or wrapped with paper.the rolls can be stacked horizontally.the rolls can be palletized or loaded into container.

FAQ:

1.What is the delivery time ?

15days after receiving the deposit

2.Are you a trading company or factory.

We are factory,and we have more than 10 years of experience.

- Q: Is fiberglass fabric resistant to oil and grease?

- Yes, fiberglass fabric is generally resistant to oil and grease. Fiberglass has excellent chemical resistance properties, making it highly resistant to a wide range of oils and greases. This resistance is due to the non-reactive nature of fiberglass, which prevents the fabric from being degraded or damaged by contact with oil and grease. Additionally, fiberglass fabric is also resistant to many other chemicals, including acids, alkalis, and solvents, making it a versatile material in various industries where resistance to oil and grease is required. However, it is important to note that the level of resistance may vary depending on the specific type and quality of fiberglass fabric used. It is always recommended to consult the manufacturer or supplier for specific information on the resistance capabilities of the fiberglass fabric in question.

- Q: What are the different thicknesses of fiberglass fabric available?

- A variety of thicknesses of fiberglass fabric are offered to meet different needs and uses. Fiberglass fabric is typically measured in ounces per square yard (oz/yd^2). The most commonly used thicknesses range from 4 oz/yd^2 to 10 oz/yd^2, with increments of 2 oz/yd^2. For applications requiring a thin and flexible material, such as repairs on small boats or automotive parts, 4 oz/yd^2 fiberglass fabric is commonly chosen as it is relatively lightweight. A medium-weight option, 6 oz/yd^2 fiberglass fabric, provides better strength and durability compared to the 4 oz/yd^2 option. It is often used for general repairs, reinforcing weak areas, or constructing lightweight structures. For increased strength and rigidity, the 8 oz/yd^2 fiberglass fabric is a heavier option. It is commonly used for more demanding applications like reinforcing large structural components or manufacturing composite parts. When maximum strength and durability are required, the thickest commonly available option, 10 oz/yd^2 fiberglass fabric, is chosen. It is often used for industrial purposes like reinforcing concrete structures or manufacturing high-performance composite materials. Aside from these common thicknesses, there are specialty fiberglass fabrics available that can be much thicker or thinner depending on the specific application. It is crucial to select the appropriate thickness of fiberglass fabric based on the intended use to ensure optimal performance and desired outcomes.

- Q: Are fiberglass fabrics resistant to solvents or cleaning agents?

- Yes, fiberglass fabrics are generally resistant to solvents or cleaning agents. Fiberglass is a synthetic material made from fine fibers of glass, which provides it with excellent chemical resistance. It can withstand exposure to a wide range of solvents, cleaning agents, and chemicals without deteriorating or losing its structural integrity. This makes fiberglass fabrics an ideal choice for various applications where resistance to solvents or cleaning agents is required, such as in industrial settings, automotive components, insulation materials, and protective clothing. However, it is always recommended to check the specific chemical compatibility of the fiberglass fabric with the solvent or cleaning agent in question, as some highly aggressive chemicals may still have an impact on its performance.

- Q: Can fiberglass fabric be used for making gloves?

- Yes, fiberglass fabric can be used for making gloves. Fiberglass fabric is a strong and durable material that provides excellent resistance to heat and fire. It is often used in applications where high temperature protection is required, such as in the manufacturing industry or in situations where working with hot objects is involved. The fiberglass fabric can be woven or knitted into gloves, providing a protective barrier for the hands against heat, sparks, and flames. However, it is important to note that fiberglass can cause skin irritation and itchiness, so proper precautions and safety measures should be taken when using fiberglass fabric gloves.

- Q: What are the different fiberglass fabric coatings for chemical resistance?

- There are several different fiberglass fabric coatings available for chemical resistance, including neoprene, polyurethane, vinyl, and silicone. These coatings provide a protective barrier against a wide range of chemicals, ensuring the durability and longevity of the fiberglass fabric in various applications.

- Q: How does fiberglass fabric perform in terms of fire resistance?

- Fiberglass fabric has excellent fire resistance properties. It is inherently non-combustible and does not contribute to the spread of fire. It has a high melting point, which allows it to withstand high temperatures without catching fire or melting. Additionally, fiberglass fabric does not release toxic fumes when exposed to flames, making it a safe choice in fire-prone environments.

- Q: How is fiberglass fabric used in the automotive industry?

- Due to its unique properties, fiberglass fabric finds extensive use in the automotive industry for a variety of purposes. One of the primary applications of fiberglass fabric in this sector involves the production of car parts such as body panels, hoods, and spoilers. The choice of fiberglass fabric for these purposes is driven by its lightweight, strong, and durable nature. This material boasts an impressive strength-to-weight ratio, enabling it to provide robustness to car parts without adding unnecessary weight. This aspect is crucial in enhancing fuel efficiency and overall vehicle performance. Furthermore, fiberglass fabric is also employed in the automotive industry for insulation purposes. It is commonly utilized to insulate engine components, including exhaust systems and heat shields, safeguarding surrounding parts against excessive heat. The remarkable temperature resistance of fiberglass fabric renders it an ideal option for these applications. Moreover, fiberglass fabric contributes significantly to the manufacturing of automotive interiors. It is frequently utilized in upholstery, door panels, headliners, and trunk liners. The fabric's exceptional flexibility allows it to conform effortlessly to various shapes and contours of the car interior. Additionally, it exhibits resistance to stains, chemicals, and fading, ensuring a long-lasting and visually appealing interior finish. Additionally, fiberglass fabric serves as a reinforcement material in the automotive industry. It is often incorporated as a layer in the production of composite materials used for manufacturing car parts. By combining fiberglass fabric with resins or other materials, manufacturers can create robust and rigid components capable of withstanding impacts, vibrations, and other external forces. Overall, fiberglass fabric plays a crucial role in the automotive industry, offering lightweight, durable, and heat-resistant solutions for diverse applications. Its versatility and exceptional properties make it an ideal material for manufacturing car parts, insulation, interiors, and reinforcement, thereby contributing to the efficiency, safety, and overall quality of vehicles.

- Q: Are fiberglass fabrics resistant to shrinkage or stretching?

- Fiberglass fabrics possess remarkable resistance against shrinkage and stretching, owing to the inherent qualities of fiberglass such as its impressive tensile strength and minimal elasticity. As a result, these fabrics prove highly resilient to both shrinkage and stretching, making them ideal for situations where dimensional stability is crucial. This includes their application in the production of industrial products, insulation materials, and composite materials. Moreover, due to their durability and resistance against shrinkage and stretching, fiberglass fabrics are well-suited for usage in high-temperature environments and adverse conditions. In conclusion, fiberglass fabrics provide outstanding stability and retain their shape and size even when subjected to diverse external forces.

- Q: How is fiberglass fabric used in the production of sports helmets?

- Fiberglass fabric is commonly used in the production of sports helmets due to its unique properties that make it an ideal material for this purpose. Firstly, fiberglass fabric is known for its strength and durability. It provides excellent impact resistance, which is crucial for protecting the head during sports activities where collisions and falls are common. The production process involves several steps. The fiberglass fabric is first layered and molded into the desired helmet shape using a combination of heat and pressure. This allows the fabric to conform to the specific contours and curves required for a comfortable and secure fit. Furthermore, fiberglass fabric is lightweight, making it an excellent choice for sports helmets. It does not add unnecessary weight to the user's head, ensuring comfort and reducing fatigue during prolonged use. Additionally, the lightweight nature of fiberglass fabric allows for greater maneuverability and agility, which is especially important in fast-paced sports. Another significant advantage of using fiberglass fabric in sports helmets is its resistance to water and moisture. This property ensures that the helmet remains intact and functional even in wet conditions, such as during water sports or heavy sweating. Moreover, fiberglass fabric is resistant to UV radiation, preventing degradation and maintaining the helmet's structural integrity over time. Lastly, fiberglass fabric offers opportunities for customization and design flexibility. It can be easily combined with other materials or coatings to enhance specific features of the helmet, such as adding an extra layer of protection or improving its aerodynamics. In summary, fiberglass fabric is an essential component in the production of sports helmets due to its strength, durability, lightweight nature, resistance to water and UV radiation, and design flexibility. It plays a crucial role in ensuring the safety and comfort of athletes participating in various sports activities.

- Q: What are the different fiberglass fabric finishes for water resistance?

- Water resistance can be achieved through various finishes on fiberglass fabric. One commonly used finish is silicone, which forms a waterproof barrier on the fabric surface. This type of fiberglass fabric is highly resistant to water and finds applications in outdoor covers, tents, and boat sails. Polyurethane is another finish that creates a water-resistant coating on the fabric. It is commonly used in rainwear, backpacks, and other outdoor gear where water resistance is crucial. Fluoropolymer finishes, such as PTFE or Teflon, provide excellent water repellency. Fiberglass fabric with a fluoropolymer finish is often used in awnings, umbrellas, and outdoor furniture covers, where water needs to bead up and roll off the surface. Acrylic finishes can also enhance water resistance on fiberglass fabric. Acrylic-coated fiberglass fabric is commonly used in marine applications, such as boat covers and biminis, as it offers good waterproofing while maintaining breathability. It's important to note that while these finishes offer water resistance, they may not provide complete waterproofing in cases of prolonged or heavy rain. In such situations, additional measures like seam sealing or using a waterproof membrane may be necessary for complete protection against water penetration.

Send your message to us

Fiberglass Fabrics - e-glass stitich combo mat- tlx top quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 3000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords