Hot Rolled Steel Equal Angle Bar Unqual Angle Bar Structure Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled Steel Equal Angle Bar Unqual Angle Bar Structure Steel at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Steel Equal Angle Bar Unqual Angle Bar Structure Steel are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Hot Rolled Steel Equal Angle Bar Unqual Angle Bar Structure Steel are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Specifications of Angle Steel

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

Packaging & Delivery of Angle Steel

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

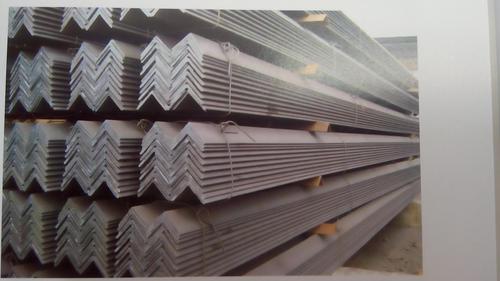

Images:

- Q: How do you determine the required size of a steel angle for a specific application?

- To determine the required size of a steel angle for a specific application, there are several factors that need to be considered. These include the load or weight that the angle will be supporting, the span or distance between supports, and the material properties of the steel angle. Firstly, it is crucial to determine the load or weight that the angle will be subjected to. This can be done by calculating the total load that will be applied to the angle, including the weight of any objects or structures that will be supported by it. It is important to account for both static and dynamic loads, as well as any potential impact or wind loads that may be present. Secondly, the span or distance between supports needs to be considered. This is the length over which the angle will be spanning and supporting the load. Longer spans typically require larger and stronger angles to ensure structural integrity. Additionally, the material properties of the steel angle play a significant role in determining its required size. Steel angles come in various grades and strengths, each with different load-bearing capacities. It is essential to consult engineering and design codes, such as the American Institute of Steel Construction (AISC) Manual, to determine the appropriate grade of steel angle that can withstand the calculated load. Once the load, span, and material properties have been determined, engineering calculations can be performed to select the required size of the steel angle. These calculations typically involve evaluating the moment, shear, and deflection of the angle under the applied load. The AISC Manual provides design tables and equations that can be used to determine the appropriate size and shape of the angle based on these calculations. In conclusion, determining the required size of a steel angle for a specific application involves considering the load, span, and material properties of the angle. By performing engineering calculations and referring to design codes, the appropriate size of the angle can be selected to ensure structural safety and integrity.

- Q: How do you bend steel angles?

- To bend steel angles, you will need to follow a few steps. Firstly, make sure you have the right tools and equipment, such as a bending machine or a bending brake. These tools are specifically designed to bend metal angles accurately and efficiently. Next, measure and mark the desired bending point on the steel angle. Use a ruler or a measuring tape to ensure accurate measurements. It is essential to have precise markings to achieve the desired angle. After marking the bending point, secure the steel angle tightly in the bending machine or brake. This will prevent any movement or slippage during the bending process. Now, carefully position the bending machine or brake to align with the marked bending point. Adjust the bending angle according to your requirements. This can usually be done by adjusting the clamps or handles on the machine. Once everything is properly aligned, apply gradual pressure to the bending machine or brake. Start with a low pressure and gradually increase it until the steel angle starts bending. Be patient and avoid applying excessive force, as this can cause the angle to deform or break. Continue applying pressure until the desired angle is achieved. Use a protractor or angle measuring tool to ensure accuracy. If necessary, make any minor adjustments to the angle by repositioning the steel angle in the bending machine or brake. Once the bending process is complete, carefully remove the steel angle from the bending machine or brake. Inspect the angle for any imperfections or deformities. If there are any issues, you may need to repeat the bending process or make adjustments to your technique. It is important to note that bending steel angles can be challenging, especially if you are not experienced or do not have the right tools. If you are unsure about the process, it is recommended to seek professional assistance or consult with a metal fabrication expert who can guide you through the bending process safely and accurately.

- Q: How do steel angles contribute to the overall safety of a building?

- Angle irons, also known as steel angles, play a vital role in improving the overall safety of a building. These structural elements have unique properties and advantages that make them widely used in construction. To begin with, steel angles contribute to the structural support and stability of a building. They are commonly utilized to reinforce and strengthen the framework, particularly at critical load-bearing points. By distributing and transferring weight and forces, steel angles prevent excessive deflection or deformation of the building, ensuring its integrity and stability, even under heavy loads or adverse conditions. This reinforcement is particularly crucial in tall buildings or structures located in earthquake-prone or high-wind regions. Moreover, steel angles enhance the safety of a building by acting as protective barriers or shields against potential hazards. For instance, they can be installed as guards or handrails on staircases, balconies, or elevated platforms. These barriers play a vital role in preventing accidental falls or injuries, creating a secure environment for occupants. Steel angles can also be utilized to create safety barriers around machinery or equipment, preventing unauthorized access or accidental contact. Additionally, steel angles contribute to enhancing fire resistance in buildings. Steel is inherently fire-resistant and does not contribute to the spread of flames. By incorporating steel angles into the structural design of a building, it becomes possible to effectively support fire-rated walls, partitions, or fireproof doors. This facilitates the compartmentalization of the building, slowing down the spread of fire and allowing occupants more time to evacuate safely. Furthermore, steel angles offer longevity and durability, making them an ideal choice for long-term safety. Steel is highly resistant to corrosion, weathering, and other environmental factors, ensuring the structural integrity of the building over time. This durability reduces the risk of sudden structural failures or collapses, thereby enhancing overall safety for occupants and nearby structures. In conclusion, steel angles play a significant role in improving the overall safety of a building. Their ability to provide structural support, act as barriers, enhance fire resistance, and offer durability make them crucial components for ensuring the stability and protection of a structure and its occupants.

- Q: Are there any environmental concerns associated with steel angles?

- Steel angles are associated with various environmental concerns. The production process involves extracting iron ore, mining coal for coke production, and emitting greenhouse gases during steelmaking. These activities contribute to deforestation, air pollution, and climate change. Furthermore, disposing of steel angles at the end of their life cycle can be problematic. Steel is not biodegradable and can take hundreds of years to decompose in landfills. Improper disposal can contaminate soil and water, posing risks to ecosystems and human health. Moreover, transporting steel angles from production facilities to construction sites can lead to carbon emissions and air pollution. The energy needed for transportation increases the overall environmental impact. To address these concerns, several strategies can be implemented. Firstly, using recycled steel instead of virgin steel significantly reduces the environmental footprint. Additionally, employing energy-efficient technologies in the production process can minimize greenhouse gas emissions. Lastly, responsibly disposing and recycling steel angles at the end of their life cycle helps reduce the environmental impact.

- Q: Are steel angles suitable for manufacturing shelving units?

- Absolutely, steel angles are absolutely fitting for the production of shelving units. Steel angles offer exceptional structural support and stability, rendering them an optimal selection for shelving systems. They possess the capability to endure substantial loads and evenly distribute weight, guaranteeing the sturdiness and endurance of the shelving units. Additionally, steel angles are user-friendly and can be customized to suit specific dimensions and designs. They also have resistance against corrosion and can withstand demanding environmental conditions, making them suitable for both indoor and outdoor shelving units. All in all, steel angles provide the strength, versatility, and dependability required for the production of top-notch and enduring shelving units.

- Q: Can steel angles be used for staircases or handrails?

- Yes, steel angles can be used for staircases or handrails. Steel angles provide structural support and can be used to create sturdy and durable staircases and handrails. They are commonly used in construction for their strength and versatility.

- Q: How do you determine the required thickness of a steel angle for a specific application?

- To determine the required thickness of a steel angle for a specific application, several factors need to be considered. Firstly, it is essential to determine the load or weight that the steel angle will be subjected to. This includes both the dead load (the weight of the steel angle itself) as well as any live loads (external forces or loads applied to the angle). Next, the span or distance between supports needs to be determined. The greater the span, the higher the bending moment and deflection that the steel angle will experience. Once the load and span are known, it is necessary to calculate the maximum allowable stress or bending moment that the steel angle can withstand. This is typically done using engineering formulas or structural analysis software. The maximum allowable stress is determined based on the steel's yield strength and safety factors. Using the maximum allowable stress and the bending moment, the required section modulus of the steel angle can be calculated. The section modulus is a measure of the angle's resistance to bending and is directly related to its thickness. Finally, the required thickness of the steel angle can be determined by selecting a standard angle size that has a section modulus equal to or greater than the calculated value. It is crucial to note that other considerations, such as corrosion protection, fire resistance, and aesthetics, may also influence the selection of the steel angle thickness. Therefore, consulting structural engineers or following relevant building codes and standards is highly recommended to ensure the safety and performance of the steel angle in a specific application.

- Q: Can steel angles be used in temporary or modular structures?

- Indeed, temporary or modular structures can make use of steel angles. These angles are frequently employed in construction owing to their strength, adaptability, and affordability. Their primary function is to offer structural support and stability in a wide array of applications, including temporary or modular structures. The versatility of steel angles lies in their ease of cutting, welding, and bolting, allowing for convenient assembly and disassembly of such structures. Furthermore, steel angles possess the ability to endure substantial loads and provide exceptional resistance against bending and twisting forces, guaranteeing the stability and safety of the structure.

- Q: Can steel angles be used for solar panel mounting?

- Yes, steel angles can be used for solar panel mounting. Steel angles provide a sturdy and durable framework to securely mount solar panels, ensuring stability and longevity in various weather conditions.

- Q: How do you calculate the deflection of a loaded steel angle?

- In order to determine the deflection of a loaded steel angle, several factors must be considered and the principles of structural engineering must be applied. Here is a step-by-step guide on how to accomplish this: 1. Find out the load: Begin by obtaining information about the magnitude and distribution of the load that is applied to the steel angle. This load can be a point load, a uniformly distributed load, or a combination of both. 2. Identify the properties of the steel angle: Acquire the dimensions and material properties of the steel angle, including its length, width, thickness, and modulus of elasticity (E). The modulus of elasticity represents the stiffness of the material. 3. Determine the support conditions: Evaluate how the steel angle is supported. It may be simply supported at both ends, fixed at one end, or a combination of fixed and simply supported conditions. Different support conditions will lead to different deflection formulas. 4. Choose an appropriate deflection formula: Depending on the load and support conditions, select the relevant deflection formula from a reference source such as a structural engineering handbook. There are various formulas available, including those specifically designed for angles subjected to bending. 5. Input the values: Substitute the known values, such as the magnitude of the load, the dimensions of the angle, and the material properties, into the chosen deflection formula. Ensure that the units are consistent. 6. Solve for deflection: Perform the necessary calculations to determine the deflection of the loaded steel angle. The result will be expressed in units of length, such as inches or millimeters. 7. Verify the deflection: If possible, compare the calculated deflection with the allowable deflection specified in relevant design codes or standards. This will help ensure that the angle does not deflect beyond acceptable limits. Remember, the calculation of the deflection of a loaded steel angle is an engineering task that requires knowledge of structural principles and the use of appropriate formulas. If you are uncertain or dealing with complex situations, it is advisable to consult a professional structural engineer for accurate and reliable calculations.

Send your message to us

Hot Rolled Steel Equal Angle Bar Unqual Angle Bar Structure Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords