M2 Steel Flat Bar for Tool Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

M2 Steel Flat Bar for Tool Steel

Product description:

Size of M2 high speed steel | |||||||||

Round bar | Diameter(mm) | Length (mm) | |||||||

Max:800 | Max: 9000 | ||||||||

Plate | Thickness(mm) | Width (mm) | Length (mm) | ||||||

Max:800 | Max:1000 | Max:6000 | |||||||

The specification can be customized. | |||||||||

Chemical Compositons | |||||||||

Grade | C | Si | Mn | P | S | Cr | Mo | W | V |

W6o5Cr4V | 0.80-0.90 | 0.20-0.45 | 0.15-0.40 | ≤0.03 | ≤0.03 | 3.80-4.40 | 4.50-5.50 | 5.50-6.75 | 1.75-2.20 |

M2 | 0.78-0.88 | 0.20-0.45 | 0.15-0.45 | ≤0.03 | ≤0.03 | 3.75-4.50 | 4.50-5.50 | 5.50-6.75 | 1.75-2.20 |

1.3343 | 0.80-0.88 | ≤0.45 | ≤0.40 | ≤0.03 | ≤0.03 | 3.80-4.50 | 4.70-5.20 | 5.90-6.70 | 1.70-2.10 |

SKH51 | 0.80-0.88 | ≤0.45 | ≤0.40 | ≤0.03 | ≤0.03 | 3.80-4.50 | 4.70-5.20 | 5.90-6.70 | 1.70-2.10 |

Features of M2 high speed steel

1, General purpose of tungsten molybdenum high speed steel; | |||||||||

2, High toughness combined with good cutting powers; | |||||||||

3, Will withstand increases in temperature. |

Typical Applications:

1, Twist drills, reamers, broaching tools, taps, milling tools; | |||||||||

2, Cold forming tools and cutting tools; | |||||||||

3, Plastic moulds with elevated wear resistance and screws.

Packing: silver bright steel packaging : coated with anti-rust oil -plastic film winding -woven cloth winding- -strip steel strapping-wood shipping:according to contract content

|

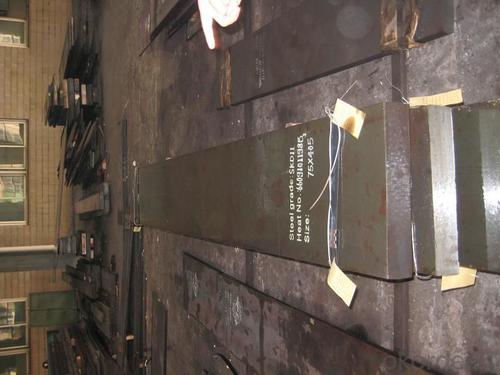

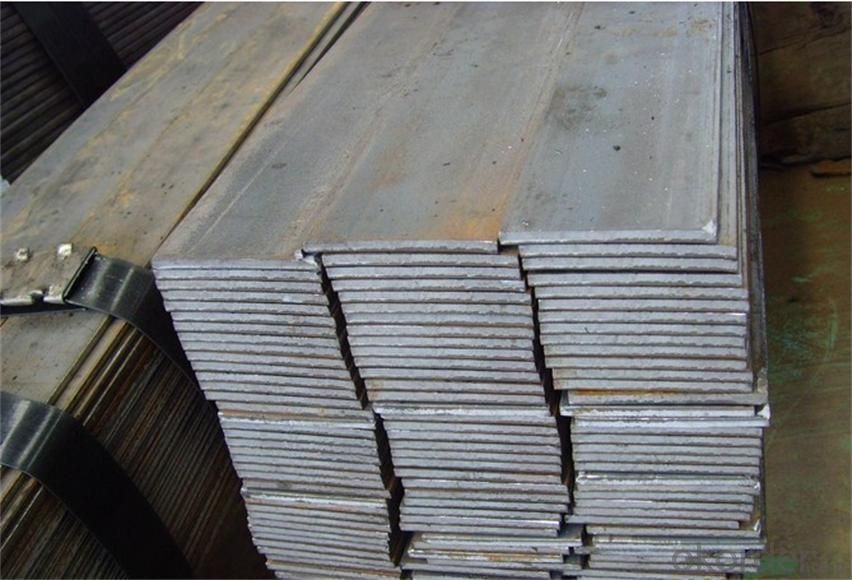

Products show:

- Q: Can special steel be cast?

- Yes, special steel can be cast. Castings of special steel are produced using various casting methods such as investment casting, sand casting, or continuous casting, depending on the specific requirements and properties of the steel.

- Q: How is high-temperature steel used in power generation equipment?

- High-temperature steel is commonly used in power generation equipment due to its excellent heat resistance properties. It is utilized in the manufacturing of boilers, turbines, and heat exchangers, where it can withstand extreme temperatures and pressures. This steel variant helps increase the efficiency and reliability of power plants by withstanding the intense heat generated during power generation processes.

- Q: How does special steel contribute to the manufacturing of oil and gas equipment?

- Special steel plays a crucial role in the manufacturing of oil and gas equipment due to its unique properties and characteristics that make it suitable for the demanding conditions of the industry. Firstly, special steel is known for its high strength and durability, which is essential in the production of oil and gas equipment. Equipment such as drilling rigs, pipelines, and storage tanks are subjected to extreme pressures, corrosive environments, and harsh weather conditions. Special steel, with its superior mechanical properties, can withstand these conditions and ensure the reliable and long-lasting performance of the equipment. Additionally, special steel offers excellent resistance to corrosion and oxidation, which are prevalent in the oil and gas industry. The presence of corrosive substances and the exposure to high temperatures can cause regular steel to deteriorate quickly. However, special steel is specifically designed to resist corrosion, ensuring that the equipment remains functional and safe for use over its lifetime. Furthermore, special steel can withstand high temperatures and pressure differentials, making it suitable for applications such as heat exchangers and pressure vessels. These components are vital in various oil and gas processes, including refining and transportation. The ability of special steel to handle extreme temperatures and pressures ensures the efficiency and safety of these operations. Special steel also contributes to the manufacturing of oil and gas equipment by providing excellent weldability and machinability. This allows for ease of fabrication and assembly, reducing production time and costs. The versatility of special steel enables manufacturers to design and create complex equipment that meets the specific requirements of the oil and gas industry. In conclusion, special steel plays a crucial role in the manufacturing of oil and gas equipment by providing high strength, durability, corrosion resistance, and the ability to withstand extreme temperatures and pressures. Its unique properties ensure the reliability, safety, and longevity of the equipment, making it an indispensable material in the oil and gas industry.

- Q: What are the different methods of preventing pitting corrosion in special steel?

- Various methods exist to prevent pitting corrosion in special steel. The objective of these techniques is to safeguard the steel surface from the harmful effects of its environment and hinder the development of pits. Some commonly used methods include: 1. Passivation: Passivation entails treating the steel surface with a chemical solution or coating to generate a protective oxide layer. This layer functions as a barrier, obstructing the infiltration of corrosive agents and minimizing the risk of pitting corrosion. 2. Alloying: By incorporating specific alloying elements into the steel composition, its resistance to corrosion can be enhanced. Elements like chromium, nickel, and molybdenum are frequently utilized as they augment the steel's capacity to form a stable passive film and withstand pitting corrosion. 3. Cathodic protection: This technique involves either utilizing a sacrificial anode or employing an impressed current on the steel surface. By making the steel cathodic, it becomes less prone to corrosion as electrons are drawn away from it, thus preventing pit formation. 4. Coatings: Applying a protective coating to the steel surface can effectively deter pitting corrosion. Coatings such as paint, epoxy, or polymer-based materials serve as physical barriers, shielding the steel against corrosive agents. 5. Environmental control: Regulating the surrounding environment of the steel can also assist in preventing pitting corrosion. This encompasses measures like controlling temperature, humidity, and pH levels to ensure they remain within acceptable limits, thereby inhibiting the corrosion process. 6. Regular maintenance: Consistent inspection and maintenance of the steel surface are vital in preventing pitting corrosion. Any signs of damage or deterioration should be promptly addressed to prevent further corrosion and potential pitting. It should be noted that the choice of prevention method relies on various factors such as the specific steel composition, the corrosive environment, and the intended application. Proper selection and implementation of these methods can significantly enhance the resilience of special steel to pitting corrosion, guaranteeing its longevity and performance.

- Q: What are the factors affecting the cost of special steel?

- There are several factors that can affect the cost of special steel. Firstly, the cost of raw materials used in the production of special steel, such as iron ore and alloys, can have a significant impact on its overall price. Additionally, the level of demand for special steel, both domestically and globally, can influence its cost. Factors such as market competition, economic conditions, and government policies can also play a role in determining the price of special steel. Lastly, the complexity of the manufacturing process, including the level of skill required and the use of advanced technologies, can contribute to the higher cost of special steel compared to regular steel.

- Q: What are the main applications of special steel in the semiconductor industry?

- Special steel is widely used in the semiconductor industry for various applications. One of the main applications is in the manufacturing of wafer handling components such as vacuum chucks, reticle stages, and load ports. Special steel's high strength, corrosion resistance, and precision machining capabilities make it ideal for these critical components that require excellent dimensional stability and reliability. Additionally, special steel is also used in the construction of cleanroom equipment, such as gas cabinets, exhaust systems, and process tools, where its resistance to chemical and thermal stress is highly valued. Overall, special steel plays a crucial role in ensuring the efficiency, accuracy, and safety of semiconductor manufacturing processes.

- Q: What are the different forms of special steel?

- There are several different forms of special steel, including stainless steel, tool steel, high-speed steel, alloy steel, and spring steel. Each form has unique properties and is designed for specific applications in various industries.

- Q: How does special steel contribute to improving product durability?

- Special steel contributes to improving product durability in several ways. Firstly, special steel has superior strength and toughness compared to regular steel, making it more resistant to wear and tear. This allows products made from special steel to withstand heavy usage and harsh conditions without losing their structural integrity. Additionally, special steel is often more corrosion-resistant, preventing rust and other forms of deterioration that can compromise a product's longevity. Lastly, special steel can be tailored to specific applications, enabling manufacturers to design products with optimal performance and durability in mind. Overall, special steel plays a crucial role in enhancing product durability and extending their lifespan.

- Q: How does molybdenum improve the performance of special steel?

- Molybdenum plays a crucial role in enhancing the performance of special steel due to its unique properties and characteristics. First and foremost, molybdenum significantly improves the strength and toughness of steel, making it more durable and resistant to deformation. This is achieved by forming a solid solution with iron, which results in a fine-grained microstructure and reduces the formation of brittle phases in the steel. Moreover, molybdenum increases the hardenability of steel, allowing it to be heat-treated to obtain desired mechanical properties. This is particularly important in the production of special steel, where high strength, wear resistance, and thermal stability are often required. By enabling effective heat treatment, molybdenum ensures that the steel can be processed to meet specific performance requirements, such as hardness, toughness, and dimensional stability. Additionally, molybdenum enhances the corrosion resistance of special steel, making it suitable for various challenging environments. It forms a protective oxide layer on the surface of the steel, which acts as a barrier against corrosive substances like acids, alkalis, and salts. This resistance to corrosion is crucial in applications where the steel is exposed to harsh conditions, such as marine environments, chemical processing plants, and oil and gas industries. Furthermore, molybdenum improves the high-temperature strength and creep resistance of special steel. It enables the steel to maintain its mechanical properties even at elevated temperatures, making it suitable for applications where the steel is subject to prolonged exposure to heat or mechanical stress. In summary, molybdenum plays a vital role in enhancing the performance of special steel by improving its strength, toughness, hardenability, corrosion resistance, and high-temperature properties. These attributes make molybdenum an essential alloying element in the production of special steel for various industries, including automotive, aerospace, energy, and tool manufacturing.

- Q: How does special steel contribute to the manufacturing of precision instruments?

- Special steel plays a crucial role in the manufacturing of precision instruments. Its unique characteristics and properties make it an ideal material choice for these applications. Firstly, special steel offers exceptional strength and durability, allowing precision instruments to withstand extreme conditions, heavy loads, and repetitive use. This ensures the longevity and reliability of these instruments, which is vital in critical industries such as aerospace, automotive, and medical. Moreover, special steel has excellent corrosion resistance, preventing the instruments from deteriorating over time. This is especially important for precision instruments that are exposed to various elements, chemicals, or moisture during their operation or storage. Special steel also provides high thermal stability, enabling precision instruments to maintain their accuracy in different temperature environments. This is vital for instruments that are used in industries where temperature fluctuations can affect their performance, such as laboratories or manufacturing plants. Additionally, special steel can be customized and tailored to meet specific design requirements. It can be easily machined, formed, or welded into intricate shapes and parts, allowing manufacturers to create precision instruments with complex geometries and tight tolerances. This level of precision is crucial for instruments used in fields like metrology, microscopy, or nanotechnology. Furthermore, special steel offers excellent magnetic properties, which can be advantageous for precision instruments that rely on magnetic fields for their operation. This includes instruments like magnetic resonance imaging (MRI) machines, compasses, or magnetometers. In conclusion, special steel contributes significantly to the manufacturing of precision instruments by providing strength, durability, corrosion resistance, thermal stability, customization options, and magnetic properties. These characteristics ensure the performance, accuracy, and longevity of precision instruments, making them indispensable in various industries.

Send your message to us

M2 Steel Flat Bar for Tool Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords