Tower Crane TC7034 Construction Machiney and Equipment

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

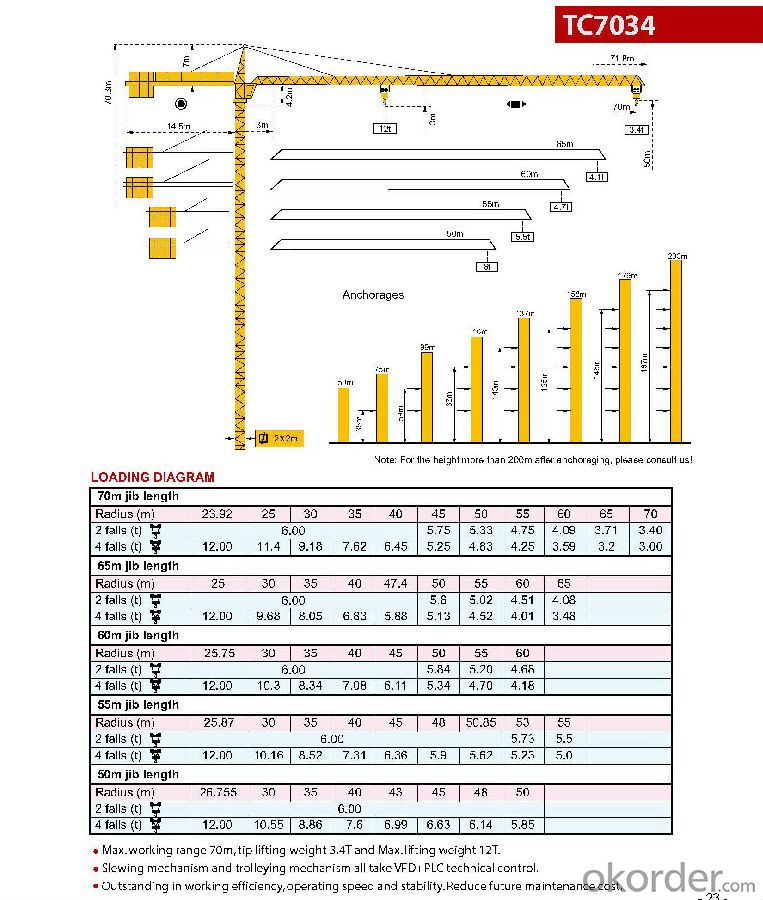

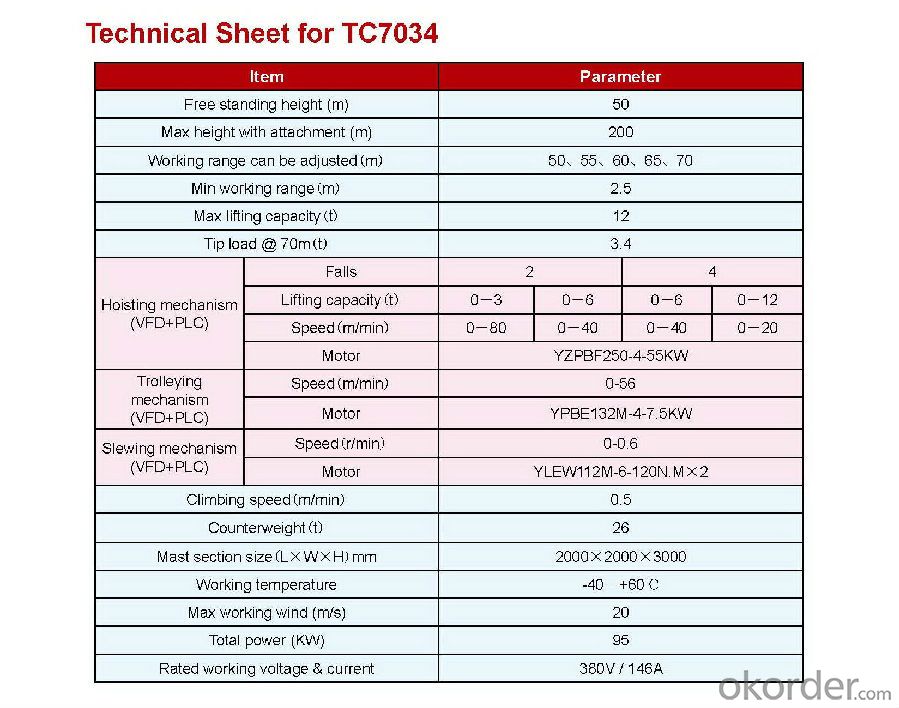

Tower crane is used to lift, lower and horizontally move materials in construction and other industry. It has large lifting capacity and lifting height, wide moving range, and can rotate. It basically consists of base foundation, mast, slewing unit, working jib, counter jib, counterweight, hook, and operating cabin.

Features:

1. It has high working speed, good speed-adjusting performance, steady operation and high efficiency. Three-speed motor and mono-speed ratio decelerator are applied in the lifting struction, which enables heavy load low speed and light load high speed.

2. The range-change structure drives the dolly to change range on the horizontal arm, with good positioning performance. Planet gear decelerator is applied in the circumgyrating structure, together with moment-limiting hydraulic coupler, which can relize high load capacity, steady starting and reliable operation.

3. The crane has complete set of safety devices, which can guarantee the safe and high efficienct operation of the equipment. The machine is equipped with lifting height limiter, dolly range-change limiter, moment limiter, weight limiter, circumgyrating limiter, etc.

4. The operator's room is set independently on one side, with good vision field. It creates a good working environment for the operator.

5. Provide stepless speed regulation. Outstanding in working efficiency, operating stability and reliability,

6. This Tower Crane' s height can accordign to the actual height of the building and at the same time unchange the lifting capacity.

7. LVF: Frequency control, variable speed, smoothness and high stability, no striking.

The advantages of our company's products

1.Thirteen years of experience in supplying new self-erecting tower crane with Huiyou Brand.

2. Export to more than 20 countries with CE/ISO/GOST Certificates.

3. Stationary/Travelling, external/ internal climbing tower crane

4. Impeller blasting/rust protection paint

5. Advanced painting process

6. Potain masts designed with dismountable panels, making teansport easier and cheaper.

7. New designed mast, can be used to Internal and external climbing tower crane

8. Famous brand mechanism system, Schneider Electronic control system, jiangte and jiuhe motor

9. Engineers available to service machinery overseas.

10. For warranty, it is 12 months from the B/L date.What's more, some free easy worn spare parts are provided together with the crane.

Specifications:

- Q: My grandma has just gotten cancer and I want to send her a paper crane in her get well card. However, is it bad luck to send just one, do you have to send 1,000? I would like to send 1,000 but i don't have the time, experience with origami, or enough room in the envelope, and i only have till tomorrow.

- No okorder /

- Q: if anyone can inform me about any of these styles in debt even if just one id greatly appreciat itbest ansewer will be hard here cause i will b thankful for all who give a sincere ansewer

- To be honest I wish I knew more, but here's what I do know of Wah Lum. They have great hand trapping techniques that can be utilized while standing. A perfect compliment for close quarter combat. They come in real handy in bridging the gap. They ( like Wing Chun ) have sensitivity drills used for heightening your awareness of your opponents subtle movements. If you're a boxer,wrestler,or basically any other Martial Art practitioner. This is a good Art to at least be acquainted with.

- Q: The cantilever part has to stay at least 6-12 inches off the ground.

- This Site Might Help You. RE: What are some ideas to build a crane out of Popsicle sticks? The cantilever part has to stay at least 6-12 inches off the ground.

- Q: What is the rental price of a tower crane? General site rental more, but also buy more? Ask the industry for an answer?

- Is the site of the tower crane is not, the crane company specializes in the construction site is rented, the price range depends on the length of your period, due to demolition of the problem, I am not a professional, but I am working at the site, only know so much

- Q: How much should the verticality of a tower crane be controlled? Thank you

- No, the wind speed is not more than 3m/s, the independent state tower (or attached state highest attachment point above the tower axis) lateral verticality tolerance is 4/1000, the highest tower axis perpendicularity allowed attachment line below the point of difference is 2/1000.

- Q: Calculate how much power the crane has?

- the crane ?? The crane is not defined.

- Q: i have a female Doberman 4months old. running here n there, we spend time with her morning and night, four days per week we go to a big ground and walking with her more than a hour per day, is it adequate? she seems very happy and waiting for us on every evening (me and my wife) also i need an advice on her crane? i have put her in some what big (5ft 4ft) place beside my front door, not fully covered but well sheltered by the house roof/. is it ok to have an open crane like that?

- I have no idea what an open crane is? Do you mean you leave her outside all day? If so, the answer is no. Dobermans don't have the right type of coat to be left outside all day even with shelter.

- Q: The crane was commissioned in the plant some 15 yrs back. The cranes is being used for lifting hot metal (iron) from furnace to Pig casting machine since commissioning. Regular maintenance is being done on the same.

- no you have to asses the related struturals.

- Q: Can Ichabod Crane defeat the Headless Undocumented Worker before he prunes someone's bushes into hedges?

- It's people like you who are the reason the governor of our state had to declare a STATE OF EMERGENCY to get federal help to stop these people from coming here. You do not understand the problem because you ARE the problem.

- Q: What are the differences between the tower crane and the lift?

- they are nothing alike

Send your message to us

Tower Crane TC7034 Construction Machiney and Equipment

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords