Unequal Angle Steel Carbon steel L profile ASTM Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

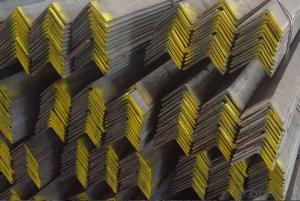

OKorder is offering Unequal Angle Steel Carbon steel L profile ASTM Standard at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Unequal Angle Steel Carbon steel L profile ASTM Standard are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Unequal Angle Steel Carbon steel L profile ASTM Standard are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

Packaging & Delivery of Hot Rolled Unequal Angle Steel

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: How do steel angles perform under seismic loads?

- Steel angles are commonly used in construction to provide structural support and reinforcement. When subjected to seismic loads, steel angles have been found to perform exceptionally well due to their inherent properties and design flexibility. One key advantage of steel angles is their high strength-to-weight ratio. This allows them to withstand the intense forces and movements generated during an earthquake without significant deformation or failure. The compact shape of the angle also helps distribute the load more efficiently, minimizing stress concentrations and potential weak points. Moreover, steel angles can be easily connected to other structural elements, providing a robust and reliable connection system. This is particularly important in seismic design, where the ability to transfer forces and accommodate movements is essential. To further enhance their performance under seismic loads, steel angles can be designed with specific features. For instance, the addition of stiffeners or bracing elements can increase their resistance to lateral forces, reducing the risk of buckling or collapse. Additionally, the use of thicker and stronger steel grades can improve their overall capacity to absorb and dissipate seismic energy. Various seismic design codes and standards provide guidelines and requirements for the use of steel angles in seismic-resistant structures. These codes consider factors such as the maximum allowable stress levels, detailing requirements for connections, and the overall structural behavior under seismic actions. In conclusion, steel angles perform admirably under seismic loads due to their high strength-to-weight ratio, efficient load distribution, and flexibility in design. When properly designed and implemented, steel angles can effectively resist the forces and movements generated during an earthquake, ensuring the structural integrity and safety of the building.

- Q: Are there any special considerations when handling or installing steel angles?

- Yes, there are several special considerations that should be taken into account when handling or installing steel angles. Firstly, it is important to ensure that the angles are stored and transported properly to prevent any damage. Steel angles should be stored in a dry and well-ventilated area to prevent rusting. When transporting, they should be secured properly to prevent any accidents or injuries. Secondly, steel angles should be installed on a solid and level surface to ensure stability and proper load distribution. It is recommended to use a level and plumb line to ensure accurate installation. Thirdly, it is crucial to use the appropriate size and type of fasteners when installing steel angles. The fasteners should be compatible with the angle and the material it is being attached to. It is also important to ensure that the fasteners are tightened properly to avoid any loosening or failure. Additionally, it is important to consider the load-bearing capacity of the steel angles. The angles should be selected based on the expected load and application requirements. It is advisable to consult with a structural engineer or a professional to determine the appropriate size and type of steel angles for the specific project. Lastly, safety precautions should be followed when handling and installing steel angles. Protective gear, such as gloves and safety glasses, should be worn to prevent any injuries. It is also important to follow safe lifting practices and use proper lifting equipment when handling heavy steel angles. Overall, it is important to take these special considerations into account when handling or installing steel angles to ensure proper installation, structural integrity, and safety.

- Q: Do steel angles require maintenance?

- Yes, steel angles do require maintenance. While steel is a durable material, it is still susceptible to rust and corrosion, especially when exposed to moisture or harsh environmental conditions. Regular maintenance is necessary to prevent these issues and ensure the longevity of steel angles. Some common maintenance practices include inspecting for any signs of rust or damage, cleaning the surface to remove dirt and debris, and applying protective coatings or paints to prevent corrosion. Additionally, proper storage and handling of steel angles can also contribute to their maintenance. It is important to follow manufacturer guidelines and consult with professionals to determine the specific maintenance requirements for steel angles in different applications.

- Q: What are the different connection methods for steel angles?

- There are several different connection methods for steel angles, depending on the specific application and structural requirements. Some common connection methods include: 1. Welding: Welding is one of the most common methods used to connect steel angles. It involves melting the adjacent surfaces of the angles and fusing them together using a welding electrode. This method provides high strength and rigidity but requires skilled labor and specialized equipment. 2. Bolting: Bolting is another widely used method for connecting steel angles. It involves fastening the angles together using bolts and nuts. Bolting offers the advantage of being easily adjustable and removable, making it suitable for situations where disassembly may be required. 3. Riveting: Riveting is a traditional method of connecting steel angles. It involves inserting a metal rivet through holes in the angles and then deforming the end to secure it in place. Riveting provides a strong and permanent connection but can be time-consuming and labor-intensive. 4. Adhesive bonding: Adhesive bonding is a modern method of connecting steel angles. It involves applying a high-strength adhesive to the contact surfaces of the angles and then joining them together. This method offers the advantage of being lightweight, flexible, and resistant to corrosion. 5. Mechanical fasteners: There are various mechanical fasteners available for connecting steel angles, such as self-tapping screws, self-drilling screws, and blind rivets. These fasteners provide a quick and easy way to connect angles without the need for additional tools or equipment. It is important to consider factors such as load requirements, structural stability, corrosion resistance, and ease of installation when selecting the appropriate connection method for steel angles.

- Q: What is the meaning of the number of angle steel

- Angle called angle, the steel strip is perpendicular to each other on both sides into the corner. The angle iron can be made up of different force components according to the different structure, and can also be used as the connecting piece between the components.

- Q: What is the maximum allowable torsional lateral-torsional buckling stress for a steel angle?

- The maximum allowable torsional lateral-torsional buckling stress for a steel angle depends on various factors such as the type of steel, its dimensions, and the applicable design codes or standards. Without specific details, it is not possible to provide an accurate numerical value for the maximum allowable stress.

- Q: What are the different methods of joining steel angles?

- There are several methods of joining steel angles, which are commonly used in construction and fabrication projects. These methods include welding, bolting, riveting, and adhesive bonding. 1. Welding: This is the most common and widely used method for joining steel angles. It involves melting the two angles together using heat and adding a filler material, typically in the form of a welding rod or wire, to create a strong and permanent bond. Welding provides excellent strength and integrity to the joint, and it can be done using various techniques such as arc welding, MIG welding, or TIG welding. 2. Bolting: Bolting is another common method of joining steel angles, especially when the joint needs to be versatile and easily disassembled. It involves using bolts, nuts, and washers to connect the angles together. This method provides a strong and rigid connection, and it allows for easy adjustment or removal of the angles if necessary. 3. Riveting: Riveting is a traditional method of joining steel angles that involves the use of rivets. Rivets are cylindrical metal pins that are inserted through holes drilled in the angles and then hammered or pressed to create a permanent connection. While riveting is less commonly used today due to advancements in welding and bolting techniques, it can still be a suitable method for joining steel angles in certain applications. 4. Adhesive Bonding: Adhesive bonding is a method that involves using industrial adhesives to join steel angles together. This method is particularly useful when aesthetics, weight reduction, or vibration dampening are important considerations. Adhesive bonding provides a clean and seamless joint, and it can be an effective alternative to welding or bolting in certain situations. Each method of joining steel angles has its advantages and disadvantages, and the choice of method depends on factors such as the intended use of the joint, the load-bearing requirements, the design specifications, and the available equipment and resources. It is important to carefully consider these factors and consult with experts to determine the most suitable method for a specific application.

- Q: What are steel angles?

- Steel angles are a type of steel structural shape that is commonly used in construction and engineering projects. They are L-shaped beams with two legs of equal or unequal length, forming a 90-degree angle. Steel angles are typically made from hot-rolled steel and can be found in various sizes and thicknesses. These angles are versatile and have a wide range of applications. They are commonly used as framing elements in buildings and bridges, providing support and stability. Steel angles can also be used as reinforcement in concrete structures or as brackets and supports for various equipment and machinery. One of the key advantages of steel angles is their strength and durability. They are designed to withstand heavy loads and provide structural integrity. Additionally, steel angles are resistant to corrosion, making them suitable for outdoor applications and environments with high moisture or chemical exposure. Steel angles are available in different grades, with each grade having specific mechanical properties and characteristics. This allows engineers and designers to choose the appropriate angle based on the requirements of the project. In conclusion, steel angles are essential components in construction and engineering. They provide strength, stability, and versatility in various applications. Whether it is for structural support or reinforcement, steel angles play a crucial role in ensuring the integrity and safety of a wide range of structures.

- Q: How do you calculate the section modulus of a steel angle?

- In order to determine the section modulus of a steel angle, one must possess knowledge regarding the dimensions and properties of the angle. The section modulus serves as a metric for measuring the strength of a structural member, enabling the evaluation of its ability to resist bending. The equation employed to compute the section modulus of a steel angle is as follows: Section Modulus (Z) = (Width of the angle * Height of the angle^2) / 6 Within this equation, the width of the angle denotes the distance between the two legs, whilst the height of the angle represents the length of a single leg. The section modulus is conventionally expressed in cubic inches or cubic centimeters. To compute the section modulus, one must initially measure the width and height of the angle. Subsequently, these measured values are substituted into the equation to ascertain the section modulus. This calculated figure provides an indication of the strength and rigidity of the steel angle, ultimately facilitating its application in structural design and analysis.

- Q: Can steel angles be drilled or cut?

- Yes, steel angles can be drilled or cut using appropriate tools and techniques.

Send your message to us

Unequal Angle Steel Carbon steel L profile ASTM Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords