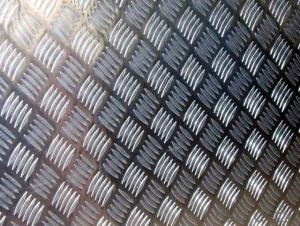

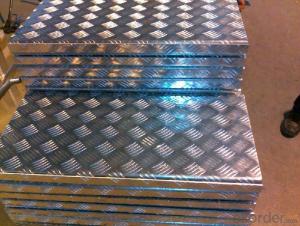

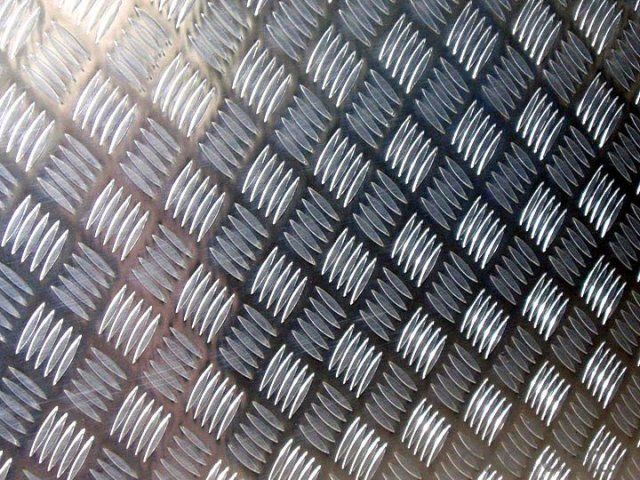

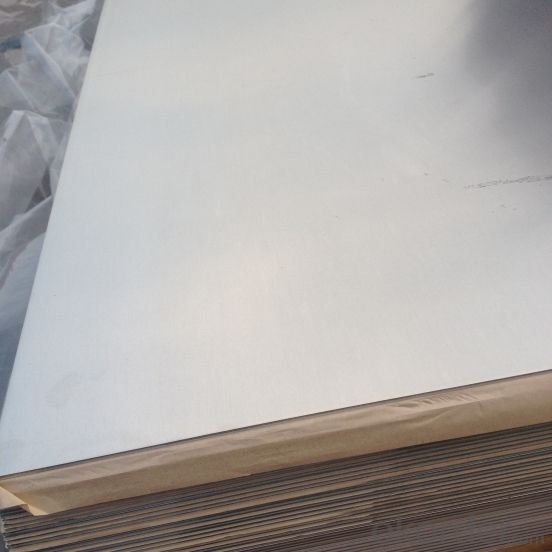

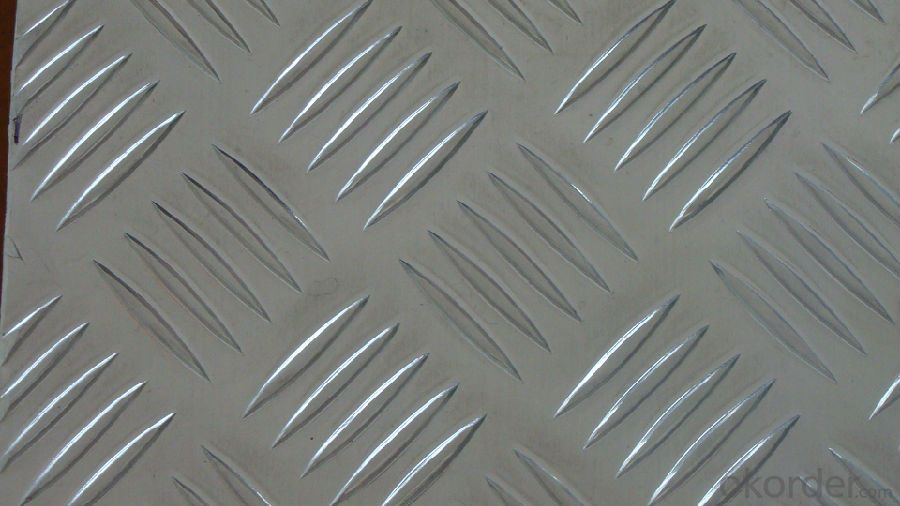

Aluminum Roof Sheets India - Two Bar Diamond Aluminum Tread Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

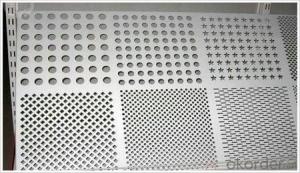

You Might Also Like

Specification

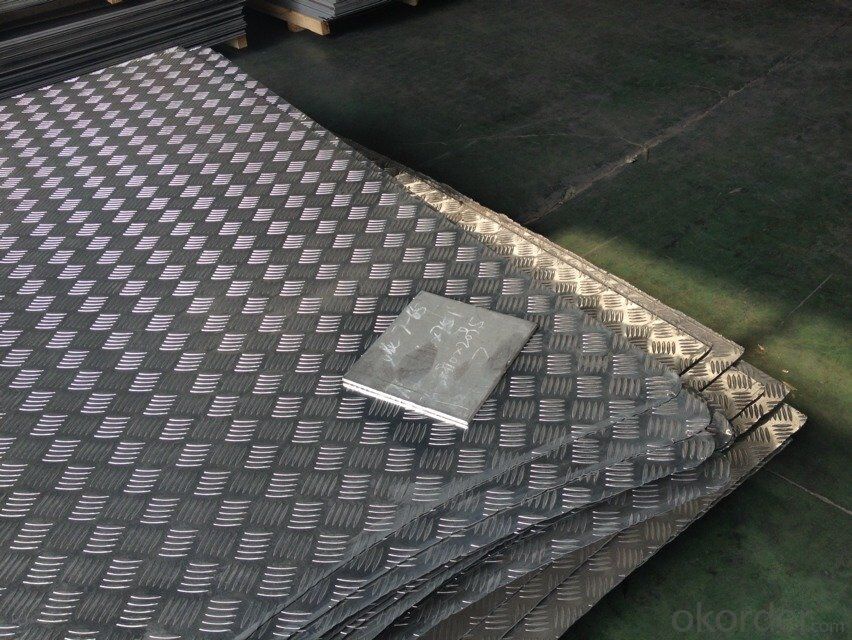

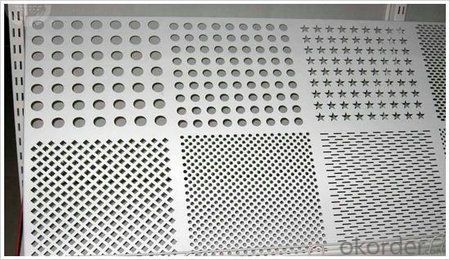

aluminum chequered plate are widely usd for bus, cars and shipping vessel as the floor....

Aluminum tread plate is also called anti-slide aluminum sheet which is widely used in manufacturing vehicles, ships, washing machines, refrigerator shell, etc.

Specification:

Alloy: 1050, 1060, 1100, 3003, 3105, 5052

Temper: O, H12, H14, H16, H18, H22, H24, H26, H32

Thickness: 1.0~10mm

Width: 1000~1600mm

Length: 1000~6000mm

Packing:

One roll in an individual box or printed PP bag

Certain quantities in a standard carton

Depends on customer’s request

Service

1. We have the good and professional team, have a good after-sales service.

2. Accept any drawings or your samples to develop new product.

3. Offer relateive technical support,quick response,all your inquire will replied within 24 hours.

4. OEM, buyer design, buyer label services provided.

5. Have the certification of ISO 9001, SGS.

6. Special discount and protection of sales area provided to our distributor.

FAQ

Q1:Do you provide sample? How many days will samples be finished?

Free samples will be provided if needed, but customers should undertake shipping cost or freight charges, samples will be finished in 5-7days

Q2: Can we visit your factory?

Welcome to our factory at any time.

Q3: Complaint solving process

Finding your salesman—Salesman provide you the solution (If it’s our responsibility, we will resend substitutes or return money or provide discount for your next order, etc.; If it’s shipping company’s responsibility, we will also help you until the problem is resolved.) —If salesman can’t solve your problem, please call our manager .

Q4: Delivery time

3~30working days after confirming the payment. If the order is urgent, we will push our workers to finish in advance.

Q5: What's your MOQ?

Normally 8MT are requested as the minium order quantity ,we shall give

additional instructions in special circumstances.

Q6: What are the terms of payment and currencies do you accept?

T/T or L/C is accepted, currently we appreciated your payment through

USD,EUR, RMB

Q7: Do you accept customized orders?

Yes, we do. Your customized orders are always welcomed. Please kindly offer us your samples or drawings, so that we can customize the products according to your preferences. About any further detail, please feel free to contact us.

Q8: What information should I let you know if I want to get a quotation?

Your detailed requirements regarding the products's dimensions, including shape, thickness, top out (length*width*height), and your order quantity are highly appreciated if you want further information about our quotation

Q9: How about the mass production?

The lead time of mass production depend on quantity, usually 25-30days (20FT) .

- Q: What are the limitations of using aluminum sheet?

- There are several limitations to using aluminum sheet. Firstly, it has a lower strength-to-weight ratio compared to other materials like steel. This means that aluminum sheets may not be as strong and durable in certain applications. Additionally, aluminum is prone to corrosion, especially in harsh environments, so proper protective coatings or treatments are necessary. Aluminum sheets also have limited formability compared to materials like steel, which can impact their use in certain complex shapes or designs. Lastly, aluminum sheets can be more expensive than other materials, which may affect their affordability in certain projects.

- Q: Does anyone know how to polish aluminum on a motorcycle that isn't too expensive to do?

- MOTHERS okorder one to do the polishing....then use a fresh one to buff the aluminum. Trust me on this one.....this is the ONLY polish I use on custom bikes.....with this stuff, you can make aluminum look almost like chrome!!!

- Q: Is aluminum sheet resistant to UV rays?

- Yes, aluminum sheet is resistant to UV rays.

- Q: Are aluminum sheets resistant to saltwater corrosion?

- Yes, aluminum sheets are generally resistant to saltwater corrosion. Aluminum has a natural ability to form a protective oxide layer when exposed to air or water, including saltwater. This oxide layer acts as a barrier, preventing further corrosion and protecting the underlying metal. Additionally, aluminum is lightweight and durable, making it a popular choice for various marine applications such as boats, shipbuilding, and offshore structures. However, it is important to note that the resistance to saltwater corrosion can vary depending on the specific alloy and surface treatment of the aluminum sheets. Therefore, proper selection of the appropriate alloy and protective coatings can further enhance the corrosion resistance of aluminum sheets in saltwater environments.

- Q: Can aluminum sheets be hydroformed?

- Yes, aluminum sheets can be hydroformed.

- Q: Would you please tell me what putty to use on the aluminium board, what kind of putty, and the painting process?

- Applied atomic ash.Consider adding an interface agent, that is, applying an interfacial agent on the aluminum plate, and then applying a topcoat on the interface agent after drying.You can also consider adding primer or putty, and then spray paint.In summary, adhesion of the topcoat is reinforced with an agent.

- Q: What are the different cutting tools used for aluminum sheets?

- There are several cutting tools that can be used for aluminum sheets. 1. Circular Saw: A circular saw with a carbide-tipped blade can be used to cut aluminum sheets. It is important to use a blade with fine teeth to ensure a clean and smooth cut. 2. Jigsaw: A jigsaw equipped with a metal-cutting blade can also be used to cut aluminum sheets. This tool allows for more intricate cuts and curves. 3. Bandsaw: A bandsaw with a fine-toothed blade is another option for cutting aluminum sheets. It provides a straight and precise cut, making it ideal for larger or thicker sheets. 4. Shears: Electric or manual shears can be used to cut aluminum sheets. They are particularly useful for straight cuts and can achieve a clean finish. 5. Plasma Cutter: A plasma cutter can be used for cutting aluminum sheets, especially for thicker materials. It uses high-temperature plasma to melt through the metal, resulting in a precise and efficient cut. 6. Laser Cutter: Laser cutting machines are commonly used for cutting aluminum sheets. They produce a high-powered laser beam that melts and vaporizes the material, allowing for precise and intricate cuts. It is important to wear appropriate safety gear, such as gloves and goggles, when using any of these cutting tools. Additionally, choosing the right tool depends on the thickness of the aluminum sheet and the desired cut. It is recommended to consult a professional or refer to the manufacturer's guidelines for the specific tool being used.

- Q: Can aluminum sheets be roll-formed?

- Yes, aluminum sheets can be roll-formed. Roll forming is a process in which a continuous strip of metal, in this case, aluminum, is fed through a series of rollers to gradually shape it into a desired profile or shape. Aluminum is an ideal material for roll forming due to its malleability and ductility, allowing it to be easily bent, curved, and formed into various shapes. It is commonly used in industries such as construction, automotive, and aerospace for applications that require lightweight yet durable components.

- Q: I've heard twice in the past 2 days on ESPN that they think Aluminum bats are dangerous. I disagree with this cause if they were dangerous why would they allow them to use them in college and high school. Isnt that what the BESR certification mean that the bat is safe that the ball isnt going to come off at super high speeds. i just wanted to get your opinion.

- I don't know what they are thinking about unless it is the fact that they are lighter and a given person can create higher bat speed which translates to harder hit balls. However I don't think there's that much difference from what I've observed. I have seen 2 of them come apart at games my boys played in but nobody got hurt.

- Q: HEY HEY HEY guys its me agian and during today and the six week hoiday i'm gonna be askin a LOT I mean A-LOT ok so firstly I want to ask about drill bit you see as a willing studend who is enginenerring and just now in sience (so please ansewr quikly) what properites does an aluminium oxide drill bit have alot more questions after this one are going to be veary youtube and game related such as what do you guys want me to tweet pewdiepie on fridays whith pewdiepie and so on thanks and bye!!!!!!

- It acts a lubricant.

Send your message to us

Aluminum Roof Sheets India - Two Bar Diamond Aluminum Tread Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords