Unequal Angle Steel with High Quality Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

OKorder is offering Unequal Angle Steel with High Quality Made in China at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Unequal Angle Steel with High Quality Made in China are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Unequal Angle Steel with High Quality Made in China are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Packaging & Delivery ofUnequal Angle Steel with High Quality Made in China:

Packaging Detail: products are packed in bundle and then shipped by container or bulk vessel, deformed bar is usually naked strapping delivery, when storing, please pay attention to moisture proof. The performance of rust will produce adverse effect.

Each bundle weight: 2-3MT, or as required

Payment term: TT or L/C

Delivery Detail: within 45 days after received advanced payment or LC.

Label: to be specified by customer, generally, each bundle has 1-2 labels

Trade terms: FOB, CFR, CIF

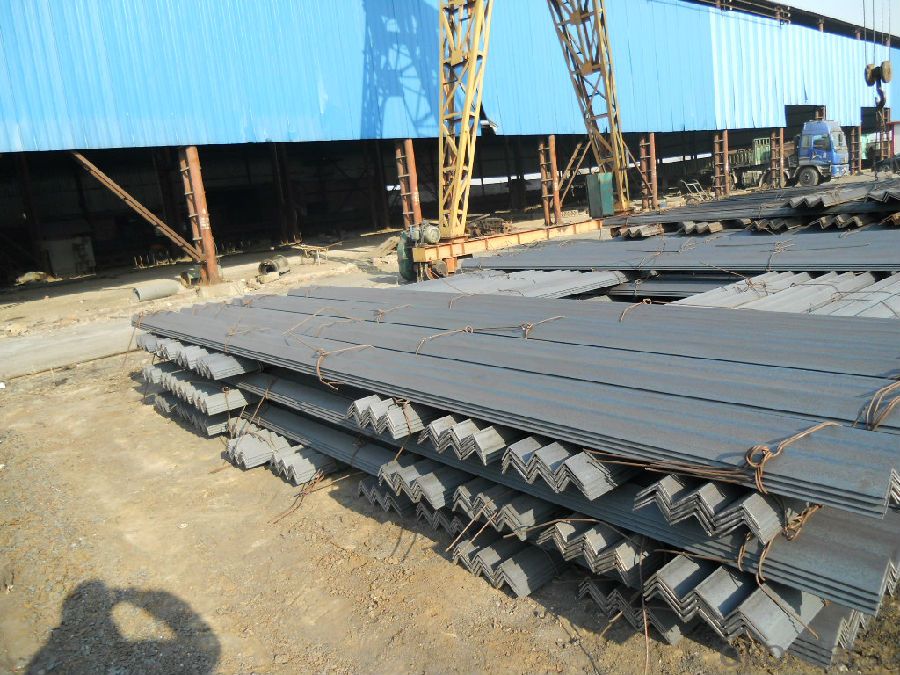

Images:

- Q: What are the different corrosion protection methods for steel angles?

- There exists a range of corrosion protection methods for steel angles, which depend on the particular application and environmental conditions. Some commonly employed methods are as follows: 1. Galvanization: Coating the steel angles with a layer of zinc is a highly effective method of corrosion protection. The zinc layer acts as a sacrificial anode, corroding in place of the underlying steel. 2. Paint coatings: The application of a high-quality paint coating to the steel angles offers effective corrosion protection. The paint acts as a barrier, preventing moisture and corrosive substances from reaching the steel surface. 3. Powder coating: Similar to paint coatings, powder coating involves the application of a dry powder to the steel angles, followed by baking to create a durable and corrosion-resistant finish. 4. Epoxy coatings: For steel angles exposed to harsh environments or aggressive chemicals, epoxy coatings are commonly used. These coatings exhibit excellent adhesion and corrosion resistance. 5. Cathodic protection: This method involves the utilization of a sacrificial anode or impressed current to safeguard the steel angles from corrosion. The anode corrodes instead of the steel, providing long-lasting protection. 6. Barrier coatings: Barrier coatings, such as polyethylene or PVC wraps, create a physical barrier between the steel angles and the surrounding environment. This prevents moisture and corrosive substances from reaching the surface. 7. Hot-dip galvanizing: In this method, the steel angles are immersed in a bath of molten zinc, resulting in the formation of a thick zinc coating that offers superb corrosion protection. When selecting a corrosion protection method for steel angles, it is vital to consider the specific requirements of the application. Factors such as the environment, expected service life, and budget must be taken into account to ensure the most suitable method is chosen.

- Q: How do you prevent steel angles from sagging?

- Steel angles can be prevented from sagging by providing adequate support and reinforcement. This can be achieved by using additional structural steel elements such as beams or columns to provide continuous support along the length of the angle. Additionally, appropriate fastening techniques, such as welding or bolting, should be used to ensure a secure connection between the angle and the supporting structure. Regular inspection and maintenance are also essential to detect any signs of sagging and take necessary corrective measures in a timely manner.

- Q: What are the common corrosion protection methods for steel angles?

- There are several common corrosion protection methods for steel angles. These methods aim to prevent or slow down the process of corrosion, which occurs when steel is exposed to moisture or certain chemicals in its environment. Here are some of the most widely used corrosion protection methods for steel angles: 1. Galvanization: This is a popular method that involves coating the steel angle with a layer of zinc. The zinc acts as a sacrificial anode, meaning it corrodes instead of the steel when exposed to moisture or chemicals. Galvanization provides excellent protection against corrosion and can significantly extend the lifespan of steel angles. 2. Painting: Applying a coat of paint to the steel angle can act as a barrier between the metal and its environment, preventing moisture and chemicals from reaching the surface. However, it is important to choose the right type of paint that is specifically designed for corrosion protection and to ensure proper surface preparation before painting. 3. Powder coating: This method involves applying a dry powder to the steel angle, which is then heated and cured to create a durable and protective coating. Powder coating provides excellent corrosion resistance and is often used in outdoor applications. 4. Epoxy coating: Epoxy coatings are commonly used in corrosive environments such as chemical plants or marine applications. These coatings are highly resistant to chemicals and provide a protective barrier against corrosion. 5. Cathodic protection: This method involves making the steel angle the cathode in a galvanic cell, where a sacrificial anode is connected to the steel angle. This creates an electrochemical reaction that prevents corrosion. Cathodic protection is often used in structures such as underground pipelines or offshore platforms. It is important to note that the choice of corrosion protection method depends on various factors such as the specific environment in which the steel angles will be used, the expected service life, and the budget. Consulting with corrosion protection experts or engineers can help determine the most suitable method for a particular application.

- Q: Can steel angles be used in outdoor or exposed applications?

- Steel angles can indeed be utilized in outdoor or exposed settings. Typically, they are crafted from galvanized steel, which is covered with a protective zinc layer. This zinc coating aids in averting corrosion and rust, rendering them fitting for outdoor purposes. Moreover, steel angles possess robustness and sturdiness, making them appropriate for a range of applications including construction, infrastructure, and outdoor furnishings. Nonetheless, it is crucial to carry out regular maintenance and inspections to detect any indications of corrosion or harm, taking appropriate measures to forestall possible problems.

- Q: What are the environmental benefits of using steel angles?

- The environmental benefits of using steel angles include their high strength and durability, which allows for longer lifespan and reduced need for replacement. Steel angles are also recyclable, contributing to a circular economy by reducing the demand for raw materials and energy consumption. Furthermore, steel angles can be manufactured using recycled steel, reducing the carbon footprint and promoting sustainable practices in the construction industry.

- Q: How do steel angles perform in terms of impact resistance?

- Steel angles have a strong performance when it comes to resisting impacts. Their structural design allows them to withstand high impact forces and distribute them evenly along their length. This quality makes them suitable for various applications, including construction, industrial machinery, and automotive frames, where impacts or dynamic loads are expected. The excellent impact resistance of steel stems from its high strength and toughness. Steel angles are typically made from low carbon steel or alloy steel, both known for their high tensile strength and ability to absorb energy without breaking. As a result, steel angles can resist deformation and maintain their structural integrity even under heavy impacts. Furthermore, the impact resistance of steel angles can be further enhanced by using specific steel grades or applying surface treatments like galvanization or powder coating. These treatments not only improve the corrosion resistance of steel angles but also enhance their overall durability, making them even more resistant to impacts and harsh environmental conditions. However, it is essential to note that the impact resistance of steel angles can vary depending on factors like dimensions, thickness, and material properties. Therefore, it is recommended to consult with a structural engineer or refer to technical specifications provided by manufacturers to ensure that the chosen steel angle is suitable for the intended application and expected impact loads.

- Q: What is the purpose of using steel angles in construction?

- The purpose of using steel angles in construction is to provide structural support and stability. Steel angles are commonly used to reinforce corners, edges, and joints, ensuring the strength and rigidity of the overall structure. They help distribute the load evenly and resist torsional forces, making them essential for the construction of beams, frames, and various structural components.

- Q: Are steel angles suitable for manufacturing support brackets for conduits?

- Steel angles are indeed a suitable choice for the production of support brackets for conduits. In the realms of construction and manufacturing, steel angles are widely employed owing to their robustness and resilience. They offer exceptional structural reinforcement and possess the ability to endure substantial loads. Utilizing steel angles in the creation of support brackets for conduits guarantees the secure and steadfast positioning of said conduits, thereby averting any prospective harm or mishaps. Furthermore, steel angles can be readily tailored to meet particular criteria, including dimensions, configurations, and surface treatments, rendering them an adaptable option for the fabrication of support brackets for conduits.

- Q: How are steel angles welded or joined together?

- Different welding techniques are commonly employed to weld or join steel angles. The prevalent method involves the use of arc welding, which encompasses shielded metal arc welding (SMAW), gas metal arc welding (GMAW), and flux-cored arc welding (FCAW). In shielded metal arc welding, an electric arc is established between a coated electrode and the steel angle. This causes the metals to melt and creates a weld joint. Gas metal arc welding, on the other hand, utilizes a continuous wire electrode and a shielding gas like argon or a combination of argon and carbon dioxide. This shielding gas safeguards the weld from atmospheric impurities. Flux-cored arc welding employs a hollow wire electrode containing flux. This generates a shielding gas and slag that protect the weld. Resistance welding is another technique used for joining steel angles. It involves the application of pressure and the passage of an electric current through the joint area. This generates heat, resulting in a weld. Spot welding and seam welding are commonly employed resistance welding methods for steel angles. Furthermore, steel angles can be joined using stud welding. This process entails placing a threaded or unthreaded stud against the steel angle and utilizing an arc welding process to fuse the stud to the angle. It should be noted that the choice of welding or joining method for steel angles depends on factors such as the thickness and type of steel, the desired joint strength, and the specific requirements of the application.

- Q: What are the different types of steel angles used in automotive engineering?

- Automotive engineering relies on various types of steel angles for structural strength, stability improvement, and overall vehicle performance and safety. Below are some examples of the steel angles frequently employed in this field: 1. Unequal angles, also known as L-angles, provide essential support and reinforcement in automotive engineering. These angles possess different lengths on each side, facilitating easy welding or bolting onto various vehicle chassis or frame components. 2. Tee angles, or T-angles, are commonly used to join two components at a right angle. Their flat base and vertical stem design ensures stability and secure attachment of different vehicle parts. 3. Channel angles, or C-angles, play a significant role in forming vehicle structures. With their U-shaped cross-section, they are often utilized in the creation of structural components like door frames, roof rails, and chassis reinforcements. 4. Z-bar angles, or Z-angles, are widely applied to enhance strength and rigidity in automotive structures. Their Z-shaped cross-section effectively resists bending and torsional forces, making them suitable for suspension systems, roll bars, and body components. 5. U-bar angles, or U-angles, offer support and reinforcement to various vehicle components. Their U-shaped cross-section is frequently employed in the creation of bumper beams, frame reinforcements, and roll cage bars. These examples highlight the diverse applications of steel angles in automotive engineering. Each angle possesses unique properties and is selected based on the vehicle design requirements and desired structural integrity.

Send your message to us

Unequal Angle Steel with High Quality Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords