High-end Triangular Form Traveller with Big Operational Space

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

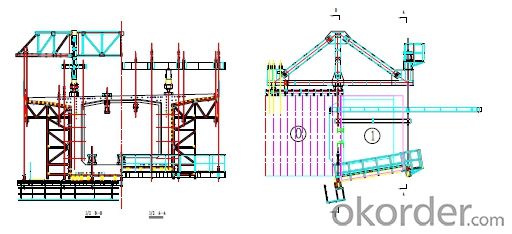

TRIANGULAR FORM TRAVELLER

Trianngular form traveler has the advantages of low gravity of front

trancerse beam, safe & easy operation, easy fixing, and safty during

walking, etc..

During the designing of the form traveller, we always provide

different modes of traction, such as hydraulic pushing mode or

pulling mode, and chain hoist mode, etc. to the constructors for their

choice.

The design of the form traveller could be divided into two types:

external sliding girder and self-moving exteral formwork according to

de construction conditions. When the site condition does not allow

to remove the form traveller at the closure part which have to go

backwards to segment, the second type is suggested.

● Low gravity of front trancerse beam

● Applicable to large-scale stay-cable cantilever casting bridge with wide bridge deck

● Safe & easy operation, easy fixing, and safty during walking

● Big operational space under the main frame, and easy installation and removal

- Q: What is the meaning of the bridge basket and bridge system

- The construction of the bridge hanging basket is mainly used for continuous beam or continuous rigid frame bridge

- Q: What are the innovative points of hanging basket construction

- Management points:1 the concrete pouring on both sides of the beam should be symmetrical and balanced, and the unbalanced construction load should not be greater than the allowable value;2 concrete should be rapid, continuous construction, in the first pouring of concrete before the first pouring all completed;3 the bottom plate, the web and the roof are symmetrically layered, and the layer thickness should not be greater than 30cm;

- Q: I would like to ask you how to sort the hanging basket? What is the front fulcrum hanging basket

- The key process of hanging basket construction:1, Block 0 (support) frame construction;2, bearing and temporary consolidation system construction;

- Q: What are the key processes of hanging basket construction

- 1, Block 0 (support) frame construction;2, bearing and temporary consolidation system construction;3, hanging basket construction;4, concrete pouring construction;5, prestressed construction;6, beam body linear control;7, closure section construction and system conversion.

- Q: I would like to ask: how to choose the kind of hanging basket? Do their own basket design and production for 2 years, but do is diamond, triangle hanging basket and diamond hanging basket, etc.

- The other is to fit the actual, anyway, so many hanging baskets did not change to the scene. Some even have to cut the injured all over the body...... Heartache.

- Q: After the completion of prestressed tension grouting on the basket can move forward

- [] the hanging basket is a walk along the railway activities scaffolding, hanging basket hanging in the already stretching and anchoring box girder, cantilever casting box girder formwork installation, rebar, pipe installation, concrete pouring, tensioning and grouting work were carried out in the hanging basket. When the construction procedure of a beam section is completed, the hanging basket is lifted, and the beam is moved downwards. Therefore, the hanging basket is not only the space of the construction equipment, but also prestressed tendons before the beam segment of the load-bearing structure, and now large, medium and large buildings use this equipment.

- Q: I would like to ask a joint (32m+48m+32m) continuous beam cantilever hanging basket perfusion, each phase of the most reasonable construction cycle is how long (in days), thank you

- Continuous beam of a block of the construction period of about 10 days to about 12 days, the 10 day is a bit illegal operation

- Q: There are transverse prestressed steel strand in the middle beam, the bridge has longitudinal steel strand, and the vertical line is finished steel. I would like to ask the next three pull sequence

- And then, at the top of the tension plate, the steel strand of the web, and then the residual steel beam of the beam, and finally the vertical finishing steel.

- Q: Hanging basket in the construction of the 2 block construction is also need to press it

- The main points of hanging basket construction:1 the installation elevation of the hanging basket should be in strict accordance with the designed value.2 reserved holes shall be accurate and shall not be allowed to bend.3 the pre tension of the hanging basket should be set according to the design.

- Q: How is the prestressed steel bar in the hanging basket method? Is the length of each section of the tension of the prestressing tendons, or tensioned T - shaped steel beam length of prestressed tendons?

- The general construction of prestressed concrete box girder with cantilever hanging basket construction scheme, the box girder hanging basket, formwork, reinforced after installation, concrete pouring, the concrete reaches the design strength value after tensioning the beam segments each segment between the prestressed tendons (tendons connected according to the design of short or long beam the layout of the beam.) after grouting, demolition template

Send your message to us

High-end Triangular Form Traveller with Big Operational Space

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords