Rhombic Form Traveller

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

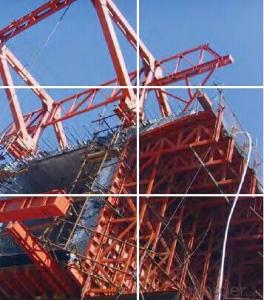

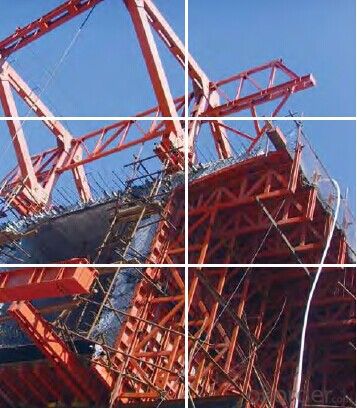

RHOMBIC FORM TRAVELLER

The rhombic form traveller has the advantages of simple structure, clear

stress, big operational space under the main frame, and easy installation

and removal, etc..

The form traveller adopts wheels with bearing while rolling forward which

reduce the frictional resistance greatly during movement; At the same

time, the stainless steel paltes are welded on the rails which reduced

the frictional resistance bewwen the sliding bearing and the rails during

movement. The combination of these reduce the movement cycle of the

form traveler by simple and convinient operation.

In terms of safety, the form traveler is equiped with walking protection

system which guarantee the absolute safety during working. It’s safe, easy

and practical.

● Low gravity of front trancerse beam

● Applicable to large-scale stay-cable cantilever casting bridge with wide bridge deck

● Safe & easy operation, easy fixing, and safty during walking

● Big operational space under the main frame, and easy installation and removal

- Q: What is the meaning of hanging basket in construction

- Refers to the outdoor decoration of the basket.

- Q: I would like to ask you how to sort the hanging basket? What is the front fulcrum hanging basket

- 3, hanging basket construction;4, concrete pouring construction;5, prestressed construction;6, beam body linear control;7, closure section construction and system conversion

- Q: What's the meaning of the main truss in the basket?

- H ngli ng trussThe [brace girder] is composed of a plurality of slats of the web and the two sides of the connection of the girder

- Q: I would like to ask a joint (32m+48m+32m) continuous beam cantilever hanging basket perfusion, each phase of the most reasonable construction cycle is how long (in days), thank you

- How many blocks are designed, and the span is cast with a cantilever? Symmetrical pouring, an average of 4 days a piece of it, the two sets of hanging baskets, Block 0 to see your ability to design their own bar

- Q: In the construction of the bridge hanging basket, the temporary prestressing force is adopted in the closing section

- And then a little bit of clamping pieces will be clamped, according to this repeatedly know that the complete elimination of prestress

- Q: Hanging basket construction must be both sides at the same time construction? Are there any rules? What is the norm?

- There are only two or three workers and simple tools and a small amount of material in the basket, the load is very small, do not require simultaneous construction. JGJ202-2010 "building construction scaffolding safety technical specifications" there is no such meaningless provisions.

- Q: Hanging basket assembly quality control point

- The composition of the basketHanging basket bearing system, bottom formwork system, side formwork system (inside and outside), walking system, rear anchorage system. A hanging basket is made up of two triangles, each of which bears the weight of the beam. Taking into account the processing capacity of the construction site, the main beam, the sliding beam, the upper beam and so did not use a reasonable truss structure, and the use of steel structure.

- Q: Hanging basket construction steel binding labor costs a ton of money

- Specific include: including equipment installation, removal, transportation, raw material transportation, loading and unloading vehicles, on-site storage custody

- Q: Construction technology of bridge hanging basket

- D, the crane will be used to bridge the bottom of the bottom of the platform to lift the platform, and with the front sling, and then install the rear sling;D, installing the rear cross member and rear outer belt;E, to the basket to pre pressure to eliminate the plastic deformation, determine the size of elastic deformationF, the installation of internal and external model walking beam and to the 1# position;

- Q: What should be paid attention to in the construction of cast in place box girder of long span bridge hanging basket

- Preventive measures: with good insulation performance wood template (preferably professional manufacturers), have a certain thickness and stiffness of the template surface to be coated with special treatment, release agent, to ensure the quality of cast-in-place concrete.The contents of the above are based on the actual work of the students to meet the problem of finishing, for reference, if there is a problem, please timely communication.

Send your message to us

Rhombic Form Traveller

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords