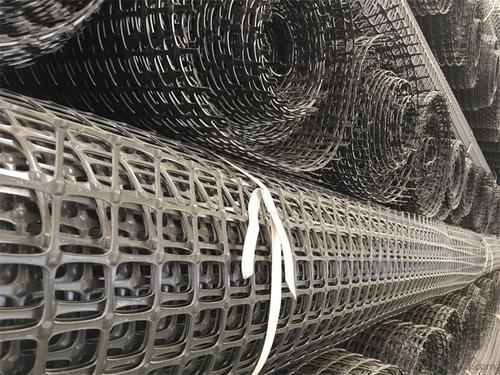

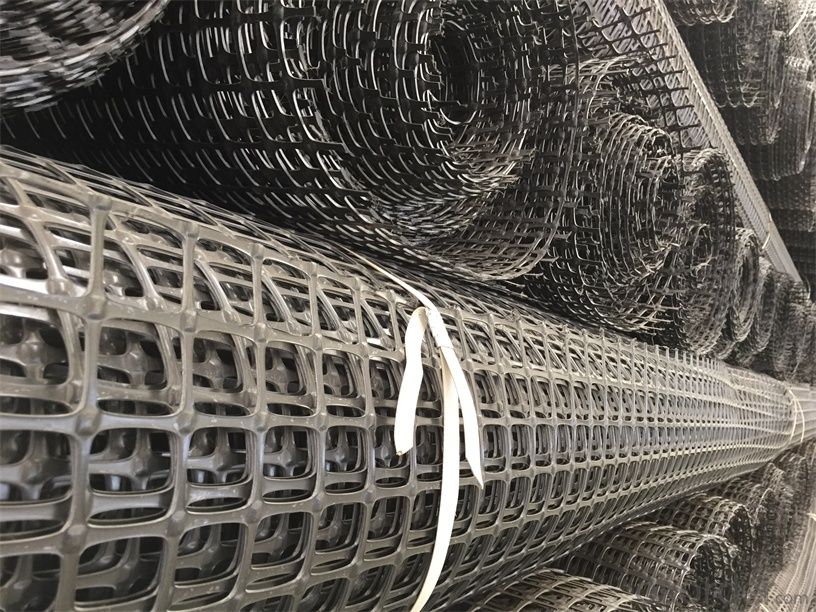

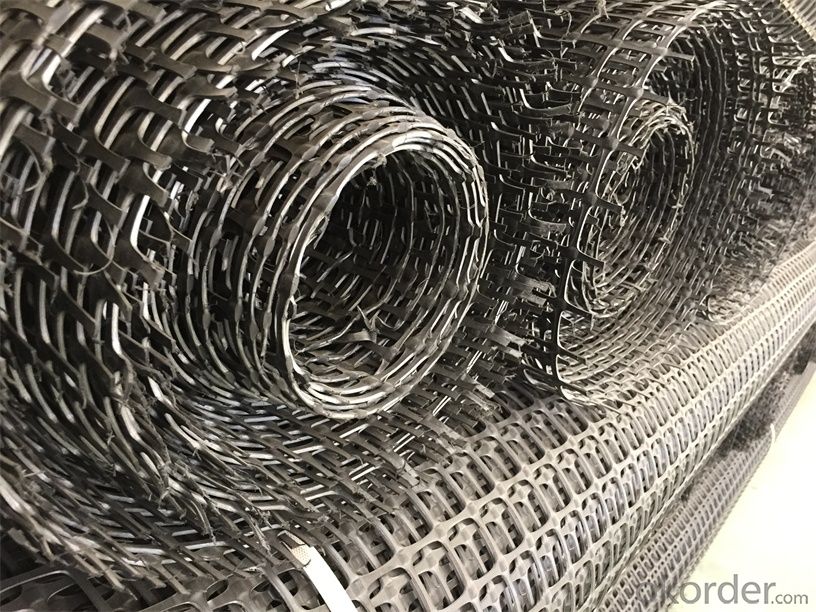

Vegetated Geogrids - Bitumen Coated Fiberglass Geogrid with High Tensile Strength

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid Introduction:

Fiberglass geogrid is a kind of planar mesh material using alkali-free fiberglass yarn as base body and then coated with high quality modified asphalt. It is warp knitted with oriental structure which gives full play of yarn strength and improves its mechanical property to make the product high tensile, tearing and creep-resistant. Moreover, the composite property of coating with asphalt makes full protection of the fiberglass matrix and greatly improves its wear and shear resistance. All the advantageous functions make the product have a good performance in pavement strengthening, track cracking and solving difficulties of strengthening the bituminous pavement.

Fiberglass Geogrid Features:

1. Light weight, high tensile strength, high modulus, low elongation and good toughness.

2. Corrosion resistance, no long-term creep, long life span.

3. Good physical and chemical stability and good thermal stability.

4. Resistant to fatigue cracking, high-temperature track and low temperature shrinkage cracking.

5. Delaying and decreasing crack reflection.

Specifications | PET20-20 | PET30-30 | PET40-40 | PET50-50 | PET80-80 | PET100-100 | PET120-120 |

Elongation(%) | 10%~15% | ||||||

Vert Tensile strength(KN/m) | 20 | 30 | 40 | 50 | 80 | 100 | 120 |

Horiz Tensile strength(KN/m) | 20 | 30 | 40 | 50 | 80 | 100 | 120 |

Grid(mm) | 12.5×12.5 20×20 24.5×24.5 | ||||||

Width(m) | 1—6 | ||||||

Fiberglass Geogrid Application:

1. Road surface asphalt overlay construction engineering; Asphalt layers

reinforcement.

2. Converting old cement concrete road into composite road; Restraining

reflection cracking caused by block shrinkage.

3. Road extension; Preventing and controlling the cracking caused by new

and old combination and uneven settlement.

4. Treatment of the conjunction between tunnel and bridge or foundation.

Packaging & Shipping:

FAQ:

1. How to order your geogrid ?

a) Tensile strength in warp & weft direction

b) Grid size

c) Roll Width and length

d) Quantity

2. What is the Payment term?

a) TT

b) LC AT SIGHT

c) cash

d) 30% contact value as deposit ,the blance 70% be paid after received the copy of bl .

3. Delivery time

a) 19-25 days after received your depsit .

4. What is MQQ ?

a) 2500 m2 as MQQ , we can also produce sample for you .

Welcome to send your inquiry to us, and if you have any question, we can also help you.

- Q: Are geogrids suitable for use in cold climates?

- Yes, geogrids are suitable for use in cold climates. Geogrids are designed to withstand extreme weather conditions, including cold temperatures. They are made from materials that can resist freezing and maintain their structural integrity in cold environments. Additionally, geogrids are used for reinforcement and stabilization purposes in civil engineering projects, such as roads and retaining walls, in various climates worldwide, including cold regions.

- Q: Can geogrids be used in underwater applications?

- Yes, geogrids can be used in underwater applications. They are often employed in marine construction projects, such as offshore breakwaters, submerged revetments, and coastal protection systems. Geogrids are designed to withstand the harsh conditions of underwater environments and provide stability to soil or fill materials, preventing erosion and improving the overall performance of underwater structures.

- Q: How do geogrids help in reducing the risk of soil erosion?

- Geogrids help in reducing the risk of soil erosion by providing reinforcement and stabilization to the soil. They are typically made of high-strength materials like polyester or polypropylene, which are resistant to degradation and can withstand heavy loads. When placed in soil, geogrids create a network of interconnected cells that increase the soil's resistance to erosion caused by water flow or wind. This reinforcement prevents the soil particles from being displaced, maintaining the integrity of the slope or embankment. Geogrids also improve soil drainage, allowing excess water to pass through and reducing the likelihood of erosion. Overall, geogrids act as a physical barrier against erosion forces, enhancing the stability and longevity of soil structures.

- Q: How does the steel plastic geogrid stretch? Where do you have a special fixture to sell? What is the best thing to use?

- High strength, small deformation; 2 small creep; 3 corrosion resistance, long service life: steel plastic geogrid with plastic material as a protective layer, which is supplemented with a variety of additives in aging resistance, oxidation resistance, corrosion resistance to acid and alkali, salt and other harsh environment. Therefore, the steel plastic geogrid can meet the needs of more than 100 years of permanent engineering applications, and excellent performance, good dimensional stability. 4 convenient construction, short cycle, low cost, steel plastic geogrid laying, lapping, easy positioning and smooth, to avoid overlap, can effectively shorten the construction period, save the project cost 10%-50%. Engineering applications: highway, railway, bridge, road, pier, dam, slag field, such as soft soil foundation reinforcement, retaining wall and pavement crack resistance engineering and other fields. The effect of the project: 1, the intensity is big, the creep is small, adapts to each kind of environmental soil, can satisfy the high grade highway in the high retaining wall.

- Q: Are geogrids resistant to temperature variations?

- Yes, geogrids are generally resistant to temperature variations. They are designed to withstand a wide range of temperatures, from extreme cold to intense heat, without significant degradation or loss of performance. This makes them suitable for various applications in different climate conditions.

- Q: How do geogrids enhance the performance of geocell confinement systems?

- Geogrids enhance the performance of geocell confinement systems by providing additional reinforcement and stability. They are integrated within the geocell walls, creating a stronger structure that can withstand higher loads and pressures. Geogrids also distribute the applied forces more evenly, preventing localized stress concentrations and reducing the risk of deformation or failure. Ultimately, the use of geogrids improves the overall performance and longevity of geocell confinement systems.

- Q: Where are the bi - directional bi directional 40kN geogrid, geogrid price, geo material suppliers

- Polyester geogrid mining geotechnical geogrid tensile plastic geogrid coal mine geogrid one-way plastic geogrid steel plastic geogrid warp knitted fiberglass geogrid

- Q: Glass steel grille is how to produce

- Production process of FRP grid:Preparation of mold - Preparation of mixed resin - glass fiber yarn - (or at the same time) pouring resin and exhaust bubble - mold heating, product curing - mold - finishing - Inspection packaging.

- Q: Can geogrids be used in reinforcement of underground storage tanks?

- Yes, geogrids can be used in the reinforcement of underground storage tanks. Geogrids provide additional stability and strength to the tank's structure, preventing soil and groundwater pressures from causing deformation or collapse. By reinforcing the surrounding soil, geogrids ensure the tank's integrity and longevity.

- Q: What is the market price of the geotechnical grid in 2017?

- (1) the first accurate release of subgrade slope line, in order to ensure the roadbed width of each side of the widened 0.5m, soil drying good leveling by 25T after vibroll pressure two times, then 50T shock pressure of four times, how much is the uneven supply market price? Datong geogrid. Datong geogrid products? Datong geogrid supply market price is how much? Datong geogrid. Datong geogrid products? Datong geogrid supply market price is how much? Datong geogrid. Datong geogrid products? Datong local earthwork grid with artificial coordination. (2) 0.3m thick medium (coarse) sand, artificial with mechanical leveling, 25T vibratory roller static pressure two times. (3) geogrid, geogrid laying bottom surface should be smooth, dense, should generally be tiled, straight, no overlap, no curl, kink, two pieces of geogrid adjacent to lap 0.2m, and along the horizontal Subgrade of geogrid overlap every 1 meters with 8 wire were interspersed in the grid connection, and laying on every 1.5-2m U nail is fixed on the ground.

Send your message to us

Vegetated Geogrids - Bitumen Coated Fiberglass Geogrid with High Tensile Strength

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords