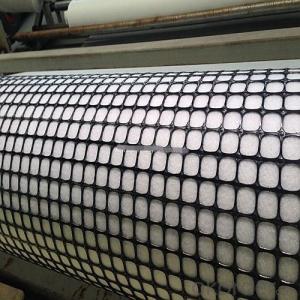

Uniaxial and Biaxial Geogrids Reinforced Composite Geotextile with Membrane and Nonwoven Geotextiles for Civil Engineering

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

composite geotextile with membrane,nonwoven Geotextiles In Civil Engineering

1) Weight:100gsm-1500gsm

2) width:Within 8m

3)le

composite geotextile with membrane,nonwoven Geotextiles In Civil Engineering

Product Description

Geotextiles also called geotextile fabrics, it’s permeable geosynthetics made of synthetic fibers through woven or needle punched.

Geotextiles including :needle punched nonwoven geotextile , filament woven geotextile , split yarm PP woven geotextile,composite geotextile + geomembrane,Geotextile Bags.

1) Staple fibers needle punched non woven geotextile

The geotextile is made of polypropylene staple fibers on cross-laying equipment and needle punched equipment.

It owns the advantages of acid and alkali resistance, erosion resistance, aging resistance, large strength, stable size, good filtrability etc.

2 ) Filament non woven geotextile

Filament geotextile has features as follows: High strength, good capacity of elongation and high biology tolerance, alkali tolerance, acidity tolerance, weather resistance good filtration and fine drainage capacity etc. Also it is of low cost, easy in construction and use effects.

3) Geotextile membrane:

1. One piece of geotextile and one piece of membrance :Wight:100~1000/m2 , Thickness : 0.1~1.5mm

2. Two piece of geotextile and one piece of membrance :Wight:80~600/m2 , Thickness : 0.2~1.5mm

3. One piece of geotextile and two piece of membrance : Wight:100~1000/m2 , Thickness : 0.1~0.8mm

4. multi-layers :Wight:100~1000/m2 , Thickness : 0.1~0.8mm

Flexibility is good,except of geotextile's isolation,drainage, reinforcement,protective functions,It is also impermeable.

Usage: Widely used in dam,traffic tunnel,road,airport,drainage,housing,environmental protection and other fields for waterproof protection,reinforcement etc.

- Q: What is the meaning of two-way 50kN geogrid

- The code is GSL, GSL50 represents the longitudinal and transverse tensile strength more than 50KN of plastic geogrids.

- Q: Definition of GeotextilesWhat are what material, what role

- Nonwoven geotextile:A non-woven cloth is made of filament or staple through the equipment and technology of different laying into the mesh, after acupuncture process for different fiber intertwined intertwined fixing fabric specification, make the fabric soft, plump, thick, stiff, to achieve different thickness to meet the use requirements, non-woven geotextile fabric has good clearance, good adhesion, because the soft fiber has certain anti tear ability and ability to adapt to the deformation of good, and has good drainage capacity of plane surface, soft multi gap has good friction coefficient can increase the soil particle etc. the ability of adhesion, can prevent fine particles by preventing particulate loss and eliminate excess water, soft surface protection ability is very good. In accordance with the length of wire is divided into non-woven geotextile filament or staple nonwoven geotextile. The utility model has the advantages of good filtration, isolation, reinforcement, protection, etc. the utility model is a wide application of geosynthetics, and the tensile strength of the filament is higher than that of the short filament, which can be selected according to the specific requirementsWoven geotextile (reinforced geotextile):

- Q: Can geogrids be used in retaining wall facing systems?

- Yes, geogrids can be used in retaining wall facing systems. Geogrids are commonly used as reinforcement elements in retaining walls to enhance their stability and strength. They are placed within the soil layers behind the facing system to increase the resistance against lateral forces, reducing the potential for wall failure. By providing additional support, geogrids help to distribute the loads evenly and improve the overall performance of the retaining wall facing system.

- Q: What are the advantages of using geogrids in ground improvement for settlement control?

- Geogrids offer several advantages in ground improvement for settlement control. Firstly, they provide increased soil stability by distributing loads more evenly, thereby reducing settlement and preventing soil erosion. Secondly, geogrids enhance soil reinforcement, increasing the bearing capacity of the ground and allowing for the construction of heavier structures. Additionally, these materials are easy to install and cost-effective, saving time and money during the ground improvement process. Overall, geogrids offer a reliable and efficient solution for settlement control and improved ground stability.

- Q: What is the single geogrid 60kN/m

- Unidirectional geogrid, the tensile strength is not less than 60 kn per meter

- Q: Can geogrids be used in temporary construction platforms?

- Yes, geogrids can be used in temporary construction platforms. Geogrids are commonly used in construction projects to reinforce soil and provide stability. They can be used as a cost-effective solution for temporary construction platforms by improving load-bearing capacity and preventing soil erosion.

- Q: What is the recommended geogrid connection method for specific applications?

- The recommended geogrid connection method for specific applications depends on factors such as the type of soil, slope angle, and expected load conditions. Some common geogrid connection methods include mechanical connectors, welded connections, and soil wrap-around techniques. It is important to consult with a geotechnical engineer or follow manufacturer's recommendations to determine the most suitable connection method for a specific application.

- Q: What are the different types of geogrids available?

- There are several different types of geogrids available, including uniaxial geogrids, biaxial geogrids, and triaxial geogrids. Uniaxial geogrids are designed to primarily provide tensile strength in one direction, while biaxial geogrids offer strength in both directions. Triaxial geogrids, on the other hand, provide strength in all three directions. Each type of geogrid is used for specific applications depending on the desired level of reinforcement required.

- Q: What is the typical geogrid roll weight for specific applications?

- The typical geogrid roll weight for specific applications can vary depending on the specific type and purpose of the geogrid. However, geogrid rolls commonly range in weight from 200 to 1,000 pounds, with some heavier-duty options weighing even more for specialized applications.

- Q: How do geogrids enhance the performance of geosynthetic clay liner capillary barriers?

- Geogrids enhance the performance of geosynthetic clay liner capillary barriers by providing additional reinforcement and stability to the liner. They prevent the clay liner from shifting or deforming under the load of the overlying soil or water, thus maintaining its integrity as a capillary barrier. Geogrids also improve the overall tensile strength and load-bearing capacity of the liner system, enhancing its ability to resist stress and prevent the migration of contaminants.

Send your message to us

Uniaxial and Biaxial Geogrids Reinforced Composite Geotextile with Membrane and Nonwoven Geotextiles for Civil Engineering

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords