concrete pump elbow two layer wear resistant

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product parameters:

Name | Material | Specification | Weight | Common life time | Life tine for two end parts | Max work pressure |

Normal bend | ZG40Mn2 | DN125R27590° | 16kgs | 6000-8000m³ | 1000-3000m³ | 126 bar |

Wear-resistant bend | Mn13-4 | DN125R27590° | 16.5kgs | 20000-25000m³ | 2000-7000m³ | 132 bar |

Twin wall bend | Cr20NiCu1Mo+G20 | DN125R27590° | 15kgs | 60000-80000m³ | 20000-30000m³ | 91 bar |

Twin wall bend | GX350+G20 | DN125R27590° | 15kgs | 80000-150000m³ | 40000-50000m³ | 98 bar |

Product Specifications Model:

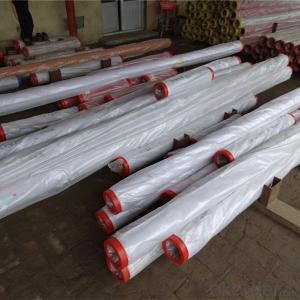

Packaging and transport:

No.1 Export standard packing

No.2 Seaworthy packing

No.3 other ways or according to the customer demand

Why choose us:

1. We are a comprehensive manufacturing and trading company.

2. Our company is one of the biggest manufacturing and trading companies in China.

3. We have been specialized in producing concrete pump spare parts for 10 years and specialized in producing all kinds of concrete pump parts. As Concrete Pump Pipe, Concrete Pump Elbow, Concrete Pump Rubber Hose, Concrete Pump Wear Plate, Concrete Pump S Valve, Concrete Pump Piston and so on.

4. We are famous for our superior quality, competitive prices, first-class craftworks, safe package and prompt delivery.

5. We have been supplying concrete pump parts for SCHWING, PUTZMEISTER, SANY, CIFA, KYOKUTO, ZOOMLION for 10 years, so we can promise you the quality and best price.

- Q: What are the basic requirements for the design of mechanical parts?

- (1) to avoid the requirement of failure in the scheduled life period1. strengthThe residual parts in the work break or do not allow the deformation of insufficient strength of subordination. The above failure forms shall be avoided for any part other than those intended for timely destruction in the safety device. Therefore, the proper strength is the basic condition that must be satisfied when designing a part.

- Q: What exactly is mechanical design?

- Mechanical design (machine, design),According to the requirement of the mechanical structure, working principle, motion, force and energy transfer,

- Q: Does the SolidWorks mechanical design engineer paint parts individually or draw parts in an assembly?

- Either way, in actual work, the two approaches may alternate.If you do is mechanism design, may be other assembly references, can consider each part separately draw, so in the future by other assembly references when good maintenance, no loss of reference.If you do need to consider other parts of the related parts, such as the appearance of the skin, a variety of sports organizations, etc., can be considered to create parts in the assembly, can avoid some mistakes when combined with other parts. However, it is still recommended that you minimize the external reference in the assembly and make the key features that require external reference, and that the rest of the features are still done in an independent part manner.

- Q: What are the main functions of CAE software commonly used in the design of mechanical products or parts?

- Finite element analysis, structural motion analysis, interference checking, dimensional chain analysis.

- Q: How does the Auto CAD menu bar do not have the "mechanical parts design" command?

- 1, will download the atuoCAD mechanical design package unpacked to atuoCAD20** installation directory.2, access to atuoCAD - tools - Options - files - the path to adding atuoCAD mechanical design packages to support file search paths.3, enter the "custom" tool - - - "transmission interface, select the main CUI file in the box at the top of the left column, the choice of transmission interface (acad.cui); the box open at the top of the mechanical design package transmission interface on the right side of the column selection, selection of mechanical design: inside the package.Cui file, start menu items you can see, the design of mechanical parts in the following.4. Expand the menu items in the left and right columns, and drag the design of the machine parts in the right column to the end of the menu item in the left column, and click the Save button at the top of the left column. Click apply to confirm!5, in the command line "menu", select "Support" under the acad.CUI file open, you will see the machine parts design menu hung up!

- Q: In mechanical design, what is the significance of drawing 3D drawings?.

- Advantages: first, look at the intuitive ah, design some complex parts and components, do not express several views.After assembly, the parts can be checked for size. And whether or not to interfere.Three, the software has powerful functions, such as calculation of volume, weight, force analysis and so on, these are two-dimensional software can not compare.

- Q: their own materials, hope that the older generation can be under the guidance of the younger brother, brother, thank you very much

- 4. secondly, need to know these things into the product planning (or product itself), making the product form, content and behavior, can become useful, desirable, and feasible in economy and technology.5. usually the design requires originality and mechanical design is more improved and the use of existing conclusions. This requires the mechanical designer must understand the machining process.6., the processing technology is a very practical technology, can only operate by their own hands, it is possible to have experience and understanding of the technology. There is no shortcut. It is impossible to get inspiration through books.7., this is my experience for more than 40 years.

- Q: What is the design procedure of mechanical parts urgently ah?!

- 5. assembly and parts diagram design. According to the structure and size of parts assembly sketches to determine the complete assembly and parts diagram design. (according to the plan to determine the main dimensions, structure design, parts drawing, sorting out the map) four, as the case with technical documentation requirements, design and coding machine calculation manual, manual, standard parts list, purchased parts list, etc. in the conditions of acceptance in the design process, such as a link the problem is feasible or not, need to return to revise the previous design, until the problem is solved. Sometimes, for this reason, even the whole project has to be knocked over. Therefore, the mechanical design process is an iterative process. (standard and outsourcing parts arrangement, specification preparation, acceptance documents

- Q: Good mechanical design or good mechanical manufacturing?

- generally refers to some large machinery, such as CNC grinding tools and so on, need to do it yourself, go to practice;

- Q: Mechanical design, hardness of the workpiece, how to determine, for example, in the drawings, technical requirements of the hardness value how to get?

- If you are engaged in a kind of graduation design, go to the library and borrow some of the heavy tools for your design manual, mechanical, can get the corresponding information in the manual, manual information can be used as the basis,

Send your message to us

concrete pump elbow two layer wear resistant

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords