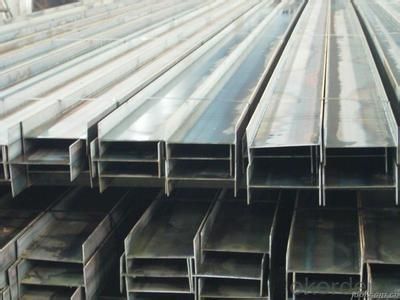

U Channel Steel/Steel Channel Iron/Galvanized Steel Channel Dimensions

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 40000 PCS/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

U Channel Steel/Steel Channel Iron/Galvanized Steel Channel Dimensions Details

| Dimensions: | 5#-40#AB | Grade: | Q235,Q345/SS400, SM400A,SM400B | Place of Origin: | China (Mainland) |

| Certificate: | CQC | Model Number: | 5#-40# | Shape: | U Channel |

| Application: | manufacture and fabrication of a broad range of engineered products | Perforated Or Not: | Not Perforated | Standard: | GB,JIS,EN |

Packaging & Delivery

| Packaging Detail: | Standard export packing or as per your request |

| Delivery Detail: | 25-45 days |

U Channel Steel/Steel Channel Iron/Galvanized Steel Channel Dimensions Advantages

Full size

High quality

Prompt shipment

U Channel Steel/Steel Channel Iron/Galvanized Steel Channel Dimensions Specifications

Product | U channel steel | ||

| Standard | JIS AISI ASTM GB DIN BS | ||

| Grade | Q235,Q345/SS400,SM400A,SM400B,SPFC590 | ||

| Size | 50*37*4.5mm---400*104*14.5mm | ||

| Length | 6m,9m,12m,or cut the goods to the clients'request | ||

| Shape | U | ||

| Package | Standard export packing or as per your request | ||

| Application | Construction,shipbuilding,machine-made household industry | ||

U Channel Steel/Steel Channel Iron/Galvanized Steel Channel Dimensions Pictures

- Q: Can steel channels be used in electrical applications?

- Yes, steel channels can be used in electrical applications. Steel channels are often used in electrical installations to provide support and protection for electrical cables and wiring. They are commonly used in industrial and commercial settings where durability and strength are important. Steel channels are typically made from galvanized steel, which provides corrosion resistance and ensures a long lifespan. They can be easily installed and provide a stable and secure pathway for electrical cables, helping to prevent damage and maintain a neat and organized wiring system. Additionally, steel channels can be used to mount electrical equipment and components, such as junction boxes or conduits, allowing for easy access and maintenance. Overall, steel channels are a reliable and versatile option for electrical applications.

- Q: Are steel channels suitable for supporting overhead equipment or structures?

- Indeed, steel channels prove to be a fitting choice when it comes to supporting overhead equipment or structures. Their strength and durability make them a common choice in construction and engineering endeavors. By offering a secure and dependable support system, steel channels ensure safety and stability. These channels are specifically designed to bear heavy loads, making them an ideal option for supporting equipment or structures that demand a robust and steadfast foundation. Moreover, steel channels can be tailored to meet precise project specifications, encompassing size, shape, and length, further amplifying their appropriateness in supporting overhead equipment or structures.

- Q: What are the different types of steel channel connections?

- Construction and structural engineering commonly employ various types of steel channel connections. Some frequently used ones include: 1. Welded connections: The most prevalent steel channel connection involves welding the ends of multiple channels together, ensuring a robust and enduring connection. Welded connections find application where the channel load is relatively low and adjustability is unnecessary. 2. Bolted connections: For higher channel loads and the need for adjustability or removability, bolted connections come into play. Bolts and nuts are used to connect the channels, making installation and modification easier compared to welded connections. 3. Riveted connections: While riveted connections were once popular, they have become less common due to the labor-intensive process involved. Rivets are used to connect channels, offering good strength and durability. However, specialized tools and skills are required for installation. 4. Gusset plate connections: Gusset plate connections employ a steel plate, known as a gusset plate, to connect multiple channels. The gusset plate is usually welded or bolted to the channels, enhancing strength and stability. This type of connection is commonly found in truss structures and applications with significant channel loads. 5. Cleat connections: Cleat connections involve using a steel plate, called a cleat, to connect a channel to another structural member, such as a beam or column. The cleat is typically bolted or welded to both the channel and the other member, ensuring a strong and stable connection. Cleat connections are commonly utilized in steel frame construction. These examples represent a fraction of the steel channel connections used in construction and structural engineering. The choice of connection type depends on factors such as load capacity, adjustability, installation requirements, and design considerations.

- Q: Can steel channels be used in curved structures?

- Yes, steel channels can be used in curved structures. Steel channels can be bent or curved to achieve the desired shape without compromising their structural integrity. This flexibility makes them suitable for various applications in curved structures such as bridges, arches, and curved beams.

- Q: What are the different methods for connecting steel channels?

- There are several methods for connecting steel channels, including welding, bolting, and using mechanical fasteners such as screws or rivets. The choice of method depends on factors such as the structural requirements, load-bearing capacity, and the desired level of flexibility or adjustability in the connection.

- Q: How do steel channels perform in high-humidity environments?

- The performance of steel channels may vary in high-humidity environments depending on specific conditions. Steel is a durable and corrosion-resistant material that is suitable for use in humid environments. However, prolonged exposure to high humidity, especially when certain corrosive substances are present, can cause rust formation and degradation of the steel channels over time. To mitigate the effects of high humidity, protective finishes can be applied to steel channels or corrosion inhibitors can be used. These measures create a barrier between the steel and surrounding moisture, preventing or delaying rust formation. In addition, proper ventilation and moisture control in the environment can help minimize the impact of high humidity on steel channels. Adequate air circulation and the use of dehumidifiers reduce the moisture content in the air, decreasing the chances of rust formation. Regular maintenance and inspections are crucial to detect and address any signs of corrosion early on. Prompt cleaning and reapplication of protective coatings, if necessary, prolong the lifespan and performance of steel channels in high-humidity environments. Overall, while steel channels can withstand high humidity to a certain extent, it is important to take appropriate measures to protect them from excessive moisture and corrosion to ensure their long-term performance and durability.

- Q: Classification, use and material of channel steel

- According to the channel shape and can be divided into 4 kinds: cold bending equilateral channels, cold-formed non equilateral channel steel, cold rolled edge channels, the cold bending edge channels.

- Q: Can steel channels be used in the food processing industry?

- Yes, steel channels can be used in the food processing industry. Steel channels are commonly used for structural support and framing in industrial settings, including food processing facilities. They are durable, strong, and resistant to corrosion, making them suitable for use in environments where hygiene and cleanliness are essential. Additionally, steel channels can be easily cleaned and sanitized, making them a practical choice for the food processing industry.

- Q: Are steel channels suitable for DIY projects?

- Yes, steel channels are suitable for DIY projects. They are versatile and durable, making them ideal for various applications such as building frames, shelving units, and structural supports. Steel channels can be easily cut, drilled, and welded, allowing for customization to fit specific project needs. Additionally, they provide excellent strength and stability, ensuring long-lasting results for DIY enthusiasts.

- Q: How do steel channels contribute to the stability of a structure during high winds?

- Steel channels contribute to the stability of a structure during high winds in several ways. Firstly, steel channels provide structural support and reinforcement to the overall framework of a building. They are typically used as beams or columns, and their strong and rigid nature helps to distribute the forces exerted by high winds throughout the structure. This effectively prevents the building from swaying or collapsing under the intense wind pressure. Additionally, steel channels offer excellent resistance to bending and torsion, making them capable of withstanding the dynamic loads associated with high winds. Their robustness ensures that the structure remains intact and maintains its shape even in the face of strong gusts. Moreover, steel channels can be strategically positioned in critical areas of a building, such as corners or near openings, to further enhance its stability during high winds. By reinforcing these vulnerable points, the channels help to minimize the risk of structural failure or damage. Furthermore, steel channels are often used in conjunction with other structural elements, such as braces or cross beams, to create a more rigid and stable framework. This combination of different structural components effectively increases the overall strength and resilience of the building, providing further protection against the impact of high winds. In summary, steel channels play a crucial role in ensuring the stability of a structure during high winds. Their strength, rigidity, and ability to distribute and withstand forces contribute to the overall structural integrity, preventing the building from being compromised by the strong winds and keeping its occupants safe.

Send your message to us

U Channel Steel/Steel Channel Iron/Galvanized Steel Channel Dimensions

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 40000 PCS/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords