Ucraine Turkish Deformed Steel Rebars

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 130 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

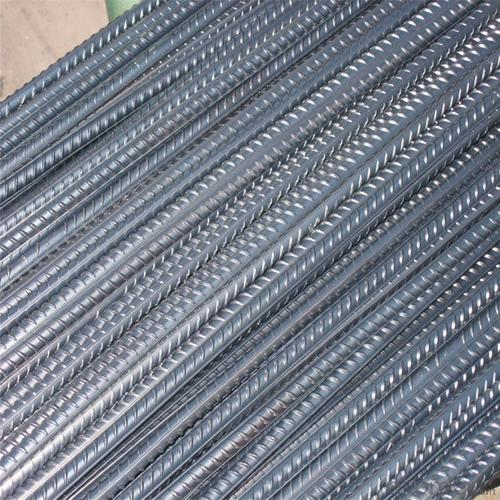

Ucraine Turkish Deformed Steel Rebars

Description of Ucraine Turkish Deformed Steel Rebars

1, Diameter: 5.5mm-10mm Ucraine Turkish Deformed Steel Rebars

10m- 40mm Ucraine Turkish Deformed Steel Rebars

2, Length: 6m, 9m, 12m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

Chemical Composition of Ucraine Turkish Deformed Steel Rebars

Grade | Technical data of the original chemical composition(%) | |||||

Reinforcing steel bar HRB335 | C | Mn | Si | S | P | B |

≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | >0.0008 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 335 | ≥490 | ≥16 | ||||

Reinforcing steel bar HRB400 | C | Mn | Si | S | P | B |

≤0.25 | ≤0.16 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 400 | ≥ 570 | ≥ 14 | ||||

Products Show of Ucraine Turkish Deformed Steel Rebars

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: How does special steel contribute to the renewable energy industry?

- Special steel plays a crucial role in the renewable energy industry by providing the necessary strength, durability, and resistance to extreme conditions for various applications. It is used in wind turbines, solar panels, and hydroelectric infrastructure, enabling the efficient and reliable generation of renewable energy. Special steel also helps enhance the performance, efficiency, and lifespan of these renewable energy systems, ultimately contributing to the sustainability and growth of the industry.

- Q: Can special steel be used in the nuclear power industry?

- Yes, special steel can be used in the nuclear power industry. Special steel is often used for components such as reactor pressure vessels, steam generators, and fuel cladding in nuclear power plants. Special steel's high strength, resistance to corrosion, and ability to withstand high temperatures make it suitable for the demanding conditions and safety requirements of the nuclear power industry.

- Q: How does precipitation-hardening steel achieve high strength through heat treatment?

- Precipitation-hardening steel achieves high strength through heat treatment by a process called aging. After the steel is initially heat-treated, it is cooled quickly to form a supersaturated solid solution. This solution contains a high concentration of alloying elements. When the steel is reheated to a lower temperature, these alloying elements precipitate out, forming small particles within the steel matrix. These precipitates act as obstacles to dislocation movement, which in turn increases the strength of the steel. The size, distribution, and density of these precipitates can be controlled through the heat treatment process, allowing for the desired strength and hardness to be achieved in the final product.

- Q: What are the properties of corrosion-resistant steel?

- Corrosion-resistant steel, also known as stainless steel, possesses several key properties. Firstly, it has a high resistance to corrosion, making it suitable for use in environments with exposure to moisture or corrosive substances. Secondly, it contains a minimum of 10.5% chromium, which forms a protective layer called chromium oxide on the surface, preventing further corrosion. Additionally, it has a strong resistance to staining, which makes it easy to clean and maintain. Moreover, corrosion-resistant steel exhibits excellent strength and durability, making it suitable for a wide range of applications in various industries.

- Q: How does special steel behave under different types of loading conditions?

- Special steel behaves differently under different types of loading conditions. When subjected to tension, it stretches and elongates, but still maintains its strength. Under compression, it can withstand high pressures without deformation. Special steel also exhibits excellent resistance to bending, allowing it to maintain its shape under bending loads. Furthermore, it has high fatigue strength, making it suitable for applications involving cyclic or repetitive loading. Overall, special steel demonstrates superior mechanical properties and performance under various loading conditions.

- Q: How is special steel used in the mining manufacturing process?

- Special steel is commonly used in the mining manufacturing process for various applications. It is used to make durable and strong components such as drill bits, cutting tools, conveyor belts, and machinery parts. Special steel's superior strength, hardness, and resistance to wear and corrosion make it ideal for handling the harsh conditions and heavy loads encountered in mining operations. Additionally, special steel is also employed in the construction of mining equipment, support structures, and infrastructure to ensure reliability and longevity in the demanding mining environment.

- Q: How is carbon steel used in the manufacturing of pipes and tubes?

- Carbon steel is commonly used in the manufacturing of pipes and tubes due to its durability, strength, and cost-effectiveness. It is a versatile material that can withstand high temperatures and pressures, making it suitable for various applications such as oil and gas pipelines, water distribution systems, and structural supports. Additionally, carbon steel can be easily welded and fabricated, allowing for efficient production and customization of pipes and tubes to meet specific requirements.

- Q: What are the specific requirements for special steel used in the defense sector?

- Due to the critical nature of its applications, the defense sector imposes highly demanding requirements on special steel. These requirements encompass: 1. Exceptional strength and durability: Special steel utilized in the defense sector must possess outstanding strength and durability to withstand extreme conditions and endure wear and tear. It should have the capacity to endure high levels of stress, impact, and pressure. 2. Superior corrosion resistance: Defense equipment frequently operates in harsh environments and is exposed to elements that can cause corrosion. Consequently, special steel employed in the defense sector must display excellent corrosion resistance properties to ensure the equipment's longevity and reliability. 3. Heat resistance: Defense applications often involve exposure to high temperatures, such as in jet engines or armored vehicle components. Special steel used in these sectors must retain its strength and structural integrity even at elevated temperatures. 4. Machinability and weldability: Special steel employed in the defense sector should possess favorable machinability and weldability characteristics to facilitate manufacturing and assembly processes. This allows for ease of fabrication, repair, and maintenance of defense equipment. 5. Hardness and toughness: Defense applications necessitate a combination of hardness and toughness in special steel. It must resist penetration and deformation while simultaneously being able to absorb energy and resist fracture. 6. Non-magnetic properties: In specific defense applications, such as submarines and magnetic resonance imaging (MRI) equipment, non-magnetic properties are essential. Special steel employed in these sectors must possess low magnetic permeability to prevent interference with sensitive electronic systems. 7. Certification and compliance: Special steel used in the defense sector must meet specific certification and compliance standards, such as those established by defense organizations or international quality management systems like ISO 9001. These standards guarantee the quality, traceability, and reliability of the steel. Meeting these specific requirements for special steel utilized in the defense sector is crucial to ensure the safety, effectiveness, and longevity of defense equipment and systems. Rigorous testing and quality control processes are implemented to ensure that the steel meets the required specifications and standards.

- Q: How does special steel contribute to improving product efficiency in energy-intensive processes?

- Special steel plays a crucial role in enhancing product efficiency in energy-intensive processes by offering superior strength, durability, and heat resistance. It allows for the design and construction of lighter, more compact equipment, reducing energy consumption and improving overall efficiency. Additionally, special steel's corrosion resistance properties help extend the lifespan of machinery, minimizing downtime and maintenance costs. Its use in energy-intensive processes enables better performance, optimized resource utilization, and ultimately contributes to a greener and more sustainable industrial landscape.

- Q: How does special steel contribute to the strength of structures?

- Special steel contributes to the strength of structures through its unique properties and composition. It is specifically engineered to have higher tensile strength, durability, and resistance to corrosion compared to regular steel. Its increased strength allows structures to withstand heavier loads, vibrations, and extreme weather conditions more effectively, ensuring their stability and longevity. Additionally, the use of special steel enables the construction of lighter and more streamlined structures, as thinner sections can be used without compromising their strength. Overall, special steel plays a vital role in enhancing the structural integrity and safety of various buildings, bridges, and infrastructure projects.

Send your message to us

Ucraine Turkish Deformed Steel Rebars

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 130 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords