Uni-directional Plastic Geogrid Slope Erosion Geocells

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item:PP Uniaxal geogird

1.Material:PP

2.Tensiel strength:30KN/M

3.Size:2.5m*50M

4. Elongation:10%

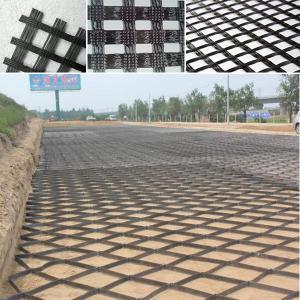

Uniaxial geogrid ,made of high molecular polymer ,is extruded into sheet and then punched into regular mesh patten,and finally stretched in the longitudinal direction.

Feature:

With high tensile strength and tensile modulus

Function:

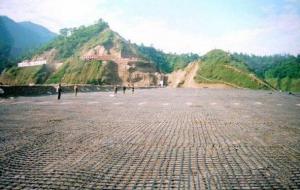

Uniaxial goegrid is mainly applied in highway,railway,slope protecting projects,retaining wall,dam to strengthen land loading capacity and extend its service life.Features in reducing area,project cost and matentainence cost,convenient to construct.

- Q: Are geogrids suitable for reinforcing embankments?

- Yes, geogrids are suitable for reinforcing embankments. Geogrids are made of strong materials such as polyester or polypropylene and are designed to provide stability and strength to soil structures. They can be used to reinforce embankments by distributing load more evenly, reducing soil movement, and improving overall stability. Geogrids also help prevent erosion and increase the overall lifespan of embankments.

- Q: Geogrid tgsg45-45 what does it mean

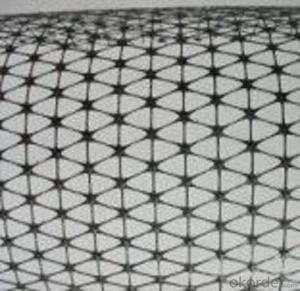

- Geogrid TGSG45-45, two-way plastic geogrid 45KN, I hope to help you.

- Q: What are the different materials used to manufacture geogrids?

- Geogrids are commonly manufactured using materials such as polyester, polypropylene, fiberglass, and steel.

- Q: How do geogrids improve soil confinement?

- Geogrids improve soil confinement by providing a strong and stable reinforcement that helps to distribute the load more evenly across the soil. This prevents soil movement and slippage, enhancing the overall stability and strength of the soil.

- Q: How to effectively control the quality of Geogrid in the process of construction

- 2 the surface of the bearing surface of the geosynthetics shall be leveled and compacted, and the hard and protruding surface shall be removed.

- Q: Are geogrids suitable for use in reinforced steep slopes?

- Yes, geogrids are suitable for use in reinforced steep slopes. Geogrids provide additional strength and stability to the soil, preventing erosion and maintaining the integrity of the slope. They are designed to withstand high tensile forces, making them ideal for reinforcing steep slopes and preventing soil movement.

- Q: I asked what the raw materials needed for the production were, for example, what the green mesh was made of

- Building safety net, also can be called the steel plastic geogrid. Steel grating and construction safety net (protective net) welded together

- Q: Can geogrids be used in retaining walls for highway projects?

- Yes, geogrids can be used in retaining walls for highway projects. Geogrids are commonly used in such projects to reinforce soil and provide stability to the retaining walls. They enhance the overall strength and durability of the walls, making them a reliable choice for highway construction.

- Q: What is the meaning of 400g geotextiles /100g woven fabric

- Should be a layer of woven cloth PE film and a layer of geotextile. PE membrane and geotextile 400g

- Q: Can geogrids be used in temporary slope stabilization applications?

- Yes, geogrids can be used in temporary slope stabilization applications. Geogrids are commonly used in various soil reinforcement projects, including slope stabilization. They provide strength and stability to the soil, preventing erosion and potential slope failures. However, it is important to note that the selection and design of geogrids for temporary slope stabilization should be done based on the specific project requirements and site conditions.

Send your message to us

Uni-directional Plastic Geogrid Slope Erosion Geocells

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords