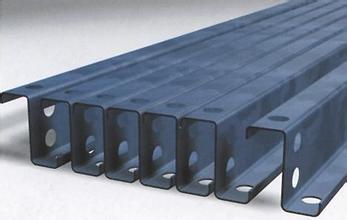

Quality Steel Z-Channel (Thickness: 2.0mm)

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 PCS

- Supply Capability:

- 2000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering high Quality Steel Z-Channels (Thickness: 2.0mm) at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Quality Steel Z-Channels (Thickness: 2.0mm) are ideal for structural applications and general fabricating.

Product Advantages:

OKorder's Steel Channels are durable, strong, and resists corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (10-25 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Grade: Q195-Q345/SPCC

Manufacture: Cold forming

Shape: Z-channel

Dimensions:

Base: 35mm – 400mm

Width: 15mm – 25mm

Height: 80mm – 350mm

Thickness: 0.3mm – 6mm

Place of Origin: Tianjin, China

Certifications: ISO 9001:2000, TUV

Production: 20,000 tons/month

Processing Available: Threading, coupling, plastic cap protection

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: What are the methods and the price of building the floor?

- Channel or I-beam construction. Under normal circumstances, the use of channel steel on the line, but with the bending strength of I-beam will be higher, of course, the cost will be higher, but also occupy more space I-beam height. The advantage of channel steel construction is that it is quick to use. It does not need to wait. The disadvantage is that the channel made attic, when people walk in the above, there will be a certain shaking sound, the smaller channel specifications, the greater the shaking. The adoption of channel steel is a recommended practice.

- Q: What is the weight of a standard steel channel?

- The weight of a standard steel channel can vary depending on its dimensions and thickness. However, as a general guideline, a standard steel channel typically weighs around 10 to 20 pounds per foot.

- Q: How do steel channels contribute to the overall sustainability of a structure?

- Steel channels contribute to the overall sustainability of a structure in several ways. First and foremost, steel is a highly durable and long-lasting material. It is resistant to corrosion, weathering, and degradation, which means that structures built with steel channels have a longer lifespan compared to structures made with other materials. This durability reduces the need for frequent repairs or replacements, ultimately reducing the environmental impact associated with construction and demolition waste. Additionally, steel channels are lightweight yet strong, allowing for efficient use of materials. This means that less steel is required to achieve the same structural strength, leading to reduced resource consumption and energy usage during the manufacturing process. Moreover, steel is a recyclable material, and steel channels can be easily repurposed or recycled at the end of their life cycle. Recycling steel reduces the demand for new raw materials and saves energy that would be required in the production of new steel. Furthermore, steel channels offer design flexibility and versatility, enabling architects and engineers to create innovative and sustainable structures. Steel channels can be easily shaped, welded, and assembled, facilitating the construction process and allowing for a wide range of architectural designs. This flexibility also allows for future modifications or expansions without requiring extensive demolition or reconstruction. Lastly, steel channels have excellent fire resistance properties. Steel is non-combustible and does not contribute to the spread or intensity of fires, which enhances the safety of the structure and reduces the risk to occupants and neighboring buildings. In summary, steel channels contribute to the overall sustainability of a structure through their durability, efficient use of materials, recyclability, design flexibility, and fire resistance. By choosing steel channels, we can create structures that are not only environmentally friendly but also safe, long-lasting, and cost-effective in the long run.

- Q: Small Huxing, suitable for what modeling ceiling, channel across 4.8 meters, 60cm file, middle angle steel, 60cm first gear, what kind of modeling ceiling?

- There are many methods, after is to see the steel structure to do the story, there is one of the most direct, general is flat, sticking a layer of gypsum board in the bottom of the steel structure, steel structure and hollow middle position, placing lamp to lighting as the auxiliary light source, this is also very beautiful;

- Q: What do you mean by "A" in the channel type?

- A thin waist is the most.The width of their legs is equal to the waist thickness difference, that is, the real leg (not including waist thickness) is the same length, and the average leg thickness is the same.

- Q: What are the different grades of steel used for channels?

- Channels are commonly made from various grades of steel. The choice of steel grade depends on the desired properties and intended application. A36 steel is one grade that is frequently utilized. It is a low carbon steel known for its versatility and excellent weldability. Due to its strength and durability, it is often employed in structural applications, such as channels. Another grade that is commonly used is A572 steel. This is a high-strength, low-alloy steel that offers improved strength and corrosion resistance compared to A36 steel. It is suitable for demanding applications, including heavy-duty construction projects. Additional grades of steel that may be employed for channels include A588 steel, which is known for its corrosion resistance in weathering conditions, and A500 steel, which is a structural steel often used in construction and infrastructure projects. To determine the most suitable grade of steel for a specific channel application, it is important to consult with a structural engineer or steel supplier. Factors such as load-bearing capacity, corrosion resistance, and environmental conditions should be taken into consideration.

- Q: How are steel channels connected to other structural members?

- Steel channels can be connected to other structural members through various methods such as welding, bolting, or using mechanical connectors. This ensures a secure and stable connection between the steel channels and the other structural components, enabling them to function together as a unified system.

- Q: Can steel channels be used in the pharmaceutical industry?

- Indeed, the pharmaceutical industry can utilize steel channels. Renowned for their versatility, steel channels are widely employed across diverse sectors, including pharmaceuticals. Their primary function lies in offering support to mechanical equipment like conveyors and processing machines within pharmaceutical manufacturing facilities. By providing stability, strength, and durability, steel channels prove ideal for applications demanding substantial loads and stringent hygiene standards. Furthermore, steel channels ensure effortless cleaning and sanitization, a pivotal requirement in the pharmaceutical industry to uphold sterility and thwart contamination.

- Q: How do steel channels perform in extreme temperature variations?

- Steel channels generally perform well in extreme temperature variations. Steel has a high melting point and excellent thermal conductivity, allowing it to withstand both high and low temperatures without significant deformation or structural damage. However, some precautions may be necessary in extremely cold conditions to prevent brittleness. Overall, steel channels are a reliable choice for applications where temperature variations are a concern.

- Q: What does channel C10 mean? What is the full name of C?

- Decent channel steel, with two thicker legs, does not curl (it rolls too tightly). Used for stressed structures.

Send your message to us

Quality Steel Z-Channel (Thickness: 2.0mm)

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 PCS

- Supply Capability:

- 2000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords