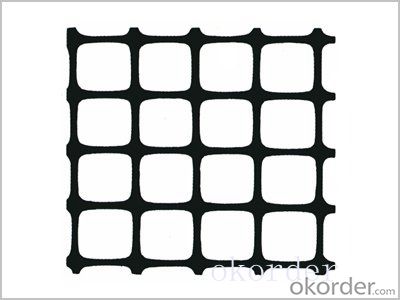

High Tensile Strength Steel Plastic Geogrids for Slope Erosion Geocells Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

Type:

Geogrids

Place of Origin:

Anhui, China (Mainland)

Brand Name:

CMAX

Model Number:

Biaxial

Product Introduction

The Steel plastic composite geogrid is by the high tensile steel wire, after the special handing, with the polyethylene(P. E), and increase other assistants, though squeezes out causes it excel to become the mult-skill anti-to pull the banding, and the surface has the rough embossing, for excel in reinforcement earthwork belt. From this as soon as the single belt, after vertical, according to decides the spacing knitting horizontally or clamps gathers the arrangement, uses the ultrasonic welding to molding.

The Steel plastic composite geogrid is by the high tensile steel wire, after the special handing, with the polyethylene(P. E), and increase other assistants, though squeezes out causes it excel to become the mult-skill anti-to pull the banding, and the surface has the rough embossing, for excel in reinforcement earthwork belt. From this as soon as the single belt, after vertical, according to decides the spacing knitting horizontally or clamps gathers the arrangement, uses the ultrasonic welding to molding.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: PVC HF what is the material PVCHF bidirectional geogrid is like?

- Polyvinylchloride, PVC: polymer with random configuration of repeating units

- Q: What is the effect of installation damage on geogrid performance in long-term applications?

- Installation damage can have a significant impact on the performance of geogrids in long-term applications. Damage during installation, such as improper handling, stretching, or tearing, can reduce the structural integrity of the geogrid. This can result in decreased load-bearing capacity, reduced soil confinement, and potential failure of the geogrid system over time. It is crucial to ensure proper installation techniques and quality control measures to minimize installation damage and maintain optimal geogrid performance in long-term applications.

- Q: Can geogrids be used in slope stabilization for railway embankments with high water table conditions?

- Yes, geogrids can be used in slope stabilization for railway embankments with high water table conditions. Geogrids are commonly used in such situations to reinforce and stabilize the soil, preventing erosion and maintaining the integrity of the slope. Their high tensile strength and ability to distribute loads make them suitable for railway embankments with high water table conditions.

- Q: What is a civil grille

- The civil grille is also called the geogrid, which is made of polypropylene, polyvinyl chloride and other high molecular polymer, which is made of thermoplastic or molded two dimensional grid or a three-dimensional grid screen with a certain height,

- Q: Definition of GeotextilesWhat are what material, what role

- The nonwoven geotextile is composed of at least two sets of parallel yarns (or flat), along with a group of loom (fabric longitudinal direction) called warp, another group called weft. Lateral arrangement with different preparation of weaving equipment and process of warp and weft interwoven with woven cloth like. According to the different scope woven into different thickness and density, generally the nonwoven geotextile thin longitudinal tensile strength is very strong (latitude, longitude is greater than) has good stability properties. The nonwoven geotextile according to the knitting technology and use the latitude is divided into different geosynthetic cloth and reinforced geotextile two categories, reinforced geotextile warp tensile strength is far greater than the ordinary geotextile. The nonwoven geotextile general application and geotechnical engineering project reinforcement, the main function is reinforced, with planar isolation and protection function, not out The plane drainage function can be selected according to the specific purpose

- Q: How do geogrids improve pavement performance?

- Geogrids improve pavement performance by reinforcing the asphalt or concrete layers, increasing their strength and preventing cracks and deformations. They distribute the load more evenly, reduce fatigue and rutting, and enhance the overall durability and lifespan of the pavement.

- Q: Can geogrids be used in reinforcement of underground utility corridors?

- Yes, geogrids can be used in the reinforcement of underground utility corridors. Geogrids are commonly used in civil engineering applications to provide strength and stability to soil, including underground structures such as utility corridors. They are effective in distributing load and preventing soil movement, enhancing the overall performance and durability of the underground utility corridors.

- Q: Can geogrids be used in bridge abutment construction?

- Yes, geogrids can be used in bridge abutment construction. Geogrids are often used as reinforcement materials in soil structures, including bridge abutments, to improve the stability and strength of the soil. They can help distribute loads and reduce settlement, making them a valuable addition to bridge abutment construction projects.

- Q: What is the difference between nonwoven geotextiles and geotextile? What is their role?

- Nonwoven geotextile filter is a kind of nonwoven geotextile which can be used for water and water filtration.

- Q: What are the long-term effects of using geogrids?

- The long-term effects of using geogrids include improved soil stability and increased load-bearing capacity, leading to reduced soil erosion and enhanced durability of structures. Additionally, geogrids can contribute to long-lasting pavement performance, reduced maintenance costs, and extended lifespan of infrastructure projects.

Send your message to us

High Tensile Strength Steel Plastic Geogrids for Slope Erosion Geocells Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords