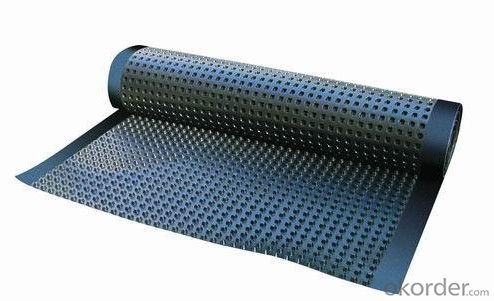

Drainage Composite Geonet Tri-dimension for Drainage

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

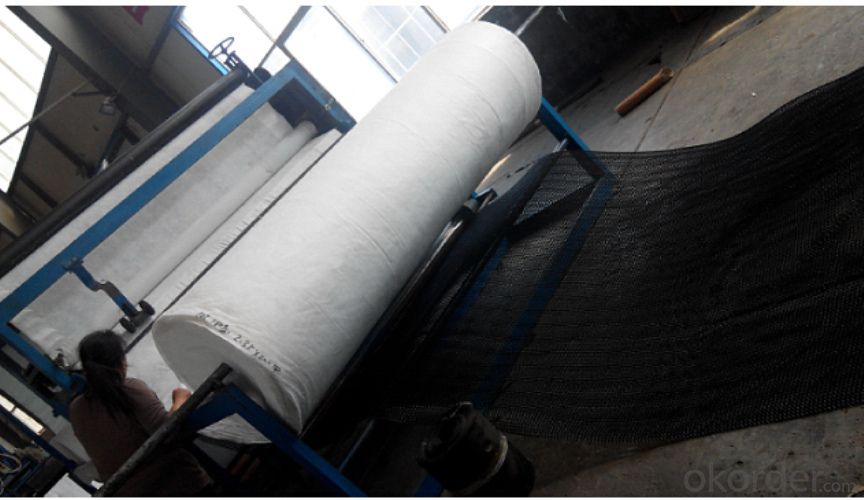

Drainage Composite Geonet

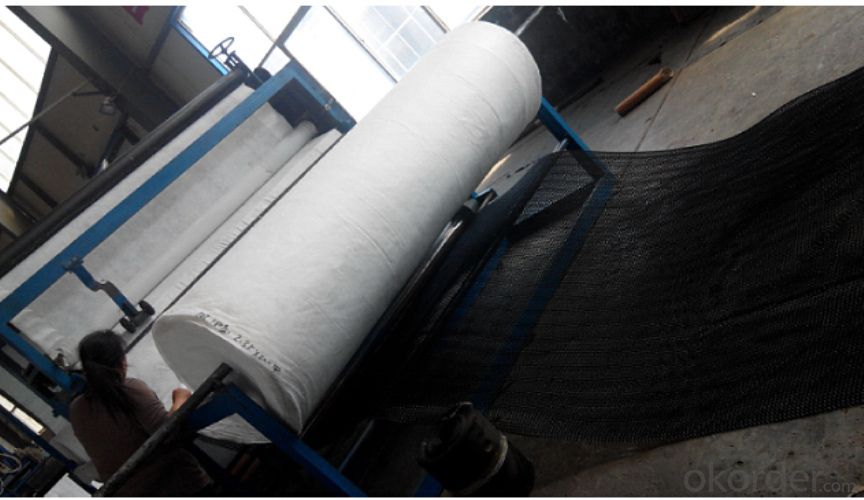

Introduction of Drainage Composite Geonet:

It's made of tri-dimension geonet coated geotextile on both sides. It has the property of geotextile (filtration) and geonet (drainage and protection), and has the complete function of "filtration--drainage-- protection".

Features of Drainage Composite Geonet:

- stronger drainage function and can bear high press load for a long time

- high tensile strength and shear strength

- keep stable water conductivity

- can bear compression load of more than 2000kpa

- larger anti-compression capacity than common geonet

Appications of Drainage Composite Geonet:

Widely used in landfill site drainage, highway roadbed and road surface drainage, railway system water drainage, tunnel drainage, underground structure drainage, retaining wall back drainage, garden and stadium drainage, etc.

-landfill drainage

-hignway roadbed

-railaway drainage

-tunnel drainage

-underground structure drainge

-retaining walls drainage

-garden and playground drainage

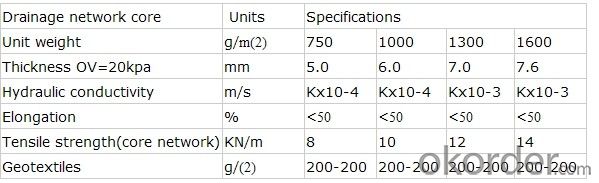

Drainage Composite Geonet technical specifications:

200/0.4/200, 200/7.0/200

Width:1m, 1.5, 2m, 2.5m

Length: 20m, 30m, 40m, 50m

Standard: GB/T19470-2004

FAQ:

1. Which payment do you accept?

For you convinience,our payment can be L/C,TT

2. Is free sample available?

We can supply free samples. You'll just need to pay for express cost.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world.

Photos:

- Q: How are geocells used for erosion control on riverbanks?

- Geocells are used for erosion control on riverbanks by creating a stable and permeable structure that reinforces the soil and prevents it from being washed away by the force of flowing water. The geocells are filled with soil, creating a strong foundation that supports vegetation growth and helps in retaining the riverbank, reducing erosion and promoting environmental stability.

- Q: Are earthwork products resistant to corrosion and rust?

- No, earthwork products are typically not resistant to corrosion and rust as they are made from materials like steel or iron, which are prone to corrosion when exposed to moisture and oxygen.

- Q: How are geocells used for load support in military installations?

- Geocells are used for load support in military installations by providing a stable and reinforced foundation for various structures and equipment. These three-dimensional honeycomb-like structures are filled with compacted soil or aggregate material, creating a strong platform that distributes weight evenly and prevents settling or shifting. This enables military installations to withstand heavy loads such as vehicles, aircraft, or temporary structures, ensuring operational efficiency and safety.

- Q: Civil Engineering Materials Laboratory electricity about how much watts

- This is hard to say, the laboratory equipment to ask the owners to know the electricity

- Q: What are the advantages of using geosynthetic clay liners for landfill lining?

- Geosynthetic clay liners (GCLs) offer several advantages for landfill lining. Firstly, GCLs provide an effective barrier against the leakage of contaminants from the landfill into the surrounding soil and groundwater. Their low hydraulic conductivity helps prevent the migration of pollutants, protecting the environment and human health. Additionally, GCLs are easy to install, reducing construction time and costs. They are lightweight, flexible, and can be easily transported and unrolled on-site. Moreover, GCLs have high tensile strength and puncture resistance, enhancing their durability and long-term performance. These liners also have a self-sealing ability, which allows them to self-heal in the event of minor punctures or cuts, maintaining their integrity over time. Overall, the use of geosynthetic clay liners in landfill lining ensures improved containment, cost-effectiveness, and environmental protection.

- Q: What are the different types of geosynthetic clay liners available?

- There are three main types of geosynthetic clay liners (GCLs) available: sodium bentonite GCLs, calcium bentonite GCLs, and mixtures of both. Sodium bentonite GCLs have a higher swelling capacity and are more commonly used in landfill and containment applications. Calcium bentonite GCLs have lower swelling capacity but are preferred in applications where high permeability is required. Mixed GCLs combine the characteristics of both sodium and calcium bentonite to provide a balance between swelling capacity and permeability.

- Q: How do geotextile tubes help in marine construction?

- Geotextile tubes are used in marine construction to provide effective erosion control and shoreline protection. These tubes are filled with sand or slurry and then placed in strategic locations to create barriers that prevent erosion and maintain stability. The geotextile fabric of the tubes allows water to pass through while retaining the fill material, ensuring that the construction remains intact even in high-energy marine environments. Additionally, these tubes can be easily installed, removed, and reused, making them a cost-effective and sustainable solution for marine construction projects.

- Q: Are there any earthwork products specifically designed for pipeline projects?

- Yes, there are earthwork products specifically designed for pipeline projects. These products include erosion control materials, geotextiles, and geomembranes that help stabilize the soil, prevent erosion, and provide protection to the pipeline during construction and operation. Additionally, specialized equipment such as pipeline padding machines and trench shoring systems are used to ensure the safety and efficiency of pipeline installation.

- Q: What is the purpose of using geocomposites in subsurface drainage systems?

- The purpose of using geocomposites in subsurface drainage systems is to enhance the performance and longevity of the system. Geocomposites provide a combination of various materials such as geotextiles and geonets, which work together to effectively filter, separate, and drain excess water from the soil. This helps to prevent soil erosion, maintain soil stability, and ensure proper drainage in areas where groundwater or surface water accumulation may pose a problem. Overall, geocomposites help to improve the efficiency and durability of subsurface drainage systems, leading to more effective water management and enhanced overall performance.

- Q: Are there any earthwork products specifically designed for airport construction?

- Yes, there are earthwork products specifically designed for airport construction. These products include geosynthetics such as geotextiles, geogrids, and geomembranes that are used to strengthen and stabilize the soil, prevent erosion, and provide drainage solutions. Additionally, specialized heavy machinery and equipment are also utilized for earthmoving, grading, and compacting purposes during airport construction projects.

Send your message to us

Drainage Composite Geonet Tri-dimension for Drainage

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords