Polyester Geogrid/ Fiberglass Geogrid/ PP Geogrid for Dam

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

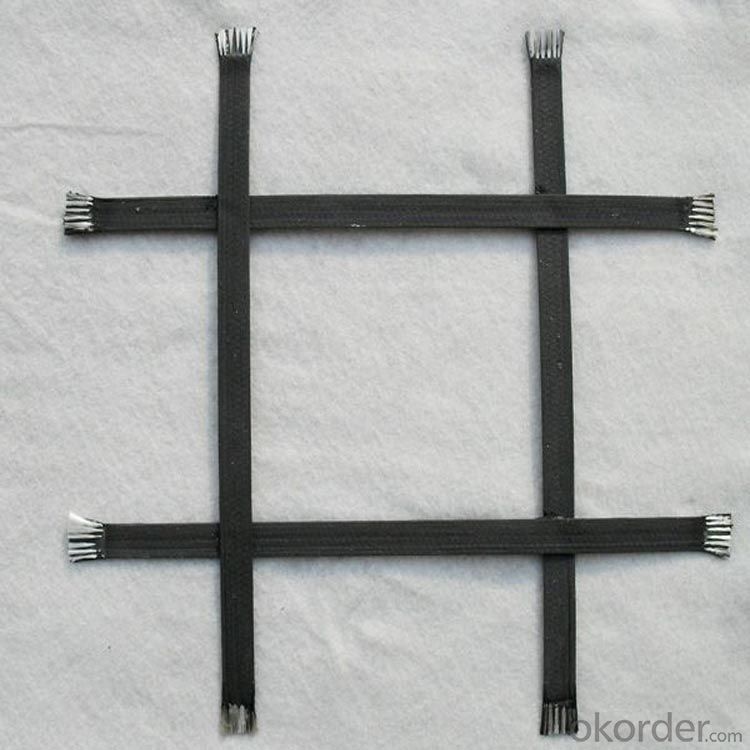

Introduction of Fiberglass Geogrid:

Fiberglass geogrid is based on fiberglass woven cloth coated with modified bitumen or PVC, it was developed to address the problem of pavement cracking on highways, roads and runways, driven by a need to reduce cost for infrastructure maintenance and repair.

It is characterized by high tensile strength in axial and lateral directions, low stretch rate, alkali-resistance, low temperature- resistance, as well as convenience in construction and low price. It can be used on pitch pavement to prevent cracks and prolong pavement service life. It also can be used as a basal reinforcement material for hillsides, reservoirs, harbors, ports, water channels, seawalls, etc.

Performance of Fiberglass Geogrid:

--- High strength, high modulus and low temperatures resistance.

Applications of Fiberglass Geogrid:

--- Reinforcement for road pavement

--- Reinforcement for railway basement

--- Reinforcement for Tunnel

--- Reinforcement for Slope

--- Reinforcement for embankment.

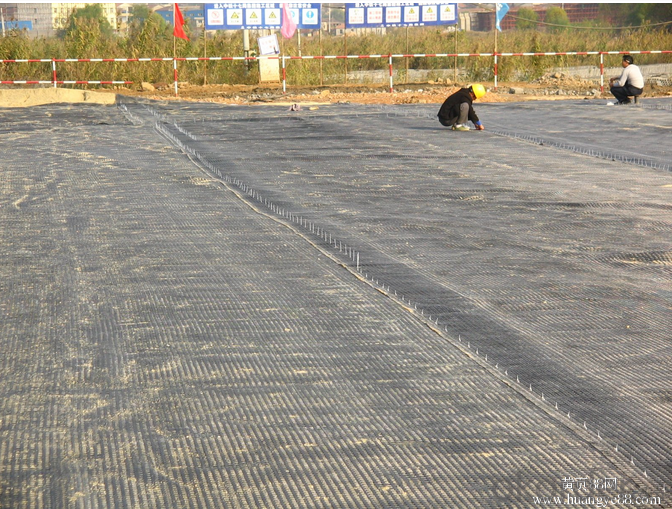

Introduction of PP Biaxial Geogrid:

Biaxial geogrid, made of high molecular polymer, is extruded into sheet and then punched into regular mesh pattern, and finally stretched in longitudinal and transverse directions.

Features of PP Biaxial Geogrid:

1. With high tensile strength in longitudinal and transversedirections

2.This structure can provide an chain system of more effective force bearing and spreading for the soil.

Application of PP Biaxial Geogrid:

Mainly applied in highway, railway, slope protecting projects etc.

1)strengthen land loading capacity and extend its service life.

2) convenient to construct ; reducing project cost and maintenance cost.

Introduction of PP/HDPE Uniaxial Geogrid:

Uniaxial geogrid, made of high molecular polymer, is extruded into sheet and then punched into regular mesh pattern, and finally stretched in the longitudinal direction.

Application of PP/HDPE Uniaxial Geogrid:

Mainly applied in highway, railway, slope protecting projects, retaining wall, dam etc.

1)strengthen land loading capacity and extend its service life.

2) convenient to construct ; reducing area , project cost and maintenance cost.

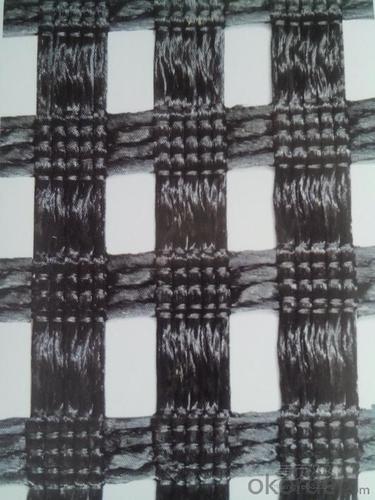

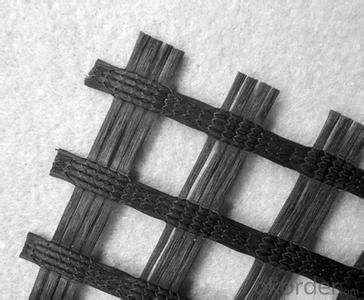

Introduction of Polyester Geogrid:

Polyester geogrid is a new kind of favorable earthwork base material to strength the road surface and roadbed, which composed of high strength polyester yarns coated with an inorganic sizing agent.

Features of Polyester Geogrid:

1) High tensile strength

2) High tear-resistant

3) Strong combination with gravel and soil

Application of Polyester Geogrid:

It mainly applied in strengthening soft ground of rail and road.

Sarah

- Q: How do gabions help in earthwork projects?

- Gabions help in earthwork projects by providing stability and erosion control. These wire mesh baskets filled with rocks or other materials act as retaining walls or barriers, preventing soil erosion, reducing water flow, and reinforcing embankments. They are easy to install and flexible, allowing for better drainage and preventing the accumulation of water behind the structure. Additionally, gabions can be used for slope protection, landscaping, and improving overall aesthetics in earthwork projects.

- Q: Why civil engineering materials are important

- From the perspective of resources and the environment and development prospects and other considerations and writing: such as the availability of materials, renewable, reusable, energy consumption, carbon sinks, etc., a lot of small, and need to find the relevant literature.

- Q: Can earthwork products be used in shoreline protection?

- Yes, earthwork products can be used in shoreline protection. These products, such as geotextiles, geogrids, and erosion control blankets, can help strengthen and stabilize shorelines, prevent erosion, and protect against water damage. These earthwork products are designed to withstand the forces of waves, tides, and currents, and are often used in coastal engineering projects to enhance shoreline resilience.

- Q: How do earthwork products contribute to land remediation and restoration?

- Earthwork products, such as soil, sand, and gravel, play a crucial role in land remediation and restoration. These products are used to fill and level contaminated or damaged land, creating a stable foundation for further remediation efforts. Additionally, earthwork products can be used to create berms, barriers, or containment structures that prevent the spread of pollutants and protect sensitive ecosystems. By providing the necessary materials for land regrading, erosion control, and vegetation establishment, earthwork products facilitate the rehabilitation of degraded land, ultimately restoring its functionality and ecological value.

- Q: How do geosynthetic meshes help in soil reinforcement for roadways?

- Geosynthetic meshes provide soil reinforcement for roadways by improving the stability and strength of the soil. These meshes are designed to distribute and transfer the load from the traffic evenly, reducing the stress on the soil and preventing its deformation or settlement. Additionally, geosynthetic meshes help in controlling soil erosion, enhancing drainage, and improving the overall performance and lifespan of the road.

- Q: Can earthwork products be used in mining and quarrying operations?

- Yes, earthwork products can be used in mining and quarrying operations. These products, such as geotextiles, geogrids, and geomembranes, are commonly used in these industries for various applications. They help in stabilization, erosion control, drainage, and containment, ensuring the safety and efficiency of mining and quarrying operations.

- Q: What is the purpose of using geocells in highway shoulder stabilization projects?

- The purpose of using geocells in highway shoulder stabilization projects is to provide reinforcement and support to the shoulder area, preventing erosion, soil displacement, and pavement cracking. Geocells act as a confinement system, effectively containing and reinforcing the underlying soil, increasing its load-bearing capacity and stability. This helps in improving the overall durability and longevity of the highway shoulder, reducing maintenance costs, and enhancing safety for motorists.

- Q: How are geosynthetic materials used in railway tunnel construction?

- Geosynthetic materials are used in railway tunnel construction to enhance the stability and durability of the tunnel structure. These materials, such as geotextiles, geogrids, and geomembranes, are installed to provide reinforcement, drainage, and erosion control. They help in preventing soil erosion, stabilizing slopes, and improving the overall safety and performance of the tunnel.

- Q: How do geosynthetic products contribute to soil erosion prevention in orchards?

- Geosynthetic products play a crucial role in preventing soil erosion in orchards. These specially designed materials, such as geotextiles, geogrids, and geocells, offer effective erosion control measures by stabilizing the soil, improving its water permeability, and providing reinforcement against potential erosion forces. They help retain soil particles in place, reduce runoff, and enhance water infiltration, thus ensuring the stability and preservation of orchard soils and preventing erosion damage.

- Q: Can earthwork products be used for beach erosion control?

- Yes, earthwork products can be used for beach erosion control. These products, such as sandbags and geotextile tubes, can be utilized to create barriers and reinforce beaches against erosion caused by waves and currents.

Send your message to us

Polyester Geogrid/ Fiberglass Geogrid/ PP Geogrid for Dam

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords