Safty Triangular Form Traveller in China

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

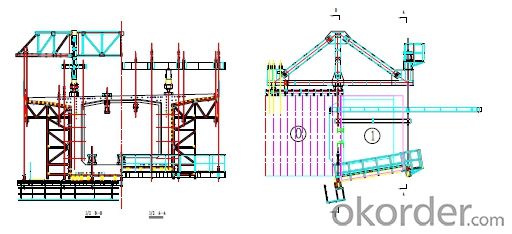

TRIANGULAR FORM TRAVELLER

Trianngular form traveler has the advantages of low gravity of front

trancerse beam, safe & easy operation, easy fixing, and safty during

walking, etc..

During the designing of the form traveller, we always provide

different modes of traction, such as hydraulic pushing mode or

pulling mode, and chain hoist mode, etc. to the constructors for their

choice.

The design of the form traveller could be divided into two types:

external sliding girder and self-moving exteral formwork according to

de construction conditions. When the site condition does not allow

to remove the form traveller at the closure part which have to go

backwards to segment, the second type is suggested.

● Low gravity of front trancerse beam

● Applicable to large-scale stay-cable cantilever casting bridge with wide bridge deck

● Safe & easy operation, easy fixing, and safty during walking

● Big operational space under the main frame, and easy installation and removal

- Q: Car hanging basket, green, yellow different license, according to what standard hang

- Large civilian vehicles: Yellow black;Small civilian vehicles: blue and white;Public security vehicles: white black word, there are red police words;

- Q: There are several construction methods of bridge hanging

- You mean the hanging basket? The hanging basket is divided into a front fulcrum hanging basket and a rear pivot hanging basket.

- Q: What is the length of the bridge hanging basket construction?

- The bridge hanging basket belongs to the cantilever construction, which can only be designed according to the bridge type, the design of the cable and the weight of the block

- Q: Do the Populations Of the Countries of the world really believe that all Americans are Pompous, Arrogant, loud, and demanding, because of the personalities of SOME of those who travel the world. Perhaps some of your opinions are formed because of trips you have made to the States, too. Were you treated rudely while visiting here? Does the Media in your country Help form your opinion of us, or perhaps the Media from our country, that you may have seen. It seems that World opinion of Americans is pretty poor these days, and I am concerned about that. Most of us are pretty good , And some of us are not, just like any other country. I am just wondering about your thoughts.

- Americans USED to be much better hosts then guests. Now we are pretty much crap at each side.

- Q: I'm looking for lowest service charge and also prevention of loss or theft. I know actual Swedish Kronas would be best but is it better to use traveler's cheques or credit ot atm card?Thanks

- I always use my ATM debit card at ATMs to withdraw cash and then I use cash for most purchases. You get a better exchange rate that way, plus your bank will charge you a conversion fee every single time you use your debit card from home instead of one fee for withdrawing 1000 SEK, for example. Sweden is really safe and theft isn't terribly common. If you're worried, you can wear a money belt under your clothes and keep your card and large sums of cash in there. I'm assuming you're a foreigner traveling to Sweden, but maybe I'm wrong.

- Q: Hanging basket construction must be both sides at the same time construction? Are there any rules? What is the norm?

- Please rest assured that the calculation of the load of the bridge structure is huge, just hanging basket this little temporary construction load is not a piece of cake!Only from the point of gravity load on the bridge, there is no problem. But whether the requirements of the construction process, construction organization, or starting or starting from the schedule to rush period, it should be different.

- Q: When hanging blue construction, middle span closure, why must the counterweight

- The carrying capacity of the hanging basket depends on the maximum weight of the cast-in-place section

- Q: Seven techniques of hanging basket

- 10.5. tube. When the concrete is vibrated, we should pay attention to avoid the bellows to prevent the vibration rod from leaking;10.6. to nap. Because of concrete pouring, the surface still paving asphalt concrete, in order to enhance the bonding between the deck and asphalt layer layer of political government must firmly on the concrete surface roughening treatment:10.7. maintenance. After the concrete pouring, maintenance to improve the strength of concrete and prevent the formation of fine cracks, has an important role. Therefore, water conservation should not be less than seven days.

- Q: Composition management of hanging basket

- Compression system: to master the balance of the protection of double guide beam. The system is composed of a pre embedded steel bar and a compression beam, and the force is applied to the box girder section through the double pull rod, and the anti overturning moment is generated to protect the balance of the double guide beam.

- Q: Combined with the hanging basket pouring construction process, the paper puts forward the quality control points and methods of hanging basket continuous casting box girder

- Hanging basket when walking, hanging basket as far as possible to do the same time, the difference between the asymmetric distance between the hanging basket is 5cm;One must be responsible for observing the synchronization of walking, the two person is responsible for observing the operation of the walking anchor beam, the two is responsible for observing the operation of the outer die frame bearing;

Send your message to us

Safty Triangular Form Traveller in China

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords