High Pressure Concrete Pump Wear Resisting Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 2000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Pressure Concrete Pump Wear Resisting Pipe

1. Structure of High Pressure Concrete Pump Wear Resisting Pipe:

Wear Resistant Pipe: Use for Truck Pump, Wear Resistant Layer is 2.5mm.Through heat treatment way make this pipe more strong (HRC60-62), Using Life: 25,000m³-35,000m³ Price about 65USD-68USD.

2. Main Features of High Pressure Concrete Pump Wear Resisting Pipe:

• High Wear-resistant, long service life, lower cost

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Our company passed the ISO9000 certification, the product through 3C certification in full compliance with national standards

3. High Pressure Concrete Pump Wear Resisting Pipe Images:

4. High Pressure Concrete Pump Wear Resisting Pipe Specification:

Name | Structure | Specification | Weight | Life time | Impact force | Notched bar impact strength | Max. work press |

Normal wear resistant pipe | Single | DN125*3000mm | 48kgs | 6000 - 8000 | ≥45 | ≥27 | 36 bar |

Economic wear resistant pipe | Single | DN125*3000mm | 45kgs | 18000 - 22000 | ≥47 | ≥28 | 93 bar |

Construction wear resistant pipe | Single | DN125*3000mm | 45kgs | 20000 - 25000 | ≥47 | ≥28 | 93 bar |

Diamond wear resistant pipe | Single | DN125*3000mm | 44kgs | 25000 - 35000 | ≥47 | ≥38 | 93 bar |

W12-5 wear resistant pipe | Twin | DN125*3000mm | 43kgs | 50000 - 60000 | ≥ 42 | ≥25 | 59 bar |

W12-8 wear resistant pipe | Twin | DN125*3000mm | 43kgs | 60000 - 80000 | ≥ 43 | ≥25 | 59 bar |

GX350-1 wear resistant pipe | Twin | DN125*3000mm | 44kgs | 80000 - 100000 | - | - | 34 bar |

GX350-2 wear resistant pipe | Twin | DN125*3000mm | 68kgs | 120000 - 150000 | - | - | 76 bar |

Name | Data |

Material | 45MN2/20#/16MN/Q345 |

Thickness | According to customer requirements |

Color | red, white , etc. |

Using life | 20.000m³-80.000m³ |

Weight | 43kg,48kg,69kg |

Length | 1-6m, according to customer requirements |

Model | DN125,DN150 |

Flange | SK/ ZX /FM flange |

Painting | Electrostatic Spraying Epoxy Paint |

Welding | Smooth welding between straight pipes and flanges |

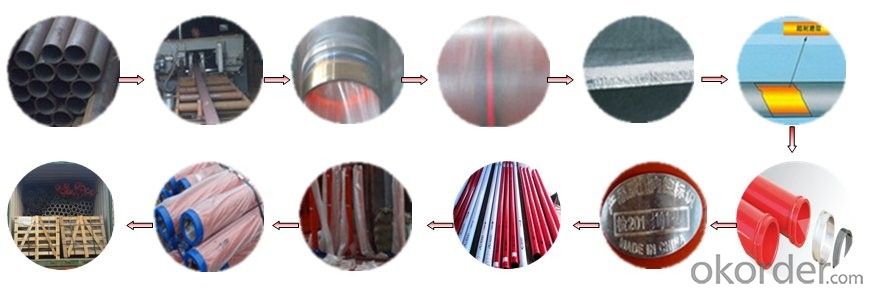

Process | High temperature quenching |

HRC | 65 |

Production Process

5. FAQ:

We have organized several common questions for our clients, may help you sincerely:

①Is your products exported a lot?

We have exported to many, many countries. Every year we ship more than 30 containers of these spare parts. Our main market is in Middle-east, Asia & Africa.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 15 working days can be served.

- Q: 3D MAX must set motion for each object. Is there a 3D mechanical design software that can simulate the mechanical movement of the parts?As long as the specified object is motor, coupling, chain, gear, into the simulation, the three-dimensional map of the motor shaft will rotate, and drives the coupling, keys, gear for the corresponding movement, rather like 3D Max that is the true state of motion to each object design movement performance of this machine combination?

- Suggest or use 3D bar, software use miscellaneous bad

- Q: I designed a great bike with my own mechanical design software. Now I keep it in the computer. What I want to ask isHow do you get these components of the same size, give them the money in the factory, and then make them as planned? Give me a clue, such as magnesium alloy, carbon steel, and so on

- As long as you design the materials used in the car, the market is good to buy, it is easy to find people, like magnesium alloy, I guess a little difficult

- Q: I am an ordinary graduate, two jobs to me, one is non-standard automatic design work, but the first half of the assembly in the workshop, and then to design. There is also a mechanical component CAD draftsman. After that, you can do part design. May I ask which job will have a future for you?

- The design of non-standard automation is promising, and the work of the CAD draftsman is only a small part of the non-standard automation work.

- Q: Turn around the mechanical design class girls, and how to return to this industry?

- Remember the relevant knowledge of mechanical design, and find relevant work directly. Do not remember from the clerk first and so on

- Q: I'm going to learn 3D design. I used to just CAD.Excuse me, is it good to learn PRO-E or SOLIDWORK?I mainly used in product design (such as sheet metal parts, machining parts and plastic parts, etc.) is used to design the mould.Also, you can download the best Chinese version of these two software from the Internet, please ask friends about the locationUrgently...

- These two can, there is a director, according to the domestic general situation, usually PROE use more, exchange more convenient, as long as there is a three-dimensional software with skilled, no matter that can be.

- Q: What are the main principles of mechanical principles and mechanical parts design?

- 4. weight requirements, often in the hands of the parts required lightweight, in the case of mechanical strength to meet the choice of small proportion of materials;5. service life requirements are temporary or long-term use, intends to use a year or 10 years?6., the influence of environmental temperature, environmental temperature changes will affect the expansion of parts;

- Q: What software is best for designing mechanical parts?

- The original is using autoCAD, and now popular with SOILDWORKS three-dimensional software, intuitive, easy to use, but also CAD function

- Q: What do engineers need to learn from mechanical design as an electronic hardware engineer?

- In recent years, electronic technology, optical technology has been rapid development, these instruments need photoelectric conversion system, electronic system, precision machinery system together, in order to realize the function of, it is a challenge to the traditional mechanical design, at the same time precision machinery design came into being.

- Q: What kind of software is used in the design of machine parts?

- Mechanical parts design, using UG. SolidWorks is not recommended. It's easy to learn, but not powerful.

- Q: Mechanical design of various parts of the hardness value of how to determine?.

- You send out the request and I'll help you get it! Upstairs answer obvious mistakes, such as 45 steel, the best performance in 39-44HRC, but domestic heat treatment and foreign heat treatment level there are differences, the same hardness, foreign countries are several times more durable than the domestic!

Send your message to us

High Pressure Concrete Pump Wear Resisting Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 2000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords