Cold-Rolled C Bar

- Loading Port:

- Tianjin Port,China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20Tons m.t.

- Supply Capability:

- 1000 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Cold-Rolled C Bar:

1. We are definitely speciallizing in manufacturing and supplying channel steel as per japanese standard, which is characterised with high mechanical strength and competitive prices.

2. The sections in details are as followings in the table-1

Size | Weight(kg/m) | Size | Weight(kg/m) |

80×40×20×2.5 | 3.925 | 180×60×20×3 | 8.007 |

80×40×20×3 | 4.71 | 180×70×20×2.5 | 7.065 |

100×50×20×2.5 | 4.71 | 180×70×20×3 | 8.478 |

100×50×20×3 | 5.652 | 200×50×20×2.5 | 6.673 |

120×50×20×2.5 | 5.103 | 200×50×20×3 | 8.007 |

120×50×20×3 | 6.123 | 200×60×20×2.5 | 7.065 |

120×60×20×2.5 | 5.495 | 200×60×20×3 | 8.478 |

120×60×20×3 | 6.594 | 200×70×20×2.5 | 7.458 |

120×70×20×2.5 | 5.888 | 200×70×20×3 | 8.949 |

120×70×20×3 | 7.065 | 220×60×20×2.5 | 7.4567 |

140×50×20×2.5 | 5.495 | 220×60×20×3 | 8.949 |

140×50×20×3 | 6.594 | 220×70×20×2.5 | 7.85 |

160×50×20×2.5 | 5.888 | 220×70×20×3 | 9.42 |

160×50×20×3 | 7.065 | 250×75×20×2.5 | 8.634 |

160×60×20×2.5 | 6.28 | 250×75×20×3 | 10.362 |

160×60×20×3 | 7.536 | 280×80×20×2.5 | 9.42 |

160×70×20×2.5 | 6.673 | 280×80×20×3 | 11.304 |

160×70×20×3 | 8.007 | 300×80×20×2.5 | 9.813 |

180×50×20×2.5 | 6.28 | 300×80×20×3 | 11.775 |

180×50×20×3 | 7.536 | ||

180×60×20×2.5 | 6.673 |

Table-1

3. The mechanical property of Cold-Rolled C Bar in the table-2:

Grade | Yield Strength,N/mm² | Extension Strength N/mm² | |||

Thickness of Steel,mm | |||||

≦16 | >16-≦40 | >40-≦100 | >100 | ||

SS330 | ≧205 | ≧195 | ≧175 | ≧165 | 330-430 |

SS400 | ≧245 | ≧235 | ≧215 | ≧205 | 400-510 |

SS490 | ≧285 | ≧275 | ≧255 | ≧245 | 490-610 |

SS540 | ≧400 | ≧390 | - | - | ≧540 |

Table-2

4. The chemical composition of Cold-Rolled C Bar in the table-3

Grade | Element(%) | |||

C | Mn | P | S | |

SS330 | -- | -- | ≦0.050 | ≦0.050 |

SS400 | ||||

SS490 | ||||

SS540 | ≦0.30 | ≦1.60 | ≦0.040 | ≦0.040 |

Table-3

Usage of Cold-Rolled C Bar:

1.The Cold-Rolled C Bar can be devided into two kinds, namely common channel steel and light channel steel. The sizes of CR rolled common channel steel range from 5# to 40#. Meanwhile, the channel steel can be divided into cold forming sectional equal channel steel, cold forming sectional unequal channel steel, cold forming inner edge channel steel and outer edge channel steel.

2.The Cold-Rolled C Bar is usually used for arch-itechtural structure, and they could be welded in order to support or hang a vari-ety of facilities. They are also usually used in combination with I beam. The channel steel with sizes under 14# is usually applied to construction engineering, as purline, while the channel steel with sizes above 16# is more likely to be used in building vehicle chassis structure and mechanical structure. Furthermore, the channel steel in sizes above 30# are target at building bridge structure, as tension bar.

3.In a word, the channel steel must possess perfect welding property, riveting property and mechanical property and so on.

Package & Delivery of Cold-Rolled C Bar:

1.The Cold-Rolled C Bar will be packed in bundle with steel wire at each end of every bundle and color marking in order to help the customer to recognize his goods more easily at sight.

2. And the Cold-Rolled C Bar could be loaded into 20ft or 40ft container, or by bulk cargo.If the weight of each bundle reaches more than 3.5 mt, the loading by break bulk cargo should be choosed.When the weight of each bundle reaches less than 3mt, the loading by container should be choosed.

3.As for the transportaion from mill to loading port, the truck will be usually used. And the maximum quantity for each truck is 40mt.

4.All in all, we could do in accordance with customer's request.

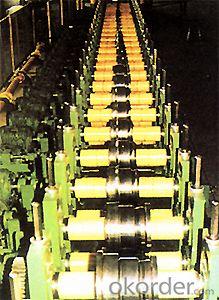

Production Flow of Cold-Rolled C Bar:

1.The steel billet shall be heated in the high temperature furnace.

2. The heated steel billet shall be rolled five to nine times with the aim of shaping the general figure of steel u channel.

3. The rolled steel channel should be put onto the cooling bed to make the temperature low.

4. The Cold-Rolled C Bar should be straighted on the straightener.

5. The straighted steel u channel will be cut into meters by saw, as per customer's requirements.

6. At the last part of production, the channel steel must be tested in order to confirm that the finished products are completely free from crack, pore, slag, scab or fold on the surface.

- Q: Can steel channels be used for pedestrian bridges?

- Indeed, pedestrian bridges can utilize steel channels. The utilization of steel channels is widespread in the construction of bridges owing to their robustness, longevity, and adaptability. They possess remarkable load-bearing capabilities, thus ensuring the secure passage of pedestrians across the bridge. It is possible to tailor the design and fabrication of steel channels to meet specific bridge necessities, including span length, weight capacity, and aesthetic considerations. Furthermore, steel channels exhibit resilience against harsh environmental conditions, rendering them suitable for open-air pedestrian bridges that may be subjected to various weather elements. On the whole, due to their structural soundness and capacity to provide a secure and dependable crossing for pedestrians, steel channels remain a favored option in the construction of pedestrian bridges.

- Q: What is the weight of a steel channel?

- The weight of a steel channel depends on various factors such as its dimensions and thickness. Steel channels are typically measured in terms of their weight per foot or weight per meter. To determine the weight of a steel channel, you would need to know its dimensions, including the height, width, and thickness. By using the appropriate formula or consulting a steel weight chart, you can calculate the weight of a steel channel.

- Q: Can steel channels be used in curved designs?

- Yes, steel channels can be used in curved designs. They can be bent or curved to fit the desired shape, making them suitable for various structural applications that require curved designs.

- Q: What are the maximum span lengths for steel channels?

- The maximum span lengths for steel channels depend on various factors such as the size and shape of the channel, the material grade, the load it is subjected to, and the desired deflection criteria. Generally, steel channels can have span lengths ranging from a few feet to several hundred feet. For smaller steel channels, such as C-shaped or U-shaped channels, the maximum span lengths typically range from 6 to 20 feet. These channels are commonly used for light structural applications, framing, or as support members in building construction. Larger steel channels, such as those used in heavy-duty industrial applications or as primary structural members, can have much larger span lengths. These channels are designed to withstand heavier loads and longer spans. In such cases, the maximum span lengths can extend to several hundred feet or even more, depending on the specific design requirements and engineering calculations. It is important to note that the maximum span lengths for steel channels should always be determined by a qualified structural engineer or designer who considers all the relevant factors and performs the necessary calculations to ensure the safety and structural integrity of the channel system. This ensures that the channel can effectively support the intended loads without excessive deflection or failure.

- Q: Can steel channels be used for supporting mezzanine floors?

- Indeed, mezzanine floors can be supported by steel channels. In the realm of construction, steel channels are frequently employed due to their robustness and resilience. Their exceptional capacity for bearing substantial loads and withstanding deformation or torsion makes them an ideal choice for providing optimal support to mezzanine floors. Typically, steel channels are combined with other structural elements like beams and columns to establish a strong framework for mezzanine floors. By utilizing steel channels, the structural integrity of mezzanine floors remains intact, allowing them to safely accommodate additional weight, be it storage racks, equipment, or personnel.

- Q: Do steel channels have any specific deflection limitations?

- Steel channels do indeed have specific limits on deflection. The deflection of steel channels, along with other structural members, is influenced by factors such as their material properties, dimensions, and the loads they experience. Building codes and industry standards usually specify the maximum allowable deflection for steel channels. These limits are established based on the concept of serviceability, which ensures that the structure remains functional and safe during normal operation. The deflection restrictions for steel channels can vary depending on the particular application and loading conditions. For instance, in the design of structural steel, the deflection limits for beams and columns typically depend on the ratio of span to depth or a predetermined maximum deflection value. Engineers also take into account factors like the intended use, aesthetic considerations, and occupant comfort when determining deflection limitations. For example, in buildings where sensitive equipment or occupant comfort could be affected by vibrations or excessive deflections, stricter deflection criteria may be applied. To determine the specific deflection limitations for steel channels in a given situation, it is important to refer to relevant building codes, industry standards, and engineering guidelines. Professional structural engineers are responsible for ensuring that the design meets these requirements to guarantee the safety and performance of the structure.

- Q: Can steel channels be used for creating storage racks or shelving units?

- Yes, steel channels can certainly be used for creating storage racks or shelving units. Steel channels are known for their strength and durability, making them ideal for supporting heavy loads. They can be easily fabricated and assembled to create sturdy and long-lasting storage solutions. The versatility of steel channels allows for customization and adaptation to specific storage requirements, such as adjustable shelving heights or different rack configurations. Moreover, steel channels can withstand challenging environments, including warehouses, garages, or industrial settings, ensuring the stability and safety of the storage racks or shelving units.

- Q: What are the different types of hangers used for steel channels?

- There are several different types of hangers used for steel channels, including clevis hangers, u-bolt hangers, pipe hangers, and beam clamps. These hangers are designed to provide support and secure the steel channels in various applications, such as construction, plumbing, and electrical installations. Each type of hanger has its own specific design and mounting method to accommodate different channel sizes and load capacities.

- Q: Are steel channels cost-effective?

- Yes, steel channels are generally considered cost-effective. Steel is known for its durability, strength, and longevity, which makes it a reliable material for various construction and industrial applications. Steel channels are designed to provide structural support, distribute loads, and enhance stability in buildings and infrastructure projects. Additionally, steel channels are readily available and can be easily fabricated to meet specific project requirements. While the initial cost of steel may be higher than other materials, its long-term benefits, such as low maintenance and resistance to corrosion, make it a cost-effective choice in the long run.

- Q: Can steel channels be used in manufacturing equipment?

- Manufacturing equipment can indeed utilize steel channels. These steel channels, also referred to as C-channels or U-channels, are highly favored structural elements in various industries owing to their remarkable strength and adaptability. They find frequent application in the creation of machine and equipment frames, supports, and structures. The stability and rigidity provided by steel channels make them well-suited for handling heavy loads and enduring dynamic forces encountered in the manufacturing process. Furthermore, steel channels can be effortlessly welded, bolted, or fastened together, enabling the construction of equipment to be flexible and efficient. In summary, steel channels are an excellent choice for manufacturing equipment, given their durability, strength, and ease of use.

1. Manufacturer Overview

| Location | Tianjin, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 15 Million |

| Main Markets | Southeast Asia; Africa |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 15%-20% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 6,500 square meters |

| No. of Production Lines | 1 |

| Contract Manufacturing | OEM service offered |

| Product Price Range | average |

Send your message to us

Cold-Rolled C Bar

- Loading Port:

- Tianjin Port,China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20Tons m.t.

- Supply Capability:

- 1000 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords