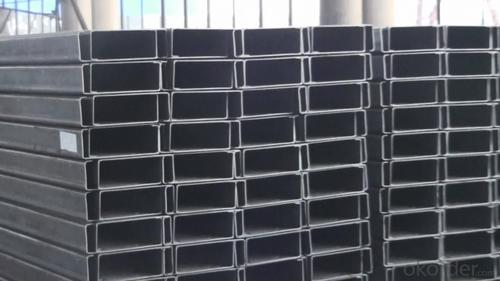

Cold Rolled C Channel

- Loading Port:

- Tianjin Port,China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10Tons m.t.

- Supply Capability:

- 1000 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Cold Rolled C Channel:

1.Our Cold Rolled C Channel has lots of advantages, just as followings:

a) At reasonable price and good quality.

b) To be convenient in construction and to save much time and labor.

c) The length of Cold Rolled C Channel can be manufactured according to customer’s requirements.

d) The Cold Rolled C Channel has strong mechanical strength.

e). The Cold Rolled C Channel possesses various kind of fittings, through which it is suitbal for many combinations.

f) Our Cold Rolled C Channel is attractive in appearance as well as beautiful in design

g) Free from slotted punching

2. The detailed sections of our Cold Rolled C Channel can be found in table-1

Size | Weight(kg/m) | Size | Weight(kg/m) |

80×40×20×2.5 | 3.925 | 180×60×20×3 | 8.007 |

80×40×20×3 | 4.71 | 180×70×20×2.5 | 7.065 |

100×50×20×2.5 | 4.71 | 180×70×20×3 | 8.478 |

100×50×20×3 | 5.652 | 200×50×20×2.5 | 6.673 |

120×50×20×2.5 | 5.103 | 200×50×20×3 | 8.007 |

120×50×20×3 | 6.123 | 200×60×20×2.5 | 7.065 |

120×60×20×2.5 | 5.495 | 200×60×20×3 | 8.478 |

Table-1

Note: we are definitely good at manufacturing and supplying Cold Rolled C Channel as per S235JR. Also, we are willing and able to provide our customers Cold Rolled C Channel in other sizes, which depends on customers’ concret requirements for the quantity.

3. The chemical composition of Cold Rolled C Channel as per S235JR is shown in the table-2

Alloy No | Element(%) | ||||

C | Mn | S | P | Si | |

S235JR | 0.12—0.20 | 0.3—0.7 | ≤0.030 | ≤0.030 | ≤0.20 |

Table-2

4. The mechanical property of Cold Rolled C Channel as per S235JR is shown in the table-3-1 and table-3-2

Alloy No | Yielding strength point( Mpa) | |||

Thickness (mm) | ||||

≤16 | >16--40 | >40--60 | >60--100 | |

≥ | ||||

S235JR | 235 | 225 | 215 | 195 |

Table-3-1

Alloy No | Tensile strength (Mpa) | Elongation after fracture(%) | |||

Thickness (mm) | |||||

| ≤16 | >16--40 | >40--60 | >60--100 | |

≥ | |||||

S235JR | 340--510 | 24 | 23 | 22 | 27 |

Table-3-2

Applications of Cold Rolled C Channel:

The Cold Rolled C Channel can be applied to construction of warehouses, workshops, sport stadiums and car parks etc.The hot rolled channel steel belongs to carbon structural steel which is applied to in the field of construction and machinery.In details, the hot rolled channel steel is usually used for arch-itechtural structure, and they could be welded in order to support or hang a vari-ety of facilities. They are also usually used in combination with I beam. Generally,the hot rolled channel steel we supply must possess perfect welding property, riveting property and mechanical property and so on.

Package & Delivery of Cold Rolled C Channel:

1.The channel steel will be packed in bundle with steel wire at each end of every bundle and color marking in order to help the customer to recognize his goods more easily at sight.

2. And the channel steel could be loaded into 20ft or 40ft container, or by bulk cargo.If the weight of each bundle reaches more than 3.5 mt, the loading by break bulk cargo should be choosed.When the weight of each bundle reaches less than 3mt, the loading by container should be choosed.

3.As for the transportaion from mill to loading port, the truck will be usually used. And the maximum quantity for each truck is 40mt.

4.All in all, we could do in accordance with customer's request.

Production Flow of Cold Rolled C Channel:

1.The steel billet shall be heated in the high temperature furnace.

2. The heated steel billet shall be rolled five to nine times with the aim of shaping the general figure of steel u channel.

3. The rolled steel u channel should be put onto the cooling bed to make the temperature low.

4. The steel u channel should be straighted on the straightener.

5. The straighted steel u channel will be cut into meters by saw, as per customer's requirements.

6. At the last part of production, the channel steel must be tested in order to confirm that the finished products are completely free from crack, pore, slag, scab or fold on the surface.

- Q: What are the recommended safety precautions when working with steel channels?

- When working with steel channels, it is important to follow recommended safety precautions to ensure a safe working environment. These precautions include: 1. Personal protective equipment (PPE): Always wear appropriate PPE such as safety glasses, steel-toed boots, gloves, and a hard hat. This will protect you from potential hazards like falling objects, sharp edges, and sparks. 2. Training: Receive proper training on how to handle steel channels, including how to lift and carry them safely, as they can be heavy and awkward to maneuver. Understanding the proper techniques will help prevent strains, sprains, or other injuries. 3. Inspection: Inspect steel channels before usage to identify any defects or damage. Defective channels can compromise safety, so it is crucial to ensure they are in good condition before installation or use. 4. Secure storage: Store steel channels in a designated area where they are secured properly to prevent them from falling or causing accidents. Proper storage also prevents damage to the channels and reduces the risk of potential injuries. 5. Handling and lifting: When lifting steel channels, always use mechanical lifting equipment or follow proper manual handling techniques. Avoid bending or twisting your body during lifting to avoid strains or back injuries. 6. Fire prevention: Steel channels can create sparks during fabrication or welding processes, so it is important to have fire prevention measures in place. Keep the work area clear of flammable materials, have fire extinguishers readily available, and follow established fire safety protocols. 7. Proper ventilation: Ensure that the work area is well-ventilated to minimize the risk of exposure to fumes or gases that may be released during welding or cutting processes. 8. Communication: Maintain effective communication with other workers in the area to prevent accidents caused by lack of coordination or awareness. Use hand signals, radios, or other appropriate means of communication to ensure everyone is aware of each other's actions. 9. Emergency preparedness: Be familiar with emergency procedures and have a first aid kit readily available. In the event of an accident or injury, knowing how to respond quickly and appropriately can help minimize the severity of the situation. By following these recommended safety precautions, you can significantly reduce the risk of accidents or injuries when working with steel channels. Prioritizing safety ensures a productive and secure work environment for everyone involved.

- Q: Can steel channels be used for railway track support?

- Yes, steel channels can be used for railway track support. They are commonly used as a structural component in railway track systems due to their strength, durability, and ability to provide stable support for the tracks.

- Q: Where does channel steel use more? Where does angle iron use more?

- The stainless steel angle can be made up of different stress components according to the different structure, and it can also be used as the connecting piece between the components. Widely used in a variety of architectural and engineering structures, such as beams, bridge [/url], transmission tower, lifting transport machinery, ships, industrial furnace, reaction tower, container rack and warehouse shelves.Stainless steel angle steel is constructed with carbon structural steel. It is a simple section steel. It is mainly used in the frame of metal component and workshop. In use, better weldability, plastic deformation and mechanical strength are required. The raw material for producing stainless steel angle steel is low carbon square billet, the finished product is made of stainless steel and the angle iron is delivered by hot rolling forming, normalizing or hot rolling.

- Q: What are the connection methods for steel channels in construction?

- There are several connection methods used for steel channels in construction, depending on the specific application and structural requirements. One common method of connecting steel channels is by welding. This involves melting the edges of the channels together and allowing them to cool, creating a strong bond. Welding is often used when the channels need to withstand significant loads and forces. It provides a durable and permanent connection that is resistant to fatigue and corrosion. Another connection method is bolting. In this case, steel channels are joined together using bolts and nuts. Bolting is often preferred when the channels need to be easily disassembled or adjusted. It allows for flexibility in construction and can be quicker than welding. However, it may not be as strong as welded connections and may require regular maintenance to ensure the bolts remain tight. Riveting is another traditional method of connecting steel channels. It involves using metal rivets to hold the channels together. Riveting was commonly used in the past, but it has largely been replaced by welding and bolting due to advancements in technology and the ease of use provided by these methods. However, in certain situations where aesthetics or historical accuracy is important, riveting may still be used. Adhesive bonding is a modern method of connecting steel channels. It involves using high-strength adhesives to bond the channels together. Adhesive bonding is particularly useful when joining dissimilar materials or when a seamless appearance is desired. It can provide a strong and durable connection, but it may not be suitable for all applications and may require special surface preparation and curing time. Ultimately, the choice of connection method for steel channels in construction depends on several factors, including the specific structural requirements, budget constraints, time constraints, and aesthetic considerations. It is important to consider the advantages and disadvantages of each method and select the most appropriate one for the given project.

- Q: How do steel channels contribute to building durability?

- Steel channels contribute to building durability in several ways. Firstly, steel channels provide structural support to the building. They are used to create the framework and framework support for floors, walls, and ceilings. This ensures that the building can withstand heavy loads and remain stable over time. Steel channels have high strength and rigidity, making them resistant to bending, warping, and twisting, which ultimately enhances the overall durability of the structure. Secondly, steel channels are highly resistant to corrosion. They are commonly made from galvanized or stainless steel, both of which have excellent resistance to rust and corrosion. This is particularly important in buildings that are exposed to moisture, such as coastal areas or places with high humidity. By using steel channels, the risk of structural damage caused by rust or corrosion is significantly reduced, leading to increased durability of the building. Furthermore, steel channels offer fire resistance. Steel is inherently non-combustible, meaning it does not contribute to the spread of fire. In the event of a fire, steel channels can help contain the flames and prevent them from spreading to other parts of the building. This fire-resistant property significantly improves the safety and durability of the structure. Lastly, steel channels are highly durable and require minimal maintenance. Unlike other building materials that may deteriorate over time, steel channels have a long lifespan and retain their strength and integrity for many years. They are not susceptible to rot, decay, or insect damage, which can be common issues with wood or other organic materials. This durability and low maintenance requirement make steel channels a cost-effective choice in the long run. In conclusion, steel channels contribute to building durability by providing structural support, corrosion resistance, fire resistance, and low maintenance requirements. Their strength, stability, and longevity make them an ideal choice for creating durable and long-lasting buildings.

- Q: What are the load-bearing properties of steel channels?

- Steel channels have excellent load-bearing properties due to their shape and material composition. The "C" or "U" shape of steel channels provides structural support and stability. The flanges, or horizontal sections, of the channel resist bending moments, while the web, or vertical section, contributes to the channel's overall strength. The load-bearing capacity of steel channels depends on various factors, including their dimensions, thickness, and the grade of steel used. Higher-grade steels typically have greater tensile and yield strengths, enabling them to withstand heavier loads. Steel channels also offer high resistance to compression, making them suitable for applications that require support against vertical forces. Additionally, steel channels can be reinforced or braced to enhance their load-bearing capabilities. This can involve adding additional supports, such as beams or columns, or employing engineering techniques like stiffening plates or welding. Steel channels find numerous applications in construction, infrastructure, and industrial projects, where they are used to support beams, columns, and other structural elements. They are commonly used in the construction of buildings, bridges, factories, and even in vehicle frames. Their load-bearing properties make them a reliable choice for handling heavy loads and ensuring structural integrity.

- Q: Hello, I have a question to ask you, do a steel hoop, the outer diameter of 1688MM, with 8# steel roll, want to ask next to the long material, 8# channel 43, formula I for (1688-43) *3.14159=5168mm, this material, placed above the rolling machine to roll how, outside diameter it is more than 1688 Oh, I would like to ask, feeding formula should start rolling steel...Is it possible to stretch the roll with a profile bending machine? Can you recommend 1-2 units? It's best to have the approximate price. I'd like to consider whether I can buy one. Thank you

- Count the amount, and in turn count how much it should be minus 1688, and then do it. Or leave a little margin, roll it repaired.

- Q: Are steel channels suitable for agricultural storage buildings?

- Yes, steel channels are suitable for agricultural storage buildings. Steel channels offer strength, durability, and versatility, making them ideal for supporting heavy loads and withstanding the harsh conditions often found in agricultural environments. They can effectively support structures such as roofs, walls, and floors, ensuring the safety and longevity of the storage building. Additionally, steel channels can be easily customized and assembled, allowing for flexible design options to meet specific storage needs.

- Q: How are steel channels connected to other structural elements?

- There are multiple ways to connect steel channels to other structural elements. These methods include welding, bolting, and using mechanical connectors. Welding is a popular technique for joining steel channels with other structural elements. This involves melting the base metal of both the channel and the adjacent structure, fusing them together to form a robust and permanent connection. Welding offers exceptional strength and rigidity, making it ideal for heavy-duty applications. Another frequently employed method is bolting. This method entails drilling holes through the flanges of the channel and the adjacent structure. Bolts are then inserted through these holes to secure the connection. Bolting allows for a flexible and reversible connection, enabling easy disassembly or modification if necessary. Mechanical connectors, such as beam clamps or channel connectors, can also be utilized to connect steel channels with other structural elements. These connectors are designed for easy attachment to the channel and subsequent securing to the adjacent structure using bolts or other fasteners. Mechanical connectors offer a convenient and efficient way to connect steel channels without the need for welding or complex fabrication. The choice of connection method depends on several factors, including structural design, load requirements, accessibility, and project specifications. Engineers and designers carefully consider these factors to determine the most suitable method for connecting steel channels to other structural elements. This ensures a secure and durable connection that meets the project's specific needs.

- Q: Can steel channels be used in mezzanine construction?

- Certainly! Mezzanine construction can certainly benefit from the usage of steel channels. These channels are widely employed in the construction of buildings due to their exceptional strength and longevity. Mezzanines, which are intermediate floors inserted between a building's primary floors, enhance the available space and functionality. To ensure stability and support for the structure, steel channels can be utilized as either beams or columns in mezzanine construction. Their fabrication and installation are hassle-free, rendering them an optimal choice for mezzanine construction projects. Furthermore, steel channels can be tailor-made to meet specific design requirements and can be combined with other steel components like plates and angles, resulting in a sturdy and dependable mezzanine structure.

1. Manufacturer Overview

| Location | Tianjin, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 15 Million |

| Main Markets | Southeast Asia; Africa |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 15%-20% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 6,500 square meters |

| No. of Production Lines | 1 |

| Contract Manufacturing | OEM service offered |

| Product Price Range | average |

Send your message to us

Cold Rolled C Channel

- Loading Port:

- Tianjin Port,China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10Tons m.t.

- Supply Capability:

- 1000 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords