Used Scaffolding Boards For Sale Formwork Steel Scaffolding Pipe Weights High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Used Scaffolding Boards For Sale Formwork Steel Scaffolding Pipe Weights High Quality

Column Formwork Outrigger For Scaffolding With New Design

Plastic Formwork Concrete Formwork Circular Column Used Scaffolding Props New Design

Developing with new technology materials, steel formworks is no longer a must in construction concrete process. More and more buildings are established with plastic formworks. And workers love this new formworks much more.

The advantages of plastic formworks:

1.First of all--light

Yes it is the first advantage of plastic formwork. It wins the great praise of both contractors and workers.

The biggest panel is 120×1500px,weights 10.5kg only. It can be lift and set up by one person easily, which means there is no need for cranes on site.Saves a lot of cost and time.

2.Easy set up

Different size of panels can firmly locked by simply turn the special handles to 90 degree. The Panels has rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

3.Modularity

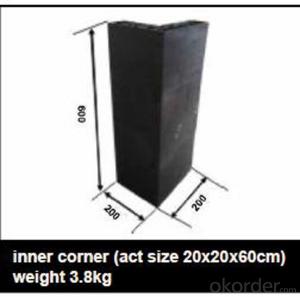

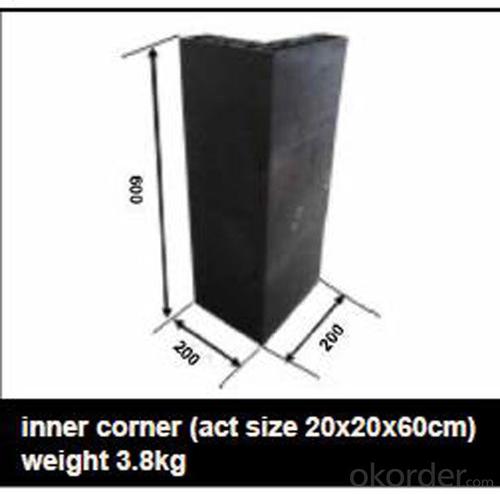

Modular formworks composed by different size of panels..

4.Strength

The handles are made by high strength Nilon, each panel locked by at least 4 handles, which makes the whole system strong enough to pour 1000px walls.

5.Environment friendly

The system needs no cut and nail due to the variety size. Also it needs nearly no wood. The material can be recycled after broken, so it will not pollute the environment.

6.Consequent

Concrete does not stick to plastic formwork, thus the panels need no oil before using, and can be cleaned simply by water. The surface of the wall which build by modular formwork is smooth and without rework.

Used Scaffolding Boards For Sale Formwork Steel Scaffolding Pipe Weights High Quality

Used Scaffolding Boards For Sale Formwork Steel Scaffolding Pipe Weights High Quality

Used Scaffolding Boards For Sale Formwork Steel Scaffolding Pipe Weights High Quality

Advantage

* Good loading capacity

* Easy to assemble and dismantle

* Stable and durable thanks to its structual design & automatic welding quality

* Customized solution helps you work safe, save cost and convenient

* Excellent quality for formwork & scaffolding with wide choices

Packing

in bulk or in bundle, or as requested

Shipping

15-20 Days.

Normally small orders, it needs just 15-20 business days to the port. For goods with stock, it would be even shoter.

Used Scaffolding Boards For Sale Formwork Steel Scaffolding Pipe Weights High Quality

Other scaffolding & formwork products:

(1) Scaffolding System:

Including Ringlock Scaffolding System and accessories; Cuplock Scaffolding System and accessories; Kwikstage Scaffolding System and accessories; Haki Scaffolding System and accessories;

(2) Scaffolding Frame & Accessories:

Including Walk Through Frame Scaffolding; Ladder Frame Scaffolding; Accessories; we also can make scaffolding according to your samples or drawings.

(3) Scaffolding Couplers/Clamps:

We can produce all kinds of forged and pressed couplers, including British type couplers, American type couplers, German type couplers, Italian type couplers ,fence couplers, BRC coplers and so on. We also can produce according to your drawings or samples.

FAQ Used Scaffolding Boards For Sale Formwork Steel Scaffolding Pipe Weights High Quality

Why Us?

We are one of the Top 500 in the world, largest construction materials supplier in China. Also we are a state-owned company and respond to every customer with large and also small orders.

We own professional manufacturers with powerful producing capacity.

Extensive and comprehensive quality control system

Excellent products with competitive prices.

Efficient services in pre and after sale.

Full energy with affluent experience team.

- Q: Does steel frame formwork require any specific surface preparation?

- Specific surface preparation is necessary for steel frame formwork before it is utilized. The steel frame's surface must undergo cleaning to eliminate dirt, rust, or any other impurities. To accomplish this, a wire brush or abrasive substance can be employed to eliminate loose or peeling paint, rust, or debris. Once the cleaning is completed, a primer or anti-corrosion coating should be applied to safeguard the steel against additional rust formation. This will guarantee that the steel frame formwork remains in optimal condition and offers a robust and steady structure for pouring concrete.

- Q: What are the different types of joints used in steel frame formwork?

- The different types of joints used in steel frame formwork include butt joints, lap joints, tongue and groove joints, and corner joints.

- Q: What are the cost implications of using steel frame formwork?

- The cost implications of using steel frame formwork can vary depending on several factors. Steel frame formwork is generally more expensive upfront compared to traditional timber formwork. However, it offers several advantages such as durability, reusability, and faster construction speed, which can offset the initial higher cost. Additionally, steel formwork requires less maintenance and has a longer lifespan, reducing overall costs in the long run. It also provides better structural integrity and accuracy, resulting in potential savings in material and labor costs. Ultimately, the cost implications of using steel frame formwork should be evaluated based on the specific project requirements, timeline, and budget.

- Q: How does steel frame formwork help in ensuring accurate alignment of concrete elements?

- Steel frame formwork is a construction technique that utilizes steel frames to create molds or formwork for pouring and shaping concrete elements such as walls, columns, and slabs. This method offers several advantages, one of which is its ability to ensure accurate alignment of these concrete elements. Firstly, steel frame formwork provides a strong and rigid structure that helps maintain the desired shape and dimensions of the concrete element during the pouring and curing process. The steel frames are precisely manufactured to meet the required specifications, ensuring that the formwork remains stable and does not deform or shift during the concrete placement. Furthermore, steel frame formwork allows for adjustable and precise alignment of the formwork components. The frames can be easily adjusted and aligned using various techniques such as leveling devices and adjustable clamps. This ensures that the formwork is perfectly aligned both horizontally and vertically, resulting in accurate and consistent concrete elements. In addition, the use of steel frame formwork enables the construction team to easily monitor and control the alignment of the concrete elements. The steel frames provide clear reference points and allow for accurate measurements and adjustments. This level of control helps to prevent any deviations or misalignments, ensuring that the concrete elements are built according to the required design and specifications. Moreover, steel frame formwork allows for efficient and precise installation of reinforcement bars within the formwork. The frames provide clear access and space for placing and securing the reinforcement bars accurately, ensuring that they are properly aligned within the concrete element. This reinforcement alignment is crucial for the structural integrity and strength of the concrete element. Overall, steel frame formwork plays a crucial role in ensuring accurate alignment of concrete elements. Through its strong and rigid structure, adjustable alignment capabilities, and precise installation of reinforcement, it provides the necessary support and control to achieve accurate and consistent concrete elements, resulting in a high-quality construction outcome.

- Q: How does steel frame formwork handle the placement of electrical and plumbing systems within the concrete structure?

- Steel frame formwork is a versatile and efficient method of constructing concrete structures, including the placement of electrical and plumbing systems. This formwork system allows for easy integration of these systems within the concrete structure. One of the main advantages of steel frame formwork is its flexibility. The formwork can be easily modified and adjusted to accommodate the placement of electrical and plumbing systems. The steel frames can be cut, drilled, and welded to create openings and channels for the installation of electrical conduits and plumbing pipes. Moreover, steel frame formwork provides a strong and stable structure for these systems. The steel frames provide robust support for the weight of the concrete and the additional load of electrical and plumbing systems. This ensures that the systems are securely embedded within the concrete structure without compromising its integrity. In addition, the steel frames can be pre-fabricated off-site, allowing for precise planning and coordination of the electrical and plumbing layouts. This reduces the on-site construction time and minimizes any potential disruption to the installation of these systems. Furthermore, steel frame formwork can accommodate various sizes and configurations of electrical and plumbing systems. The formwork can be customized to suit the specific requirements of the project, whether it involves small-scale residential buildings or large-scale commercial structures. This adaptability ensures that the electrical and plumbing systems can be seamlessly integrated into the concrete structure without any constraints. Overall, steel frame formwork provides a reliable and efficient solution for handling the placement of electrical and plumbing systems within the concrete structure. Its flexibility, strength, and adaptability make it an ideal choice for construction projects that require the seamless integration of these systems.

- Q: What are the different finishes available for steel frame formwork panels?

- There are several different finishes available for steel frame formwork panels, depending on the specific requirements of the construction project. Some of the most common finishes include: 1. Smooth Finish: This is the most basic finish option, where the steel frame formwork panels are left with a smooth surface. This finish is suitable for projects where a smooth concrete surface is desired. 2. Textured Finish: In some cases, a textured finish is preferred to provide better adhesion between the concrete and the formwork. This can be achieved by adding a texture to the surface of the steel frame formwork panels. 3. Powder Coating: Powder coating is a popular finish option for steel frame formwork panels. It involves the application of a dry powder to the surface, which is then heated to form a durable and protective coating. Powder coating can provide a smooth, even finish and can also offer enhanced corrosion resistance. 4. Galvanizing: Galvanizing is a process where a protective layer of zinc is applied to the surface of the steel frame formwork panels. This coating not only provides corrosion resistance but also improves the overall durability of the panels. 5. Paint Coating: Paint coating is another option for finishing steel frame formwork panels. It involves the application of a liquid paint to the surface, which provides both aesthetic appeal and protection against corrosion. It is important to consider factors such as durability, corrosion resistance, and aesthetic requirements when choosing the appropriate finish for steel frame formwork panels. Consulting with a construction professional or engineer can help determine the best finish option for a specific project.

- Q: Can steel frame formwork be used for both low-rise and high-rise buildings?

- Steel frame formwork is suitable for both low-rise and high-rise buildings. This versatile and durable system can withstand the weight and pressure of concrete during construction. It is easy to assemble and disassemble, making it adaptable to different building heights. Furthermore, the steel frame formwork can be customized to meet various floor layouts and structural needs. Its strength and stability make it an excellent option for both low-rise and high-rise construction projects.

- Q: How does steel frame formwork contribute to the overall constructability of a concrete structure?

- Steel frame formwork plays a crucial role in enhancing the overall constructability of a concrete structure. Its contribution can be observed in several key areas. Firstly, steel frame formwork provides a sturdy and durable framework for pouring and shaping the concrete. The steel frames are designed to withstand the pressure exerted by the liquid concrete, ensuring that it maintains its shape and integrity during the pouring process. This stability is essential for achieving precise and accurate dimensions in the final structure. Additionally, steel frame formwork allows for efficient and speedy construction. Its modular design enables easy assembly and disassembly, reducing the time required for formwork installation and removal. This time-saving aspect is especially beneficial in large-scale construction projects, where the ability to quickly move formwork from one area to another can significantly expedite the overall construction timeline. Moreover, steel frame formwork facilitates flexibility and adaptability during the construction process. The modular components can be adjusted and reconfigured to accommodate various architectural and design requirements. This versatility allows for the creation of complex structures with unique shapes and dimensions. Furthermore, steel frame formwork contributes to the overall safety of the construction site. The robustness of the steel frames ensures that the formwork can withstand external forces such as wind or vibrations, reducing the risk of accidents or collapse. Additionally, the use of steel formwork eliminates the need for excessive propping, further enhancing the safety of the construction site. In conclusion, steel frame formwork greatly enhances the constructability of a concrete structure by providing stability, efficiency, flexibility, and safety. Its durable framework, modular design, and adaptability contribute to the accurate and timely construction of high-quality concrete structures.

- Q: What are the common applications of steel frame formwork?

- Steel frame formwork is a versatile construction technology that is widely used in various applications. Some of the common applications of steel frame formwork include: 1. High-rise buildings: Steel frame formwork is commonly used in the construction of high-rise buildings due to its strength and durability. It provides a stable and rigid structure for concrete casting, allowing for efficient construction of tall structures. 2. Bridges and tunnels: Steel frame formwork is also frequently used in the construction of bridges and tunnels. Its robustness and ability to withstand heavy loads make it ideal for these types of infrastructure projects. 3. Industrial structures: Steel frame formwork is widely used in the construction of industrial structures such as factories, warehouses, and power plants. Its ability to handle large volumes of concrete and provide a sturdy framework makes it suitable for these applications. 4. Residential buildings: Steel frame formwork is commonly employed in the construction of residential buildings, including apartments, condominiums, and housing complexes. Its versatility allows for the creation of various shapes and sizes, accommodating different architectural designs. 5. Infrastructure projects: Steel frame formwork is crucial in infrastructure projects such as dams, canals, and water treatment plants. These projects often require large-scale concrete casting, and the strength of steel formwork ensures the integrity and stability of the structures. 6. Commercial and institutional buildings: Steel frame formwork finds extensive use in the construction of commercial and institutional buildings, including offices, schools, hospitals, and shopping malls. Its efficiency and cost-effectiveness contribute to faster construction timelines and reduced project costs. Overall, steel frame formwork is widely utilized in various construction applications due to its strength, durability, and versatility. Its ability to provide a stable framework for concrete casting makes it an essential technology in the construction industry.

- Q: Frame structure calculation of the material, the template area, and how to calculate the amount of wood, steel, fasteners, there is no common factor ratio? The column spacing of 6000

- (two) the construction of the deployment of 1 construction organization, according to the characteristics of this project, the company decided to set up a clever and capable project manager, construction team during the fight in the diversion project construction, and key projects included in the company's 2003 annual, as the focus to ensure in human, financial and material. The tree image, a brand, and always will be the quality, schedule, safety thread throughout the construction process, to ensure the realization of the goal. (1) the project decision-making level, composed of the project manager, deputy manager, technical director of the project exercise, organization, coordination, control, supervision and command functions. The project manager shall be entrusted by the legal representative, and shall be responsible for the execution and completion of the contents of the contract agreement signed by the company and the owner, in charge of the financial and personnel arrangements

Send your message to us

Used Scaffolding Boards For Sale Formwork Steel Scaffolding Pipe Weights High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords