DN150 Wear-resistant Pipe for Concrete Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 2000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

DN150 Wear-resistant Pipe for Concrete Pump

1. Structure of DN150 Wear-resistant Pipe for Concrete Pump:

Wear Resistant Pipe: Use for Truck Pump, Wear Resistant Layer is 2.5mm.Through heat treatment way make this pipe more strong (HRC60-62), Using Life: 25,000m³-35,000m³ Price about 65USD-68USD.

2. Main Features of DN150 Wear-resistant Pipe for Concrete Pump:

• High Wear-resistant, long service life, lower cost

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Ensure the supply of ancillary parts

• Our company passed the ISO9000 certification, the product through 3C certification in full compliance with national standards

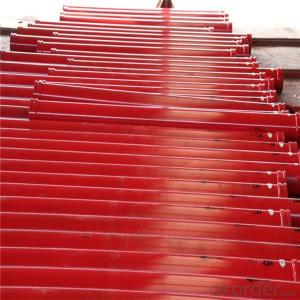

3. DN150 Wear-resistant Pipe for Concrete Pump Images

4. DN150 Wear-resistant Pipe for Concrete Pump Specification

Name | Structure | Specification | Weight | Life time | Impact force | Notched bar impact strength | Max. work press |

Normal wear resistant pipe | Single | DN125*3000mm | 48kgs | 6000 - 8000 | ≥45 | ≥27 | 36 bar |

Economic wear resistant pipe | Single | DN125*3000mm | 45kgs | 18000 - 22000 | ≥47 | ≥28 | 93 bar |

Construction wear resistant pipe | Single | DN125*3000mm | 45kgs | 20000 - 25000 | ≥47 | ≥28 | 93 bar |

Diamond wear resistant pipe | Single | DN125*3000mm | 44kgs | 25000 - 35000 | ≥47 | ≥38 | 93 bar |

W12-5 wear resistant pipe | Twin | DN125*3000mm | 43kgs | 50000 - 60000 | ≥ 42 | ≥25 | 59 bar |

W12-8 wear resistant pipe | Twin | DN125*3000mm | 43kgs | 60000 - 80000 | ≥ 43 | ≥25 | 59 bar |

GX350-1 wear resistant pipe | Twin | DN125*3000mm | 44kgs | 80000 - 100000 | - | - | 34 bar |

GX350-2 wear resistant pipe | Twin | DN125*3000mm | 68kgs | 120000 - 150000 | - | - | 76 bar |

5. FAQ

We have organized several common questions for our clients, may help you sincerely:

①Is your products exported a lot?

We have exported to many, many countries. Every year we ship more than 30 containers of these spare parts. Our main market is in Middle-east, Asia & Africa.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 15 working days can be served.

6. Why choose us

• We are a comprehensive manufacturing and trading company.

• Our company is one of the biggest manufacturing and trading companies in China.

• We have been specialized in producing concrete pump spare parts and specialized in producing all kinds of concrete pump parts. As Concrete Pump Pipe, Concrete Pump Elbow, Concrete Pump Rubber Hose, Concrete Pump Wear Plate, Concrete Pump S Valve, Concrete Pump Piston and so on.

• We are famous for our superior quality, competitive prices, first-class craftworks, safe package and prompt delivery.

• We have been supplying concrete pump parts for SCHWING, PUTZMEISTER, SANY, CIFA, KYOKUTO, ZOOMLION for 10 years, so we can promise you the quality and best price.

- Q: What exactly is mechanical design?

- Mechanical design (machine, design),According to the requirement of the mechanical structure, working principle, motion, force and energy transfer, the various parts of the material and shape size and lubrication methods for design, analysis and calculation and put it into specific description as a basis for the manufacturing process.

- Q: Does the SolidWorks mechanical design engineer paint parts individually or draw parts in an assembly?

- In the overall design of the product, can put each parts of a product are designed, then get the assembly components, after assembly to check whether all parts of the design meets the requirements, whether interference exists, if you need to modify, change are separate parts, and then in the assembly test again until the end, fully meet the design requirements. Since the whole process is down (component), it is impossible to plan the product from the very beginning, and how many parts of the product can be determined only after all the parts have been completed. This method will be modified because there is no prior to the careful planning and effective. This bottom-up design can be used in the case of ready-made products, and in the case of a single product range. But in the new product design or product series rich and changeful circumstances, it seems very inconvenient.TOP-DOWN design refers to the analysis of the finished product, and then down design. The main frame of products as the main component, and the product is decomposed into components, sub assemblies, and then identifies the main component element and its related characteristics, finally understand the relationship between components and internal components, and to evaluate the product assembly. With this information, you can plan and design and grasp the overall design intent in the model.It can manage large components, but also can effectively grasp the design intent, make a clear organizational structure, not only can quickly transfer the design information, in the same design group to achieve the purpose of sharing information, can also transfer the same design information in the design team between different, to the purpose of cooperative combat. Thus, in the early stages of design, through rigorous communication management, can make different design departments synchronous product design and development.

- Q: What are the key factors in designing mechanical parts?

- 2- rationality. Also to the shaft, for example, the outer diameter tolerance depends on what things, such as with bearings, it must be in accordance with the requirements of the base hole design, that is, in accordance with the diameter tolerance of bearings to determine the diameter tolerance.

- Q: Where are the machine parts designed to be finished?

- To the mechanical processing plant ah, there are many machinery processing plants are based on the processing of parts to others to survive, and our products are parts of those machinery factory processing

- Q: Write the XX in the code for the detail column of the assembly drawingThe company's standard clerk says that the standard number or pattern code can only be used in the code bar. The part XX of my presentation is a part of the assembly drawing, which is a non-standard part. I wonder what standard to fill in Is it the material standard? But the material, Q235B, has been written in the material column.

- Agree upstairsYou write that part of your code ah, is their own parts produced by the company to write the parts of the drawing number, is the procurement of non-standard parts, the supplier to write the parts number.

- Q: Turn around the mechanical design class girls, and how to return to this industry?

- Remember the relevant knowledge of mechanical design, and find relevant work directly. Do not remember from the clerk first and so on

- Q: How to write the machining process design of machine parts?

- The so-called processing technology, that is: the processing of each process, the processing required to what extent?. If the text is not clear, you can draw the technical drawings to illustrate.

- Q: Such as title, I am mechanical design, manufacture and automation professional, learning is mechanical design and manufacturing direction, want to PubMed, want to test automation, that is, control, and so on, not purely design and manufacture. Because I do not understand this profession, I would like to consult your predecessors and professionals, I hope you can put forward valuable opinions, under the grateful, put the rest of the pressure on ~ ~ wait for an expert to appearI qq:334175606, I hope to give advice to the professional master ~ ~ ~ also can make a friend ~ ~!

- The interests of postgraduate exams in the machinery industry are not very greatTo PubMed, it is best to change the professionI graduated from mechanical design,I graduated from graduate school for 1 years. I graduated four years agoTheir wages are not as high as mineThe reason is simple1, the machinery industry, experience is more important, more than three years of experience is often more important than academic qualifications2, starting point and pressure pointThe current stall in the machinery industry is undergraduate 3K, salary 3 years of 6K, 10 years is less than 10KGraduate 4K, work within 10 years is less than 10KThe starting point is a little different, one is higher than a high 1K, but you have to consider people of the same ageWhen you graduate with three years of work experience, the study pays less than your peers, but after years of work, the salary is basically the same

- Q: What kind of software is used in the design of machine parts?

- Mechanical parts design, using UG. SolidWorks is not recommended. It's easy to learn, but not powerful.

- Q: In the process of mechanical design, those areas should be designed as fillet and when to design chamfer. These materials can be found in those places, and the title of the book is also OK. Thank you!

- The edges of the non machined surfaces of various castings shall be designed as arc R, and the sharp edge of the lathe shall be chamfered 45 degrees. These are in the design manual, you are new, and when you are free, look at the design manual.

Send your message to us

DN150 Wear-resistant Pipe for Concrete Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 2000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords