Triangular Form Traveller in High Quality

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

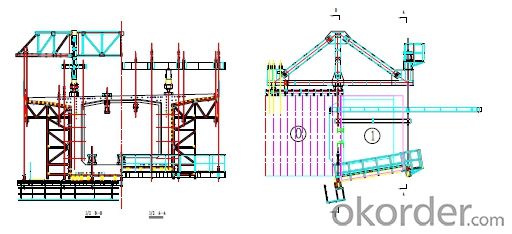

TRIANGULAR FORM TRAVELLER

Trianngular form traveler has the advantages of low gravity of front

trancerse beam, safe & easy operation, easy fixing, and safty during

walking, etc..

During the designing of the form traveller, we always provide

different modes of traction, such as hydraulic pushing mode or

pulling mode, and chain hoist mode, etc. to the constructors for their

choice.

The design of the form traveller could be divided into two types:

external sliding girder and self-moving exteral formwork according to

de construction conditions. When the site condition does not allow

to remove the form traveller at the closure part which have to go

backwards to segment, the second type is suggested.

● Low gravity of front trancerse beam

● Applicable to large-scale stay-cable cantilever casting bridge with wide bridge deck

● Safe & easy operation, easy fixing, and safty during walking

● Big operational space under the main frame, and easy installation and removal

- Q: I am going to the US by car and i know we need to fill a form. But im not sure if we get the form at the boarder or what....

- They will have the forms at the border crossing.

- Q: What is the function of the rain - water hanging basket device in the rainwater collection system

- The initial rainfall will carry a large amount of garbage, such as leaves, sediment and other garbage into the storm sewer system will cause congestion

- Q: I would like to ask a joint (32m+48m+32m) continuous beam cantilever hanging basket perfusion, each phase of the most reasonable construction cycle is how long (in days), thank you

- Continuous beam of a block of the construction period of about 10 days to about 12 days, the 10 day is a bit illegal operation

- Q: Hanging basket dry steel, steel hinge line, how much money a ton. How much money one concrete

- ; bar straightening, processing, assembling, derusting, welding, sleeve connection, transportation, installation, transportation and other material field model and application of reinforced 1533...

- Q: How to evaluate the construction scheme of bridge hanging basket

- For example: 1 you choose the form of hanging basket to meet the design requirements2 is there any difference in the reliability of the bridge design

- Q: T type steel bridge, the river, river on both sides of the main girder by cantilever pouring symmetrical design, no clear requirements,

- In collapsible loess two treatments: two impact rolling compaction than the two function of the sections all dynamic compaction process: first, clear the table; in accordance with the design requirements of playing grid soil deployment design; determine the mechanical compaction function (120 tons of rice and 60 tons of rice)In addition, due to the treatment of the collapsible loess structure, the structural treatment of the first pit excavation with tons of machinery to ensure the safety of the structureIn dealing with the Embankment Compaction Mechanism of soil particle skeleton body: three-phase inter particle pore water gas in the occupied compaction soil particles that re combination of squeezing pore shrinkage soil unit weight increase overall strength increase resulted in dense shape stability improved

- Q: Hanging basket assembly quality control point

- The hanging basket according to the different structures and stress characteristics, divided into parallel truss basket bowstring, hanging basket, triangle hanging basket and basket, mainly in the following triangle hanging basket as an example.

- Q: Hanging basket installation, removal of dangerous source identification

- The first is a potentially dangerous source of energy and material release dangerous, can cause personal injury, property damage or damage to the environment, in the role of the trigger factors can be transformed into the accident location, area, location, space, position, and the position of equipment in a system. It is the essence of a potentially dangerous source or location, is the source of the outbreak of the accident, is the core of the concentration of energy, hazardous substances, where the energy from where the outbreak or outbreak. The hazard sources exist in the identified system, the different system range, and the hazard source region. For example, from a national point of view, for dangerous industries (such as oil, chemicals, etc.) a specific enterprise (such as oil refineries) is a dangerous source. From an enterprise system, it may be a workshop, warehouse is a dangerous source, a workshop system may be a device is a dangerous source; therefore, the analysis of risk sources should be carried out according to the different levels of the system.

- Q: Hanging basket type PCB turnover vehicles generally have many dimensions, how many baskets can be hung

- . The number of hanging baskets up to 16, ranging from 24. Hanging basket size: 415 * 285 * 205MM, slot width 2MM, slot depth 4.5MM, slot spacing 7MM, hanging basket type PCB turnover car use lightweight, convenient, can be used for all kinds of warehouse, production site and other occasions

- Q: I'm British and traveling to Cuba whats the best form of travelers cheque to buy?

- well i dont know much about cuba even thow im from the caribbean, i think they use their own money, dont know if pounds gonna work they, if i where you i would get some us money it can be spend anywhere in the caribbean and since pounds is worth more than us dollars you would be in good shape anyway hope you know spanish good luck and send me a post card.

Send your message to us

Triangular Form Traveller in High Quality

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords