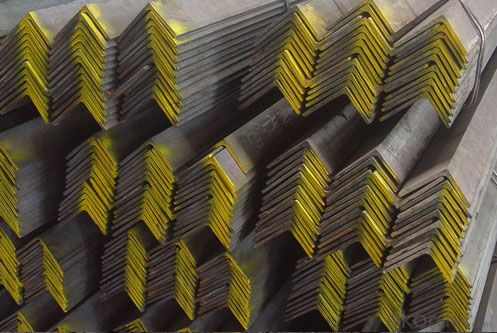

Unequal Angle Steel Famous Style Low Alloy For Profile Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description of Unequal Angle Steel Famous Style Low Alloy For Profile Steel:

OKorder is offering Unequal Angle Steel Famous Style Low Alloy For Profile Steel at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications of Unequal Angle Steel Famous Style Low Alloy For Profile Steel:

Unequal Angle Steel Famous Style Low Alloy For Profile Steel are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages of Unequal Angle Steel Famous Style Low Alloy For Profile Steel:

OKorder'sUnequal Angle Steel Famous Style Low Alloy For Profile Steel are durable, strong, and resist corrosion.

Main Product Features of Unequal Angle Steel Famous Style Low Alloy For Profile Steel:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications of Unequal Angle Steel Famous Style Low Alloy For Profile Steel:

1.Standard: GB,ASTM,JIS

2.Steel Grade:Q195-Q420

3.Length: 5.8-12mm

Unequal Angle Steel Famous Style Low Alloy For Profile Steel

| ||

Thickness | 12mm | |

3mm-25mm | 20mm-200mm | |

Length

| 5.8-12M , according to customers' requirements | |

Standard

| GB,JIS,ASTM,EN,DIN | |

Material

| 304 304L 316 321 | |

Type | Equal and unequal | |

Usage

| constructions,communication towers and so on. | |

Certification

| ISO9001,ISO9002,API | |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays

Advantages of Unequal Angle Steel Famous Style Low Alloy For Profile Steel

1. Convenient in construction and save much time and labor.

2. Light, good quality and reasonable price.

3. The shape and specification can be made by customer's requirement.

4. High mechanical strength.

5. Attractive in appearance and reasonable designs.

- Q: What are the standard sizes of steel angles?

- The standard sizes of steel angles vary, but some common sizes include 1/2 inch, 3/4 inch, 1 inch, 1-1/4 inch, and 1-1/2 inch.

- Q: What are the common standards and specifications for steel angles?

- The common standards and specifications for steel angles include the American Society for Testing and Materials (ASTM) A36/A36M, which covers carbon structural steel shapes, and ASTM A572/A572M, which pertains to high-strength low-alloy structural steel angles. Additionally, the European Norm (EN) 10025-2 specifies the technical delivery conditions for non-alloy structural steels, including angles. These standards define the chemical composition, mechanical properties, and tolerances of steel angles, allowing for consistent quality and compatibility in various construction and engineering applications.

- Q: Can steel angles be used for manufacturing equipment frames?

- Yes, steel angles can be used for manufacturing equipment frames. Steel angles are commonly used in construction and manufacturing due to their strength, durability, and versatility. They provide structural support and stability, making them ideal for designing and constructing equipment frames. Steel angles can be easily welded or bolted together to create a rigid and robust frame structure. Additionally, steel angles can be cut to specific lengths and shapes, allowing for customization and precise assembly. Overall, steel angles are a popular choice for manufacturing equipment frames due to their reliability and cost-effectiveness.

- Q: Can steel angles be used in equipment supports?

- Indeed, equipment supports can utilize steel angles. Owing to their robustness and adaptability, steel angles frequently find application in construction and structural contexts. They serve as dependable supports, braces, and reinforcements for diverse equipment and machinery. Given their capacity to withstand substantial loads, steel angles ensure stability and are thus well-suited for industrial equipment support. Moreover, their malleability and capacity for customization make them highly sought-after for equipment support due to their ability to satisfy specific requirements.

- Q: How much is the weight of 40 * 3 angle steel theory?

- Also available models that model is the number of centimeters wide, such as angle 3#. The model does not mean the size of the different edges and sizes of the same model. Therefore, the width, the edge and the thickness of the angle iron should be filled out in the contract and other documents, so as not to be indicated by the model alone. Standard Specification for hot-rolled equal angle iron is 2#-20#.

- Q: What are the different types of steel angles connections for joists?

- Joists commonly employ several types of steel angle connections. These options include: 1. Welded Connection: The simplest and most prevalent connection involves directly welding the steel angles to the joists. This method provides a sturdy and inflexible connection, albeit requiring skilled labor and additional welding time. 2. Bolted Connection: This connection involves fastening the steel angles to the joists using bolts or screws. It allows for easier installation and disassembly if necessary. However, it may not be as robust as a welded connection and may necessitate periodic bolt tightening. 3. Gusset Plate Connection: A flat steel plate known as a gusset plate connects the steel angles to the joists. Typically, this plate is secured by welding or bolting to both the angles and the joists, enhancing the connection's strength and stability. 4. Clip Angle Connection: L-shaped brackets called clip angles attach to the joists and steel angles using bolts or screws. This method offers a straightforward and efficient means of connecting angles to the joists, with the added benefit of easy adjustment or replacement. 5. Shear Plate Connection: This connection type employs a thick steel plate with holes, known as a shear plate, to link the steel angles to the joists. Like the gusset plate connection, the shear plate is usually welded or bolted to both the angles and the joists, ensuring a robust and secure connection. The selection of a particular steel angle connection method depends on factors such as load requirements, installation ease, and cost considerations, as each option presents its own advantages and disadvantages.

- Q: How do steel angles contribute to the overall stability of a building frame?

- Steel angles contribute to the overall stability of a building frame by providing structural support and reinforcement. They are commonly used as braces and connections in building frames to increase their load-bearing capacity and resist forces such as wind, earthquakes, and heavy loads. The angles help distribute and transfer the loads throughout the structure, enhancing its stability and preventing deformation or collapse.

- Q: How are steel angles inspected for quality and compliance with standards?

- Quality and compliance inspections are conducted on steel angles through a rigorous series of tests and examinations. Qualified personnel, often trained and certified in non-destructive testing (NDT) methods, carry out these inspections. The inspection process begins with a visual examination of the steel angles to identify any surface defects such as cracks, pits, or sharp edges. This examination ensures that the angles are free from visible defects that could compromise their strength and structural integrity. Next, dimensional checks are performed to confirm that the steel angles meet the specified dimensions and tolerances outlined in the applicable standards. This includes measuring the length, width, thickness, and other critical dimensions to ensure they align with the required specifications. To assess the internal soundness of the steel angles, non-destructive testing methods are employed. These methods include ultrasound testing (UT), magnetic particle testing (MT), liquid penetrant testing (PT), and radiographic testing (RT). UT uses high-frequency sound waves to detect internal flaws or discontinuities, while MT and PT involve applying magnetic particles or liquid dyes to detect surface cracks or defects. RT uses X-rays or gamma rays to inspect the internal structure of the steel angles. Mechanical tests are also conducted to evaluate the mechanical properties of the steel angles. These tests may include tensile testing, which measures the strength and elasticity of the material, and hardness testing, which determines the resistance of the steel to indentation or scratching. These tests ensure that the steel angles have the necessary mechanical strength and properties as specified by the standards. Furthermore, chemical analysis is performed to verify the chemical composition of the steel angles, particularly the levels of various alloying elements. This analysis ensures that the steel meets the required chemical composition standards, which directly impact its strength, corrosion resistance, and other properties. In addition to these inspections, steel angles may also undergo surface treatment testing, such as measuring coating thickness, testing adhesion, or conducting salt spray tests, to confirm that any protective coatings or finishes applied meet the required standards. Overall, the inspection process for steel angles is comprehensive and involves a combination of visual examinations, dimensional checks, non-destructive testing, mechanical tests, chemical analysis, and surface treatment testing. These inspections are crucial to ensure that the steel angles meet the necessary quality and compliance standards, instilling confidence in their performance and reliability for various applications.

- Q: Can steel angles be used for equipment racks or shelving?

- Yes, steel angles can be used for equipment racks or shelving. Steel angles are commonly used in construction and industrial applications due to their strength and durability. They provide a sturdy framework for supporting heavy equipment or storing items on shelves.

- Q: How do steel angles perform in terms of thermal expansion and contraction?

- Steel angles have a relatively low coefficient of thermal expansion, which means they expand and contract less compared to other materials when subjected to temperature changes. This property makes steel angles highly stable in terms of thermal expansion and contraction. Consequently, they are widely used in various structural applications where temperature variations are expected. Steel angles provide structural integrity and stability, even in environments with significant temperature fluctuations, making them a reliable choice for construction and engineering projects.

Send your message to us

Unequal Angle Steel Famous Style Low Alloy For Profile Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords