Two Wall Concrete Delivery Pipe for Concrete Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 2000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Two Wall Concrete Delivery Pipe for Concrete Pump

1. Structure of Two Wall Concrete Delivery Pipe for Concrete Pump:

St52 Seamless Pipe: Now More People like use this kind for Truck Pump and Trailer Pump because of the quality is better and it is seamless kind, so this kind pipe is most popular in Middle East Price About 34USD-37USD.

Wear Resistant Pipe: Use for Truck Pump, Wear Resistant Layer is 2.5mm.Through heat treatment way make this pipe more strong (HRC60-62), Using Life: 25,000m³-35,000m³ Price about 65USD-68USD.

Two Wall Pipe: This pipe thickness (2mm+2.5mm), Using Life about 50,000m³-60,000m³

2. Main Features of Two Wall Concrete Delivery Pipe for Concrete Pump:

• High Wear-resistant, long service life, lower cost

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Ensure the supply of ancillary parts

• Our company passed the ISO9000 certification, the product through 3C certification in full compliance with national standards

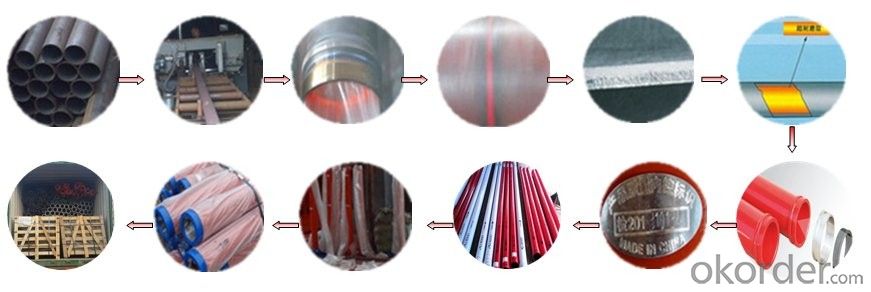

3. Two Wall Concrete Delivery Pipe for Concrete Pump Images:

4. Two Wall Concrete Delivery Pipe for Concrete Pump Specification:

Name | Structure | Specification | Weight | Life time | Impact force | Notched bar impact strength | Max. work press |

Normal wear resistant pipe | Single | DN125*3000mm | 48kgs | 6000 - 8000 | ≥45 | ≥27 | 36 bar |

Economic wear resistant pipe | Single | DN125*3000mm | 45kgs | 18000 - 22000 | ≥47 | ≥28 | 93 bar |

Construction wear resistant pipe | Single | DN125*3000mm | 45kgs | 20000 - 25000 | ≥47 | ≥28 | 93 bar |

Diamond wear resistant pipe | Single | DN125*3000mm | 44kgs | 25000 - 35000 | ≥47 | ≥38 | 93 bar |

W12-5 wear resistant pipe | Twin | DN125*3000mm | 43kgs | 50000 - 60000 | ≥ 42 | ≥25 | 59 bar |

W12-8 wear resistant pipe | Twin | DN125*3000mm | 43kgs | 60000 - 80000 | ≥ 43 | ≥25 | 59 bar |

GX350-1 wear resistant pipe | Twin | DN125*3000mm | 44kgs | 80000 - 100000 | - | - | 34 bar |

GX350-2 wear resistant pipe | Twin | DN125*3000mm | 68kgs | 120000 - 150000 | - | - | 76 bar |

Name | Data |

Material | 45MN2/20#/16MN/Q345 |

Thickness | According to customer requirements |

Color | red, white , etc. |

Using life | 20.000m³-80.000m³ |

Weight | 43kg,48kg,69kg |

Length | 1-6m, according to customer requirements |

Model | DN125,DN150 |

Flange | SK/ ZX /FM flange |

Painting | Electrostatic Spraying Epoxy Paint |

Welding | Smooth welding between straight pipes and flanges |

Process | High temperature quenching |

HRC | 65 |

Production Process

5. FAQ:

We have organized several common questions for our clients, may help you sincerely:

①Is your products exported a lot?

We have exported to many, many countries. Every year we ship more than 30 containers of these spare parts. Our main market is in Middle-east, Asia & Africa.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 15 working days can be served.

- Q: What are the basic requirements for the design of mechanical parts?

- 2. stiffnessThe elastic deformation of a component at work does not exceed the allowable limit. This is called the stiffness requirement. Obviously, only when the elastic deformation is too large to affect the working performance of the machine, it is necessary to meet this requirement. For this kind of parts, besides the strength calculation, the stiffness calculation must be done.

- Q: I designed a great bike with my own mechanical design software. Now I keep it in the computer. What I want to ask isHow do you get these components of the same size, give them the money in the factory, and then make them as planned? Give me a clue, such as magnesium alloy, carbon steel, and so on

- As long as there is enough money, everything is easy

- Q: What are the main functions of CAE software commonly used in the design of mechanical products or parts?

- Finite element analysis, structural motion analysis, interference checking, dimensional chain analysis.

- Q: What is the significance of using this "three changes" in mechanical design?

- Standardization is the design of things, do not have any significance of the difference, unified, become standard, is a reference, there are similar can rely on a standard. Like analog to digital conversion, the analog is transformed into a digital quantity that becomes discontinuous, but always satisfactory.Serialization is a product divided into different specifications, used in different needs, to find the corresponding level. It's like a dress. Tall, medium, and short people have to wear it. Products of the same function, the poor, the middle class and the rich, have their own affordable specifications.General purpose is interchangeable, easy to mass production, easy maintenance, once designed, can be used directly.The significance of standardization is to reduce unnecessary diversity.The significance of serialization is to form a routine, along the way, to sort out a category.The significance of generalization lies in the fact that similar situations are used directly and copied.

- Q: How does the Auto CAD menu bar do not have the "mechanical parts design" command?

- Install or load other tools without having them

- Q: Why do the design of mechanical parts (flanges and elbows) be based on the yield limit?

- Hello friends, usually to do the experiment to the material ontology; have tensile, bending, impact, flattening, flaring, cyclamic, normal temperature test 20 degrees Celsius, is 20 degrees Celsius, minus 20 degrees Celsius, the test to the material, to be determined after completion of the test material meets the design requirements. Is the so-called (to yield limit for design basis?)

- Q: Fixture assembly drawings, detailed parts drawings, design instructions, machining processes, integrated cards, and process cards will be added

- This is not difficult, the machining process card, machining process card, as well as fixture design can do it, learning tyrants have done a lot of experience, you can communicate

- Q: their own materials, hope that the older generation can be under the guidance of the younger brother, brother, thank you very much

- Knowledge of material knowledge of machine parts is usually required:1., first learn some basic knowledge, such as material mechanics, theoretical mechanics, metal materials, heat treatment, metallographic, hot processing, cold processing.2. then learn more about your work unit product. Technical data of main components, performances, requirements and common materials.3., online access to the same or similar industry related information.

- Q: Mechanical design, hardness of the workpiece, how to determine, for example, in the drawings, technical requirements of the hardness value how to get?

- If you are engaged in a kind of graduation design, go to the library and borrow some of the heavy tools for your design manual, mechanical, can get the corresponding information in the manual, manual information can be used as the basis,

- Q: In the process of mechanical design, those areas should be designed as fillet and when to design chamfer. These materials can be found in those places, and the title of the book is also OK. Thank you!

- The edges of the non machined surfaces of various castings shall be designed as arc R, and the sharp edge of the lathe shall be chamfered 45 degrees. These are in the design manual, you are new, and when you are free, look at the design manual.

Send your message to us

Two Wall Concrete Delivery Pipe for Concrete Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 2000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords