Unilateral Formwork Support System

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

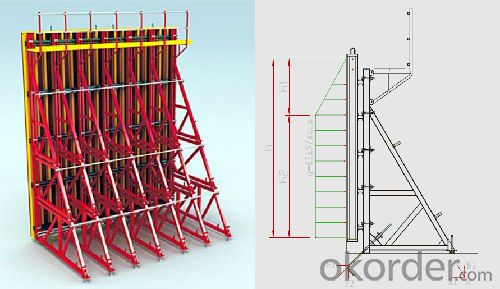

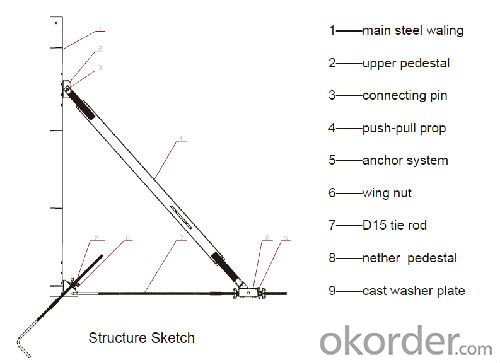

1. Structure of Unilateral Formwork

Unilateral bracket is composed of embedded parts system part and the frame body is composed of two parts, including:The system includes embedded parts: anchor bolt, nut, connecting the outer-link, the outer nut and beams.

According to your requirements of the project selection frame height has the following two kinds of specifications: H=3600 standard section, section H=3200 height.

2. Main Features of Unilateral Formwork

◆ For concrete heights up to 8.0m and a fresh concrete pressure up to a maximum of 60KN/m2.

◆ Good standard performance and versatility.

◆ Fast element coupling, all units can be quickly connected.

◆ The finished wall is excellent and absolutely waterproof.

◆ Optimized sizes for transportation.

3. Unilateral Formwork Images

4. Unilateral Formwork Specification

5. FAQ of Unilateral Formwork

1) What can we do for you?

We can ensure the quality of the Unilateral Formwork and avoid extra expenses for customers.

We can provide you the professional design team.

We can provide fashionable and newest styles for you.

We can design the artwork for you.

Please feel free to customize.

2) What promises can be done by us?

If interested in Unilateral Formwork, please feel free to write us for any QUOTE.

If printing required, please advise asap because the whole set need much more time to complete.

Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

Response will be carried out in 24hours after receiving any complain or request.

If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

Packing: As Customer's Requirements

Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

Shipping time:Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days. Other mass qty of Unilateral Formwork, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: Scaffolding structure template support frame type

- Fastener, bowl button and door steel scaffold material can be used to construct the template support frame, and have their own characteristics. According to their structure can be classified as follows: (1) by type of structure 1) pillar support frame (pillar bearing structure);

- Q: Roof plate support combination structure

- Xingmin Weiye roof plate template support structure is one of my company's patented product, the roof template support combination structure by the main keel, vice keel, supporting the top of the bar, the tie rod together, the four together form a roof template support system.

- Q: More than a certain size of the larger risk of the template works and support system which include

- Always looking at someone else to go to bargain-hunting that is difficult, others are very HIGH when you do not HIGH, the results of the market start, you unconsciously. Baidu search

- Q: Bridge template support bowl button steel pipe scaffolding, need to set sweeping pole?

- Scaffolding must be set to vertical and horizontal sweepers. Longitudinal sweeping pole should be fixed at right angles to the base of the epithelium is not greater than 200mm on the pole, the horizontal sweep pole should also be used at right angle fasteners fixed in the vertical under the pole on the pole. When the base of the pole is not at the same height, the height of the longitudinal sweeping pole must be extended to the lower span of the two spans and the pole fixed, the height difference should not be greater than 1M. The distance from the pole shaft above the slope to the slope should not be less than 500mm.

- Q: How to use template support?

- According to your picture, you can determine this is the cast-in-place concrete board full of support. Generally set full support, the distance between the support in general according to the vertical and horizontal 600mm spacing to consider, the lower part of the distance from the standing surface of 200mm set sweep, the middle set a horizontal bar, the upper part of the beam at the end of the set of cross bar, mainly play a role in supporting the beam plate.

- Q: Building template support structure has been widely used

- In the current housing construction are required to achieve a certain level of engage in shock, so the general buildings are cast-in-place floor and shear wall structure, so the construction template support structure has been widely used, the national timber increasingly depleted, the domestic north and south are limited Deforestation, steel shear wall template support will become a trend in the future cast-in-place concrete support frame.

- Q: Unilateral support basement wall waterproof protective layer do not do it? Will there be a broken ring on the waterproofing membrane? Is it possible to destroy the process?

- Exterior wall waterproofing is a branch waterproofing project that ensures that the structure of a building (structure) is not affected by water and that the internal space is not covered by water. Exterior wall waterproofing works in the entire construction project occupies an important position. Exterior wall waterproofing works related to the building (structure) of the basement walls, housing facades and many other external wall structure, its function is to make the building or structure in the design of durable years, to prevent rain, water leakage and groundwater Of the erosion, to ensure that the building structure, the internal space is not subject to defacement, to provide people with a comfortable and safe living environment.

- Q: Template Support System Safety Control

- When the template is removed, the strength of the concrete must meet the requirements of the Code for Construction and Acceptance of Concrete Structures. Load-bearing template, beam and other cast-in-place structure when the demolition of concrete required to achieve the required strength when the demolition mode. In the demolition process, if found that the actual structure of concrete strength does not meet the requirements, should be suspended mold, the proper treatment, the actual strength to meet the requirements before they can continue to remove.

- Q: In addition, for example, in the 30-meter-high pier body pouring continuous beam 0 # block, beam 0 # block can be used to support the bracket (usually block 0 block will be surrounded by the entire pier), but 30 meters high Of the scaffolding if not connected with the bracket, then what is the way to make the stability of scaffolding requirements? Is it only anchoring? Please master answer.

- The use of pier body construction rod hole, so that scaffolding and pier body consolidation, improve stability

- Q: There are experts to demonstrate the high-support model, the template support frame erected there is no requirement must be held by the shelves of special operations card can be erected carpenters can not erect a search

- Must be held by the shelves of special operations card can be erected

Send your message to us

Unilateral Formwork Support System

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords