High Tensile Geogrid Plastic Geogrid Embedment Length of Geogrids MSE Walls Factory Supply

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Geogrid:

1. Prevent road collapse and crack

2. Prevent soil and water loss in slope

Applications of Geogrid:

Make reinforce treatment for various kinds of soft soil foundation to evenly distribute load stress and reduce uneven settlement, not easy to generate static electricity, and flammability property good in the coal mine. It is easy to wash coal.

Used in highway, railway, port, airport and municipal project. Support in the recovery working face of coal mine and roadway in the coal mine.

Index Properties | Test Method | Unit | GG1515 | GG2020 | GG3030 | GG4040 |

MD TD | MD TD | MD TD | MD TD | |||

Polymer | -- | -- | PP | PP | PP | PP |

Minimum Carbon Black | ASTM D 4218 | % | 2 | 2 | 2 | 2 |

Tensile Strength@ 2% Strain | ASTM D 6637 | Kn/m | 5 5 | 7 7 | 10.5 10.5 | 14 14 |

Tensile Strength@ 5% Strain | ASTM D 6637 | Kn/m | 7 7 | 14 14 | 21 21 | 28 28 |

Ultimate Tensile Strength | ASTM D 6637 | Kn/m | 15 15 | 20 20 | 30 30 | 40 40 |

Strain @ Ultimate Strength | ASTM D 6637 | % | 13 10 | 13 10 | 13 10 | 13 10 |

Structural Integrity | ||||||

Junction Efficiency | GRI GG2 | % | 93 | 93 | 93 | 93 |

Flexural Rigidity | ASTM D 1388 | Mg-cm | 700000 | 1000000 | 3500000 | 10000000 |

Aperture Stability | COE Method | mm-N/deg | 646 | 707 | 1432 | 2104 |

Dimensions | ||||||

Roll Width | -- | M | 3.95 | 3.95 | 3.95 | 3.95 |

Roll Length | -- | M | 50 | 50 | 50 | 50 |

Roll Weight | -- | Kg | 39 | 50 | 72 | 105 |

MD denotes Machine direction. TD denotes transverse direction. | ||||||

Property of Geogrid:

1.) Improve roadbed bearing capacity,enlarge road lifetime.

2.) Prevent road collapse and crack

3.) Prevent soil and water loss in slope

4.) Could replace steel-plastic geogrid in coal mine.

FAQ:

1. How to order your geogrid ?

a). Tensile strength in warp & weft direction

b). Grid size

c). Width and length

d). Quantity

2. Payment term .

a) TT

b) LC AT SIGHT

c) cash

d) 30% contact value as deposit ,the blance 70% be paid after received the copy of bl .

3. Delivery time

a) 19-25 days after received your depsit .

4. What is MQQ ?

a) 2500 m2 as MQQ , we can also produce sample for you .

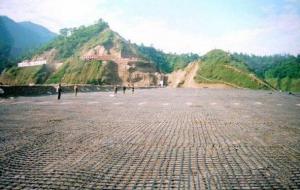

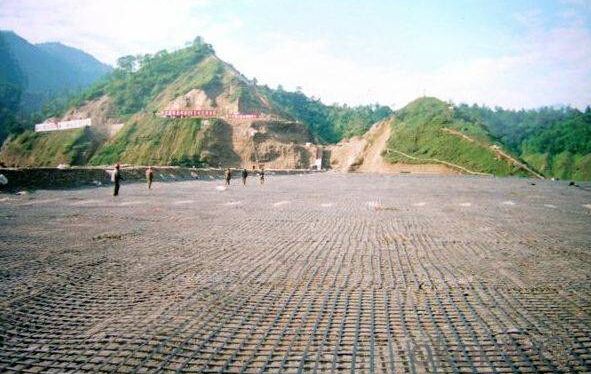

Geogrid Show:

- Q: What are the countries of China's anti dumping

- 1) flat field: laying 50cm thick sandstone gravel or sand and gravel cushion compaction (egg) is conducive to increase frictional resistance between soil and geogrid to base consolidation 2) should pay attention to the connection between laying grille grille and vertical grille grille straight smooth laying according to the design position along the road to base

- Q: Are geogrids suitable for reinforcing bridge abutment backfills?

- Yes, geogrids are suitable for reinforcing bridge abutment backfills. Geogrids provide increased stability and load-bearing capacity to the soil, preventing erosion and settlement. They distribute the load evenly, reducing the risk of structural damage to the bridge abutment. Additionally, geogrids improve the long-term performance and durability of the backfill materials.

- Q: Can geogrids be used in underwater applications?

- Yes, geogrids can be used in underwater applications. They are often used to stabilize soil and prevent erosion in underwater environments such as riverbanks, shorelines, and underwater slopes. Geogrids are designed to withstand the hydraulic forces of water and provide long-term stability in these challenging conditions.

- Q: What are the benefits of using geogrids in retaining walls?

- The benefits of using geogrids in retaining walls include increased stability, improved load-bearing capacity, reduced soil erosion, and longevity of the structure. Geogrids reinforce the soil, preventing it from sliding or collapsing under pressure, making the retaining wall more durable and resilient. Additionally, geogrids distribute the loads evenly, reducing the risk of settlement and enhancing the overall performance of the wall. They also enhance drainage and filtration, minimizing water buildup behind the wall and preventing soil erosion. Overall, geogrids help to ensure the longevity and effectiveness of retaining walls.

- Q: How do geogrids help in reducing soil settlement?

- Geogrids help in reducing soil settlement by providing reinforcement and stability to the soil structure. They restrain the lateral movement and spread the load more evenly, preventing excessive settlement.

- Q: How do geogrids improve the performance of flexible retaining walls?

- Geogrids improve the performance of flexible retaining walls by providing reinforcement and stability to the soil behind the wall. They help distribute the lateral pressure from the retained soil, reducing the risk of wall failure. Additionally, geogrids increase the overall strength of the wall, allowing it to withstand greater loads and forces.

- Q: Geogrid is mainly used for what?

- Bi directional plastic geogrid is suitable for various highway and railway subgrade reinforcement. Increase the bearing capacity of the roadbed, prolong the service life of the roadbed; prevent the cracks on the road surface, reduce the maintenance cost and shorten the construction period.Bi directional geogrid is suitable for large parking lot and wharf freight yard, etc.. The bearing capacity of the foundation is increased and the ground is prevented from collapsing. The utility model has the advantages of beautiful and neat appearance, convenient construction, time saving and labor saving.Bidirectional geogrid is applied to the two reinforcement of the soil slope reinforced by unidirectional plastic geogrid.1, to further enhance the slope, to prevent soil erosion, convenient transportation;2, the use of vegetation growth, beautify the environment, reduce pollution.Bidirectional geogrid is suitable for railway and highway slope protection.1, to prevent rock slides, causing harm to people or vehicles;2, to maintain the railway, highway unblocked.Bidirectional geogrid is suitable for highway, railway and culvert.1, to prevent cracks in culvert, reduce maintenance costs;2, reduce the thickness of the surface, save costs; played a filter - protection.

- Q: Can geogrids be used in floating parking lot construction?

- Yes, geogrids can be used in floating parking lot construction. Geogrids are commonly used in various civil engineering applications, including building parking lots. They help reinforce the ground and distribute loads, making them ideal for stabilizing the soil beneath floating parking lots.

- Q: Why steel plastic geogrid in the test, will choose to peel out a single wire test? What are the causes and sources of this method

- Personal feeling can not do, at present, did not find the corresponding three to the geogrid test specification, how to determine the direction of the three cells, how to load are not standardized

- Q: Can geogrids be used in erosion control applications on steep slopes?

- Yes, geogrids can be used in erosion control applications on steep slopes. Geogrids are often employed in such situations to stabilize the soil and prevent erosion by providing reinforcement and increasing the overall strength of the slope.

Send your message to us

High Tensile Geogrid Plastic Geogrid Embedment Length of Geogrids MSE Walls Factory Supply

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords