Polymer Geogrids Reinforced Nonwoven Geotextiles in Civil Engineering Composite Geotextile with Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

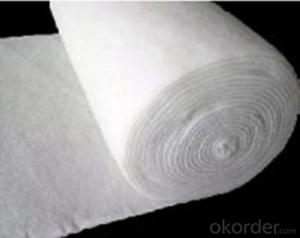

composite geotextile with membrane,nonwoven Geotextiles In Civil Engineering

1) Weight:100gsm-1500gsm

2) width:Within 8m

3)le

composite geotextile with membrane,nonwoven Geotextiles In Civil Engineering

Product Description

Geotextiles also called geotextile fabrics, it’s permeable geosynthetics made of synthetic fibers through woven or needle punched.

Geotextiles including :needle punched nonwoven geotextile , filament woven geotextile , split yarm PP woven geotextile,composite geotextile + geomembrane,Geotextile Bags.

1) Staple fibers needle punched non woven geotextile

The geotextile is made of polypropylene staple fibers on cross-laying equipment and needle punched equipment.

It owns the advantages of acid and alkali resistance, erosion resistance, aging resistance, large strength, stable size, good filtrability etc.

2 ) Filament non woven geotextile

Filament geotextile has features as follows: High strength, good capacity of elongation and high biology tolerance, alkali tolerance, acidity tolerance, weather resistance good filtration and fine drainage capacity etc. Also it is of low cost, easy in construction and use effects.

3) Geotextile membrane:

1. One piece of geotextile and one piece of membrance :Wight:100~1000/m2 , Thickness : 0.1~1.5mm

2. Two piece of geotextile and one piece of membrance :Wight:80~600/m2 , Thickness : 0.2~1.5mm

3. One piece of geotextile and two piece of membrance : Wight:100~1000/m2 , Thickness : 0.1~0.8mm

4. multi-layers :Wight:100~1000/m2 , Thickness : 0.1~0.8mm

Flexibility is good,except of geotextile's isolation,drainage, reinforcement,protective functions,It is also impermeable.

Usage: Widely used in dam,traffic tunnel,road,airport,drainage,housing,environmental protection and other fields for waterproof protection,reinforcement etc.

- Q: What is the meaning of two-way 50kN geogrid

- Ministry of industry standards

- Q: Can geogrids be used in slope stabilization?

- Yes, geogrids can be used in slope stabilization. Geogrids are commonly employed in slope stabilization projects to reinforce the soil and prevent erosion. They provide tensile strength and distribute the load, thereby improving the stability of the slope.

- Q: How do geogrids improve the performance of mechanically stabilized slopes in expansive soils?

- Geogrids improve the performance of mechanically stabilized slopes in expansive soils by providing reinforcement and stability to the soil mass. They prevent excessive movement and deformation of the soil, reducing the risk of slope failure and erosion. The geogrids distribute the load applied on the slope more evenly, enhancing its overall strength and preventing the development of cracks and settlements. Additionally, geogrids can control the lateral spreading of expansive soils, minimizing the potential for slope instability.

- Q: How are geogrids used in civil engineering?

- Geogrids are extensively used in civil engineering for reinforcing soil structures, such as retaining walls, slopes, and pavements. These geosynthetic materials provide increased stability and load-bearing capacity to the soil, preventing erosion and improving overall structural integrity. They are typically incorporated into the soil layers during construction, acting as a reinforcement to distribute the loads more effectively and reduce potential settlement or failure.

- Q: How much is a glass fiber mesh

- Alkali resistant glass fiber mesh cloth big price difference, and the alkali resistant glass fiber mesh quality, high tensile strength, elasticity, tensile strength and elongation between alkali resistant glass fiber mesh elastic limit, so the glass fiber mesh cloth price range is large, with "Jining wellav" WL-0812 series products the price, floating in the price range of $0.32--5

- Q: Are geogrids effective in reducing pavement rutting?

- Yes, geogrids are effective in reducing pavement rutting. Geogrids provide reinforcement to the pavement structure, distributing loads and reducing the stress on the pavement surface. This helps to prevent the formation and progression of rutting, resulting in improved pavement performance and longevity.

- Q: Can geogrids be used in reinforcement of mechanically stabilized earth bridge abutments on collapsible soils?

- Yes, geogrids can be effectively used in the reinforcement of mechanically stabilized earth (MSE) bridge abutments on collapsible soils. Geogrids are commonly used in MSE structures to provide additional strength and stability by improving soil retention and preventing lateral movement. In the case of collapsible soils, geogrids can help distribute the applied loads more evenly, reducing the risk of soil settlement and potential bridge abutment failure. Therefore, incorporating geogrids in the reinforcement of MSE bridge abutments on collapsible soils can be a reliable and efficient solution.

- Q: Can geogrids be used in ground stabilization for pipelines?

- Yes, geogrids can be used in ground stabilization for pipelines. Geogrids are commonly used in civil engineering applications to reinforce soil and provide stability to structures. In the case of pipelines, geogrids can be used to prevent soil erosion, improve load distribution, and increase the overall stability of the ground, thereby enhancing the long-term performance and safety of the pipeline.

- Q: Can geogrids be used in reinforcement of underground storage tanks?

- Yes, geogrids can be used in the reinforcement of underground storage tanks. Geogrids are commonly used in civil engineering applications to improve the stability and load-bearing capacity of soil structures. When used in the reinforcement of underground storage tanks, geogrids help distribute the load more evenly, reduce stress on the tank walls, and increase the overall strength and stability of the tank system.

- Q: What are the factors to consider in selecting a geogrid for a specific application?

- When selecting a geogrid for a specific application, several factors need to be considered. These factors include the required strength and durability of the geogrid, the type and condition of the soil being reinforced, the anticipated load or traffic on the geogrid, the climate and environmental conditions of the project site, and the cost-effectiveness of the geogrid. Additionally, factors such as installation requirements, compatibility with other materials, and the availability of the geogrid in the required dimensions and specifications should also be taken into account.

Send your message to us

Polymer Geogrids Reinforced Nonwoven Geotextiles in Civil Engineering Composite Geotextile with Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords