Stayed-cable Cantilever Traveller

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

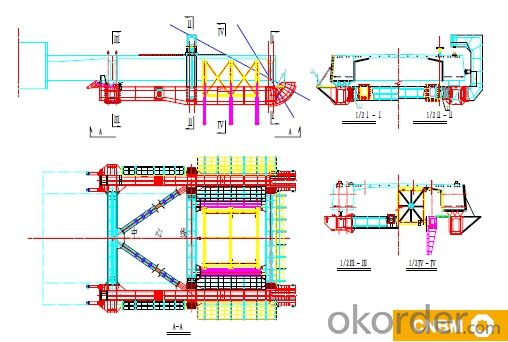

STAYED-CABLE CANTILEVER TRAVELLER

Stayed-cable cantilever traveller is applicable to large-scale stay-cable

cantilever casting bridge with wide bridge deck, heavy and long segment. Most of

the componants concentrates on bottom frame and walking system. It has no main

frame, at the same time, the lift is done by the stay-cable of the bridge. Comparing

with other types, the sigle weight of stayed-cable cantilever traveller is heavier.

●Low gravity of front trancerse beam

●Applicable to large-scale stay-cable cantilever casting bridge with wide bridge deck

●Safe & easy operation, easy fixing, and safty during walking

●Big operational space under the main frame, and easy installation and removal

- Q: Production and installation of hanging basket

- 8..5. fixation. In the process of pouring, the anchor plate is easy to loose 1 shift. Therefore, the screws must be fixed on the head template o8.6. positioning. The positioning of the corrugated pipe should be based on the bottom of the corrugated pipe, according to the curve coordinates of the prestressing tendon in the design.8.7. welding. In the process of pouring the bellows lands will be produced in the floating phenomenon, therefore, the bellows in place, can be tied to a "n" type in steel pipe, welded steel bracket and firmly, spacing is generally 60 cm, bracket welding in the stirrups, stirrup below advance real pad o

- Q: How to define the construction stage of continuous beam bridge hanging basket construction

- Continuous beam Shujing indeterminate structure, can solve the internal force of law

- Q: I would like to ask a joint (32m+48m+32m) continuous beam cantilever hanging basket perfusion, each phase of the most reasonable construction cycle is how long (in days), thank you

- Continuous beam of a block of the construction period of about 10 days to about 12 days, the 10 day is a bit illegal operation

- Q: In the construction of the bridge hanging basket, the temporary prestressing force is adopted in the closing section

- Almost the same procedure. Install jack, Jack extended a distance, not fully stretched

- Q: Summary of the hanging basket construction

- Cable stayed bridge is a bridge deck system, the support system of the bridge, the bridge deck system with stiffening beam, the supporting system is composed of steel wire.In 1956, the Stromsun bridge in Sweden began the apex of the modern cable-stayed bridge. With the development of material science and computer science, a lot of cable-stayed bridges have been built at home and abroad. The cable-stayed bridge has been developed rapidly because of its advantages such as large span, good structural performance, simple construction, easy maintenance, low cost and attractive appearance.

- Q: Hanging basket dry steel, steel hinge line, how much money a ton. How much money one concrete

- Two provide semi-finished steel transport B from the steel processing field will be processed to cantilever at

- Q: How to evaluate the construction scheme of bridge hanging basket

- Hanging basket construction is a more common construction, the expert review is only for some non common problems to discuss the refinement

- Q: Hanging basket construction must be both sides at the same time construction? Are there any rules? What is the norm?

- Hanging basket is hanging on the structure of the tool type scaffolding, its movement by crane or tower crane

- Q: Vertical embedding of hanging basket

- The reserved hole of the hanging basket must also ensure the correct position and the verticality of the reserved hole. The reserved hole pipe should be welded and fixed with steel pipe, which can prevent the concrete from entering the pipe o

- Q: I would like to know that each piece of the construction of the hanging basket is connected by way of the whole as a whole, I always think of each section is a section of tension.As you said, the steel strand is the length of the whole beam, but how to form the whole concrete?

- Each section of the pouring, the prestressed pipe to stay in that, when the tension, only pull the section of prestressed reinforcement. Those who like long, without tension will not wear.

Send your message to us

Stayed-cable Cantilever Traveller

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords