U Channel steel

- Loading Port:

- Xingang Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 100000MTS/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of U Channel Steel:

1.Our company enjoys high reputation on manufacturing and supplying U channel steel. Among those steel products, the U channel steel as per japanese, chinese and european can be regarded as our primary products.

Under those standard, the material grade includes: GB Q235B,GB Q345B/JIS G3192, SS400/EN 10025,S235JR and so on.

Here,the U channel steel as per japanese standard is posted just as reference.

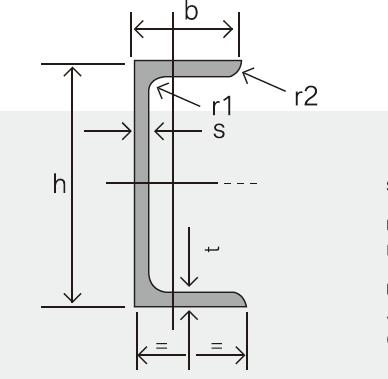

2. Dimension Figure:

Note:1.The height ranges from 50mm to 300mm

2.The breadth ranges from 25mm to 89mm

3.Theoretically speaking, the flange of U channel steel should bear stress, it’s to say that the U channel should be upright rather than lying under construction. Therefore, we strictly control the tolerance of the flange thickness.

3.The sections of U Channel Steel as per JIS Standard are shown in the below table:

JIS U CHANNEL | Standard h | Sectional b | Dimension s | t | Mass: Kg/m |

| (mm) | (mm) | (mm) | (mm) |

|

50x25 | 50 | 25 | 3.0 | 6.00 | 2.37 |

75X40 | 75 | 40 | 3.8 | 7.00 | 5.30 |

75X40 | 75 | 40 | 4.0 | 7.00 | 5.60 |

75X40 | 75 | 40 | 4.5 | 7.00 | 5.85 |

75X40 | 75 | 40 | 5.0 | 7.00 | 6.92 |

|

|

|

|

|

|

100X50 | 100 | 50 | 3.8 | 6.00 | 7.30 |

100X50 | 100 | 50 | 4.2 | 6.00 | 8.03 |

100X50 | 100 | 50 | 4.5 | 7.50 | 8.97 |

100X50 | 100 | 50 | 5.0 | 7.50 | 9.36 |

|

|

|

|

|

|

125X65 | 125 | 65 | 5.2 | 6.80 | 11.66 |

125X65 | 125 | 65 | 5.3 | 6.80 | 12.17 |

125X65 | 125 | 65 | 5.5 | 8.00 | 12.91 |

125X65 | 125 | 65 | 6.0 | 8.00 | 13.40 |

|

|

|

|

|

|

150x75 | 150 | 75 | 5.5 | 7.30 | 14.66 |

150x75 | 150 | 75 | 5.7 | 10.00 | 16.71 |

150x75 | 150 | 75 | 6.0 | 10.00 | 17.90 |

150x75 | 150 | 75 | 6.5 | 10.00 | 18.60 |

150x75 | 150 | 75 | 6.5 | 10.00 | 24.00 |

|

|

|

|

|

|

200X80 | 200 | 80 | 7.5 | 11.00 | 24.60 |

5.Mechanical Property of U Channel Steel as per JIS Standard:

Grade | Yield Strength,N/mm² | Extension Strength N/mm² | |||

Thickness of Steel,mm | |||||

≦16 | >16-≦40 | >40-≦100 | >100 | ||

SS330 | ≧205 | ≧195 | ≧175 | ≧165 | 330-430 |

SS400 | ≧245 | ≧235 | ≧215 | ≧205 | 400-510 |

SS490 | ≧285 | ≧275 | ≧255 | ≧245 | 490-610 |

SS540 | ≧400 | ≧390 | - | - | ≧540 |

6. Chemical Composition of U Channel Steel as per JIS Standard:

Grade | Element(%) | |||

C | Mn | P | S | |

SS330 | -- | -- | ≦0.050 | ≦0.050 |

SS400 | ||||

SS490 | ||||

SS540 | ≦0.30 | ≦1.60 | ≦0.040 | ≦0.040 |

Note: we are also competent to supply structure steel u channel as per other sections, which depends on the customer's requirements for the quantity.

Applications of U Channel Steel:

U channel steel could be regarded as carbon steel or plain steel. Typically, it is stiff and strong. Carbon steels do rust easily, but they can be easily painted or primed. They are cheap so they are the normal choice for most fabrications. U channel steel is often used as supporting members, most commonly in the house raising industry to strengthen timber bears under houses. Transmission line towers.

And our products are widely used in Architectural Constructions,Telecom tower,Sub Station Structure,Microwave tower Factory and warehousing shed,Electrification projects, poles and earthing E.O.T. cranes,Material handling equipments,Ship building,Automobile

Package & Delivery of U Channel Steel:

The u channel steel will be packed in bundle with steel wire at each end of every bundle and color marking in order to help the customer to recognize his goods more easily at sight.

And u channel steel could be loaded into 20ft or 40ft container, or by bulk cargo. If the weight of each bundle reaches less than 3.5 mt, the loading by break bulk cargo should be choosed. When the weight of each bundle reaches less than 3mt, the loading by container should be choosed.

As for the transportaion from mill to loading port, the truck will be usually used. And the maximum quantity for each truck is 40mt.

In a word, we do try our best to satisfy all the customer's requirements.

Production Flow of Steel U Channel:

1.The steel billet shall be heated in the high temperature furnace.

2. The heated steel billet shall be rolled five to nine times with the aim of shaping the general figure of steel u channel.

3. The rolled steel u channel should be put onto the cooling bed to make the temperature low.

4. The steel u channel should be straighted on the straightener.

5. The straighted steel u channel will be cut into meters by saw, as per customer's requirements.

- Q: What are the different types of accessories available for steel channels?

- There are several different types of accessories available for steel channels, each serving a specific purpose and enhancing the functionality of the channels. Some of the common accessories include: 1. Brackets: These are used to provide additional support to the steel channels, especially when they are installed vertically or at an angle. Brackets help in maintaining the structural integrity of the channels and prevent them from sagging or bending. 2. End Caps: These are used to cover the ends of the steel channels, providing a clean and finished look. End caps also protect the edges of the channels from corrosion, moisture, and other external elements. 3. Connectors: Connectors are used to join two or more steel channels together. They come in various shapes and sizes, such as straight connectors, angle connectors, and T-connectors, and are generally made of metal to ensure a strong and secure connection. 4. Mounting Hardware: Mounting hardware includes screws, bolts, and nuts that are used to secure the steel channels to different surfaces or structures. These accessories ensure that the channels are securely fastened and can withstand the load or weight they are intended to support. 5. Sliding Trolleys: Sliding trolleys are used in applications where the steel channels need to support movable loads or equipment, such as sliding doors or conveyor systems. These trolleys allow smooth and easy movement along the channels, providing flexibility and convenience. 6. Cable Management Accessories: Steel channels are often used for cable management purposes, and there are various accessories available to facilitate this. These can include cable clamps, cable ties, cable trays, and cable routing fittings. These accessories help in organizing and securing cables within the channels, ensuring a tidy and efficient cable management system. 7. Hangers and Supports: Hangers and supports are used to suspend or hang the steel channels from ceilings, walls, or other structures. They provide stability and ensure that the channels are properly supported, especially in applications where the channels are used to carry heavy loads. 8. Protective Coatings: While not directly accessories, protective coatings are essential for steel channels to enhance their durability and resistance to corrosion. Coatings such as galvanization or powder coating are commonly applied to protect the steel channels from rust, moisture, and other environmental factors. These are just a few examples of the different types of accessories available for steel channels. Depending on the specific application and requirements, there may be additional accessories or variations of the above-mentioned accessories that can be used to maximize the performance and functionality of steel channels.

- Q: Do steel channels have any specific safety considerations?

- Indeed, specific safety considerations must be taken into account when dealing with steel channels. These channels are widely utilized in construction and industrial settings to provide structural support, but mishandling them can result in certain safety hazards. One aspect to consider is the weight and dimensions of steel channels. Due to their heaviness and unwieldiness, proper lifting techniques must be employed to prevent strain or harm to workers. Furthermore, caution should be exercised when working in proximity to or underneath steel channels to prevent potential accidents in the event of a fall or collapse. Another safety concern pertains to the sharp edges and corners of steel channels. These sharp surfaces can cause lacerations or punctures if adequate precautions are not taken. To minimize the risk of injury, workers should don appropriate protective gear, including gloves, safety glasses, and steel-toed boots. Additionally, fire safety should not be overlooked when working with steel channels. As steel is an excellent conductor of heat, steel channels can become hot during a fire incident. To minimize the spread of fire through these channels, suitable fire prevention measures and fire-resistant coatings should be implemented. Lastly, ensuring proper installation and maintenance of steel channels is crucial to uphold their structural integrity and safety. Regular inspections should be conducted to identify any signs of corrosion, damage, or fatigue. Promptly addressing any issues can prevent potential structural failures or accidents. In conclusion, although steel channels are known for their durability and widespread use, it is vital to be mindful of the specific safety considerations associated with them. By adhering to proper safety protocols, workers can mitigate risks and maintain a safe working environment.

- Q: How do steel channels perform in high-traffic areas?

- Due to their durability and strength, steel channels are highly effective in high-traffic areas. These channels, also known as steel C-channels, are commonly used in construction and industrial projects to provide support and stability. Their robustness ensures they can withstand heavy loads, impacts, and constant foot traffic without sustaining damage. In high-traffic areas like walkways, bridges, and commercial spaces, steel channels offer numerous benefits. Firstly, they are capable of handling significant weight without bending or warping, guaranteeing long-lasting performance even under extreme pressure. This makes them ideal for supporting heavy machinery, vehicles, or large groups of people. Additionally, steel channels possess exceptional corrosion resistance, which is crucial in high-traffic areas prone to moisture and other environmental factors. They can endure exposure to rain, snow, and chemicals without deteriorating, making them suitable for outdoor applications. Moreover, steel channels contribute to stability and safety in high-traffic areas. Their rigid structure and precise dimensions enable secure installation, reducing the risk of accidents or structural failures. This is essential in places where public safety is a concern, such as airports, train stations, or sports arenas. Furthermore, steel channels can be easily customized to meet specific project requirements. They can be cut, drilled, or welded to fit unique dimensions or angles, allowing for versatile applications in diverse high-traffic settings. This adaptability makes them highly suitable for projects with complex design needs. To summarize, steel channels are an excellent option for high-traffic areas due to their durability, strength, corrosion resistance, stability, and customization capabilities. They provide reliable support and long-lasting performance, making them a dependable solution for both indoor and outdoor applications in demanding environments.

- Q: Can steel channels be used in signage applications?

- Steel channels are a viable option for signage applications. They serve as a sturdy and stable structural support for signage panels. These channels are frequently utilized in outdoor signage projects, including billboards, highway signs, and store signs. Depending on the sign's design and dimensions, steel channels can be installed either horizontally or vertically. Moreover, they possess durability and resistance to weather elements, ensuring the longevity of outdoor signage. Furthermore, steel channels can be effortlessly tailored and manufactured to meet specific signage demands, encompassing size, shape, and color. In conclusion, steel channels offer versatility and dependability for a wide range of signage applications.

- Q: Can steel channels be used for elevator shafts?

- Yes, steel channels can be used for elevator shafts. Steel channels, which are structural components made of steel in a "C" shape, are commonly used in construction for various purposes, including elevator shafts. Steel channels provide strength, stability, and support to the elevator shaft structure, ensuring its ability to withstand the weight and load of the elevator car, as well as any additional loads such as people or heavy equipment. Additionally, steel channels can be easily fabricated and customized to fit the specific requirements of the elevator shaft, making them a suitable choice for this application.

- Q: What are the maintenance requirements for steel channels?

- The maintenance requirements for steel channels primarily involve regular cleaning and inspection to ensure their structural integrity and prevent corrosion. Cleaning should be done using a mild soap and water solution or a non-abrasive cleaner to remove any dirt, dust, or debris that may accumulate on the surface of the channels. It is important to avoid using harsh chemicals or abrasive cleaners as they can damage the protective coatings on the steel. Regular inspection is crucial to identify any signs of wear, damage, or rust formation. Any visible signs of rust should be addressed immediately by removing the rust using a wire brush and applying a rust-inhibiting primer and paint to protect the steel from further corrosion. In areas with high humidity or exposure to saltwater or chemicals, more frequent inspections and maintenance may be required. Additionally, it is important to keep the steel channels clear of any obstructions or debris that could impede their functionality or compromise their structural integrity. Regular checks should be made to ensure that the channels are properly aligned and securely fastened to their support structure. Proper maintenance practices for steel channels will extend their lifespan and ensure they continue to perform their intended function effectively. It is also recommended to follow any manufacturer-specific maintenance guidelines or consult with a professional for specific requirements based on the application and environment in which the steel channels are installed.

- Q: What is the weight of a steel channel?

- The weight of a steel channel depends on various factors such as its dimensions and thickness. Steel channels are typically measured in terms of their weight per foot or weight per meter. To determine the weight of a steel channel, you would need to know its dimensions, including the height, width, and thickness. By using the appropriate formula or consulting a steel weight chart, you can calculate the weight of a steel channel.

- Q: How do steel channels contribute to the modular construction process?

- Steel channels play a crucial role in the modular construction process by providing structural support and stability. These channels are commonly used as framing elements in modular buildings, helping to create a strong and durable framework. They are also used to connect different modules together, ensuring a secure and seamless construction. Additionally, steel channels offer flexibility in design, allowing for easy customization and adaptation to different project requirements. Overall, steel channels significantly contribute to the efficiency, strength, and versatility of modular construction.

- Q: How to connect channel steel and round steel?

- End face of channel steel and end face of round steel:Can first welding a large circular steel plate and steel bar etc. in the channel to the end faces of the circular plate thickness should be more than 10mm, then the circular plate side angle steel and round steel bar to coincide welding, chamfering, need full welding between the two.

- Q: Are steel channels suitable for agricultural storage buildings?

- Yes, steel channels are suitable for agricultural storage buildings. Steel channels offer strength, durability, and versatility, making them ideal for supporting heavy loads and withstanding the harsh conditions often found in agricultural environments. They can effectively support structures such as roofs, walls, and floors, ensuring the safety and longevity of the storage building. Additionally, steel channels can be easily customized and assembled, allowing for flexible design options to meet specific storage needs.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 1993 |

| Annual Output Value | Above US$100 Million |

| Main Markets | South Asia Middle East; Southeast Aisa; south Korea |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 20,000 square meters |

| No. of Production Lines | 1 |

| Contract Manufacturing | OEM service offered |

| Product Price Range | average |

Send your message to us

U Channel steel

- Loading Port:

- Xingang Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 100000MTS/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords