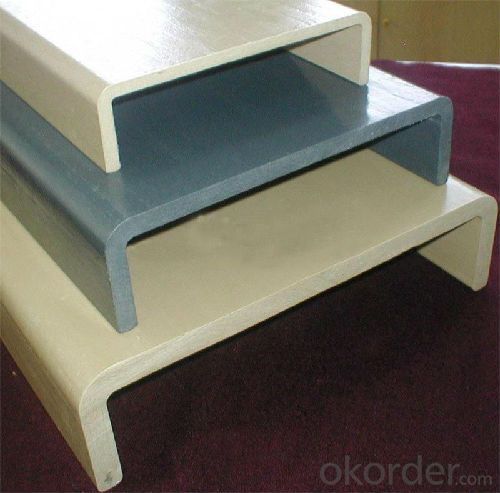

U CHANNEL JIS G3192 5mm-300mm Hot Rolled High Quality or GB Q235

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering U CHANNEL JIS G3192 5mm-300mm Hot Rolled High Quality or GB Q235at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

1.The JIS U Channel Steel can be devided into two kinds, namely common channel steel and light channel steel. The sizes of hot rolled common channel steel range from 5# to 40#. Meanwhile, the channel steel can be divided into cold forming sectional equal channel steel, cold forming sectional unequal channel steel, cold forming inner edge channel steel and outer edge channel steel.

2.The JIS u channel steel is usually used for arch-itechtural structure, and they could be welded in order to support or hang a vari-ety of facilities. They are also usually used in combination with I beam. The channel steel with sizes under 14# is usually applied to construction engineering, as purline, while the channel steel with sizes above 16# is more likely to be used in building vehicle chassis structure and mechanical structure. Furthermore, the channel steel in sizes above 30# are target at building bridge structure, as tension bar.

3.In a word, the channel steel must possess perfect welding property, riveting property and mechanical property and so on.

Product Advantages:

OKorder's U CHANNEL JIS G3192 5mm-300mm Hot Rolled High Quality or GB Q235 re durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Original Place | Tangshan, China | Brand Name | UINDA |

Standard | JIS G3192 : 1990 | ||

Material Grade | SS490 | ||

Sizes | 50mm to 200mm | ||

Sales Volume/Year | 3000MT | ||

Destination Area | Middle East, Africa, Southeast Asia | ||

2. The sections in details are as followings in the table-1

JIS U CHANNEL | Standard | Sectional | Dimension |

| Mass: |

| (mm) | (mm) | (mm) | (mm) |

|

50x25 | 50 | 25 | 3.0 | 6.00 | 2.37 |

75X40 | 75 | 40 | 3.8 | 7.00 | 5.30 |

75X40 | 75 | 40 | 4.0 | 7.00 | 5.60 |

75X40 | 75 | 40 | 4.5 | 7.00 | 5.85 |

75X40 | 75 | 40 | 5.0 | 7.00 | 6.92 |

|

|

|

|

|

|

100X50 | 100 | 50 | 3.8 | 6.00 | 7.30 |

100X50 | 100 | 50 | 4.2 | 6.00 | 8.03 |

100X50 | 100 | 50 | 4.5 | 7.50 | 8.97 |

100X50 | 100 | 50 | 5.0 | 7.50 | 9.36 |

|

|

|

|

|

|

125X65 | 125 | 65 | 5.2 | 6.80 | 11.66 |

125X65 | 125 | 65 | 5.3 | 6.80 | 12.17 |

125X65 | 125 | 65 | 5.5 | 8.00 | 12.91 |

125X65 | 125 | 65 | 6.0 | 8.00 | 13.40 |

|

|

|

|

|

|

150x75 | 150 | 75 | 5.5 | 7.30 | 14.66 |

150x75 | 150 | 75 | 5.7 | 10.00 | 16.71 |

150x75 | 150 | 75 | 6.0 | 10.00 | 17.90 |

150x75 | 150 | 75 | 6.5 | 10.00 | 18.60 |

150x75 | 150 | 75 | 6.5 | 10.00 | 24.00 |

|

|

|

|

|

|

200X80 | 200 | 80 | 7.5 | 11.00 | 24.60 |

3. The mechanical property of JIS U Channel Steel in the table-2:

Grade | Yield Strength,N/mm² | Extension Strength N/mm² | |||

Thickness of Steel,mm | |||||

≦16 | >16-≦40 | >40-≦100 | >100 | ||

SS490 | ≧285 | ≧275 | ≧255 | ≧245 | 490-610 |

4. The chemical composition of JIS U Channel Steel as per SS490 in the table-3

Grade | Element(%) | |||

C | Mn | P | S | |

SS490 | - | - | ≦0.050 | ≦0.050 |

FAQ:

Q1 How do we guarantee the quality of our products?

A1 We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q2 How soon can we receive the product after purchase?

A2 Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q3 What makes stainless steel stainless?

A3 Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

- Q: Can steel channels be customized to specific lengths?

- Indeed, it is possible to customize steel channels to meet specific length requirements. Although steel channels are typically found in standard sizes, they can be altered or trimmed to match the desired length. This customization process entails cutting the steel channel to the desired length and may also involve implementing welding or other techniques to uphold its structural integrity. The ability to customize steel channels offers enhanced flexibility in a variety of construction and engineering applications.

- Q: What are the different methods of protecting steel channels from rust?

- There are several methods available to protect steel channels from rust. 1. Galvanization: This is a widely used method where the steel channels are coated with a layer of zinc. The zinc acts as a sacrificial layer, protecting the steel from corrosion. Galvanized steel channels have high resistance to rust even in harsh environments. 2. Powder coating: This method involves applying a dry powder onto the surface of the steel channels and then heating it to create a protective layer. Powder coating provides excellent corrosion resistance and also offers a variety of color options. 3. Paint or primer: Applying a layer of paint or primer to the steel channels can help protect them from rust. The paint creates a barrier between the steel and the surrounding environment, preventing moisture and oxygen from reaching the metal surface. 4. Epoxy coating: Epoxy coatings are often used in industrial settings to protect steel channels from corrosion. These coatings offer excellent adhesion, chemical resistance, and durability, providing long-term protection against rust. 5. Stainless steel: Using stainless steel channels is an effective way to prevent rust. Stainless steel contains a high percentage of chromium, which forms a passive protective layer on the surface, making it highly resistant to corrosion. 6. VCI (Volatile Corrosion Inhibitors): VCI films or papers can be used to wrap or line steel channels. These materials release vapor-phase corrosion inhibitors that protect the metal surface from rust. 7. Cathodic protection: This method involves connecting the steel channels to a sacrificial anode, such as zinc or magnesium. The anode corrodes instead of the steel, protecting it from rust. It is important to select the appropriate method based on the specific environment, budget, and desired level of protection. Regular maintenance and inspection of the steel channels are also crucial to identify any signs of corrosion and take necessary measures to prevent further damage.

- Q: How do steel channels compare to other structural steel shapes?

- Steel channels are a versatile structural steel shape that offer several advantages compared to other shapes. They are lightweight yet strong, making them suitable for a wide range of applications. Steel channels provide excellent structural support due to their C-shaped design, which allows for greater load-bearing capacity. Additionally, their flanges can be easily attached to other components, enhancing their versatility in construction projects. Overall, steel channels offer a cost-effective and efficient solution for various structural needs.

- Q: What are the different weight classifications for steel channels?

- Steel channels are classified based on their weight per linear foot. The weight classifications for steel channels include lightweight, medium weight, and heavy weight. Lightweight steel channels typically have a weight per linear foot ranging from 1.0 to 6.0 pounds. These channels are commonly used in applications where strength is not the primary concern and where the load requirements are relatively lower, such as in decorative or non-structural applications. Medium weight steel channels have a weight per linear foot ranging from 6.1 to 16.0 pounds. These channels are often used in structural applications where moderate strength and load-bearing capacity are required, such as in building frames, supports, and bracing. Heavy weight steel channels have a weight per linear foot ranging from 16.1 to 40.0 pounds. These channels are designed to provide maximum strength and load-bearing capacity and are commonly used in heavy-duty structural applications such as industrial buildings, bridges, and infrastructure projects. It is important to note that the weight classifications for steel channels may vary depending on the specific standards and specifications set by different countries and organizations.

- Q: What are the precautions for handling and storing steel channels?

- When handling and storing steel channels, it is important to take certain precautions to ensure safety and prevent damage. Some of the precautions include using appropriate lifting equipment and techniques to avoid injuries, wearing personal protective equipment such as gloves and safety boots, and inspecting the channels for any defects or damage before handling them. Additionally, steel channels should be stored in a dry and well-ventilated area to prevent corrosion and damage. It is also important to stack the channels properly, ensuring that they are supported evenly to avoid any bending or warping.

- Q: How to install solid wood fence at the gate of the channel gate? Specifically, how to fix the solid wood column to the channel steel? (a gypsum board spread over a channel

- It is not clear how the column should have been fixed. The channel steel can be drilled and fixed by screws, and a steel plate can be welded on the channel so that the column can be installed

- Q: Can steel channels be used for roof structures?

- Yes, steel channels can be used for roof structures. Steel channels are commonly used in construction for their strength and durability. They provide structural support and can be used as purlins or rafters in roof systems. Steel channels are able to withstand heavy loads and provide stability to the overall structure. They can also be easily fabricated and installed, making them a popular choice for roof construction. Additionally, steel channels are resistant to fire, corrosion, and pests, making them a reliable and long-lasting option for roof structures.

- Q: How do steel channels compare to other structural materials like wood or concrete?

- Steel channels have several advantages over other structural materials like wood or concrete. Firstly, steel channels have a higher strength-to-weight ratio, meaning they can support greater loads with less material. This makes them more efficient and cost-effective in construction projects. Additionally, steel channels are more durable and resistant to rot, pests, and fire compared to wood. They also offer better dimensional stability, allowing for precise construction and reducing the risk of warping or shrinking. Compared to concrete, steel channels offer greater flexibility in design and can be easily modified or reconfigured if needed. Moreover, steel channels have a longer lifespan and require less maintenance than wood or concrete. Overall, steel channels are a superior structural material due to their strength, durability, versatility, and longevity.

- Q: #10 how to anchor the channel steel on the foundation, the anchor bars generally choose how much?

- On the basis of the embedded 20 thick steel plate, with high-strength bolts or chemical bolts fixed, and then use the stiffener to clamp the middle of the channel, and use high-strength bolts to connect.

- Q: How do steel channels perform in high-seismic areas?

- Steel channels perform well in high-seismic areas due to their inherent strength and ductility. In seismic zones, the ground experiences intense shaking and lateral forces, which can cause buildings to undergo significant structural deformation. Steel channels, with their ability to flex and absorb energy, are better equipped to withstand these forces compared to other building materials. The shape of steel channels, with their flanges and web, provides enhanced strength and rigidity. This allows them to resist bending and twisting forces, ensuring the overall stability of structures in high-seismic areas. Furthermore, steel channels can be designed to have tapered flanges, which improves their load-carrying capacity and reduces the risk of buckling during seismic events. Another advantage of steel channels in high-seismic areas is their ability to dissipate energy. During an earthquake, the channel's flexible nature allows it to absorb and distribute the seismic forces, minimizing the impact on the structure. This energy absorption capability reduces the chances of structural damage and enhances the safety of occupants inside the building. Moreover, steel channels offer versatility in design and construction. They can be easily integrated into various structural systems, such as moment frames and braced frames, which are commonly used in earthquake-resistant buildings. This flexibility allows for efficient and cost-effective construction in high-seismic areas. Overall, steel channels provide reliable performance in high-seismic areas by offering strength, flexibility, and energy dissipation capabilities. Their ability to withstand intense shaking and lateral forces makes them a preferred choice for structural applications in seismic zones, ensuring the safety and resilience of buildings in such areas.

Send your message to us

U CHANNEL JIS G3192 5mm-300mm Hot Rolled High Quality or GB Q235

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords