Tower Crane 8 Ton Max Capacity TC5516 QTZ100

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Detail of Tower Crane

Feature:Tower Crane

Condition:New

Model Number:TC5516(QTZ100)

Place of Origin: China (Mainland)

Brand Name: CMAX

Certification: ISO,CE

Warranty: 1 Year

Application:Building,Construction,Industrial

Main Features of Tower Crane

1) This kind of crane adopts standard section hydraulic lifting and connecting.The max. height can reach 180m with wall tie ins.

2) It has high working speed, good speed-adjusting performance, steady operation and high efficiency. Three-speed motor and mono-speed ratio decelerator are applied in the lifting struction, which enables heavy load low speed and light load high speed.

3)The range-change structure drives the trolley moving on the horizontal crang jib, with good positioning performance. Planet gear decelerator is applied in the circumgyrating structure, together with moment-limiting hydraulic coupler, which can relize high load capacity, steady starting and reliable operation.

4) The crane has complete set of safety devices, which can guarantee the safe and high efficienct operation. The crane is equipped with lifting height limiter, trolley ranging limiter, moment limiter, weight limiter etc..

5)The cranehas scientific layout and handsome appearance. The drivers cab is set independently on one side, with good vision field. It creates a good working environment for the operator.

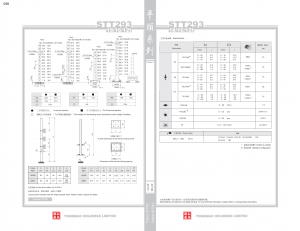

Specification of Tower Crane

Technical Sheet for TC5516

Free standing height (m) | 44 | ||||

Max height with attachment (m) | 150(200) | ||||

Working range can be adjusted(m) | 45、50、55 | ||||

Min working range(m) | 2.5 | ||||

Max lifting capacity(t) | 8 | ||||

Tip load @ 55m(t) | 1.6 | ||||

Hoist mechanism | Falls | 2 | 4 | ||

Lifting capacity(t) | 0-2 | 0-4 | 0-4 | 0-8 | |

Speed(m/min) | 0-80 | 0-40 | 0-40 | 0-20 | |

Motor | YZRWFc250M-4/8 30/30KW | ||||

Trolleying mechanism | Speed(m/min) | 12/27/53 | |||

Motor | |||||

Slewing mechanism | Speed(r/min) | 0~0.6 | |||

Motor | YZR132M2-6-3.7KW×2 | ||||

Climbing speed(m/min) | 0.5 | ||||

Counterweight(t) | 17.6 | ||||

Mast section size(L×W×H)m | 1.6×1.6×3.0 | ||||

Working temperature | -40-+60℃ | ||||

Total power (KW) | 42 | ||||

Power supply requirement (KVA) | 190KVA for generator | ||||

Cable type ( within 40 meters from site power source to lower electric box of tower crane ) | |||||

Startup voltage & current | 380V×95%=361V 179A | ||||

Rated working voltage & current | 380V 128A | ||||

Loading diagram:

55m jib length:

R m | 3.1—13.5 | 17 | 22 | 27 | 33 | 37 | 45 | 47 | 50 | 52 | 55 | |

a=2 | 4t—24.65m | 3.61 | 3 | 2.61 | 2.38 | 1.95 | 1.8 | 1.72 | 1.6 | |||

a=4 | 8t | 6.2 | 4.62 | 3.41 | 3 | 2.61 | 2.38 | 1.95 | 1.8 | 1.72 | 1.6 | |

50m jib length:

R m | 2.5—15.17 | 19.65 | 22 | 25 | 27.4 | 33 | 38.5 | 42 | 47 | 50 |

a=2 | 4t---27.6m | 3.22 | 3 | 2.71 | 2.37 | 2.2 | ||||

a=4 | 8t | 6.2 | 5.53 | 4.76 | 4 | 3.22 | 3 | 2.71 | 2.37 | 2.2 |

45m jib length:

R m | 2.5—15.17 | 22 | 25 | 27.4 | 29.8 | 33 | 38.5 | 40 | 42 | 45 |

a=2 | 4t | 3.65 | 3.22 | 3 | 2.87 | 2.71 | 2.5 | |||

a=4 | 8t---15.17m | 5.53 | 4.76 | 4.2 | 3.65 | 3.22 | 3 | 2.87 | 2.71 | 2.5 |

Images of Tower Crane

FAQ about Tower Crane

Q: What serice you could provide?

A: Providing timely delivery, standby engineers are ready to slove any of your problem

Providing all-embraced warranty of products quality, worksite installation guidance

Providing ample spare parts and training of operation and maintenance

Engineers have more than 20 years' experience in tower crane, ready to solve any of your problems.

Q: What kind of steel used for tower crane ?

A: Normally, as for the main force bearing steel structure, Q345B is adopted; as for the assistance force bearing steel structure Q235B is adopted. All of the raw material is outsourced from qualified steel factory in China.

Q: What about our tower crane warranty?

A: Usually there is one-year quality warranty including main electronic parts (not including consumable parts). There are consumable spare parts together with whole machine and normally they are enough for one year.

Q: What is 3 main mechanism of the tower crane ?

A: there are trolleying mechanism/ slewing mechanism/ hoisting mechanism.

Q: Can you equip with light on tower crane jib, monitor, remote control and anemometer?

A: Sure. All of these could be provided with extra cost upon the clients' requirements. But according to general practice, remote control is not suggested because most of the operator feedback operation in the cabin will provide a wide working view.

- Q: Tower cranes sometimes have very long booms, but seem to usually have fixed counter-weights at fixed positions behind the cab. Why doesn't it flip backwards when there is no load, or flip forwards when a load is way at the far outward end of the boom? It seems to be a very large range of moment arms given that the counter-weight has a fixed one.

- I think the counter weights are connected to a pully system that directly interacts with the boom and hook movement. This way it can put more or less pull on the weights according to the amount of weight or position of the weight on the crane.

- Q: was he a realist or naturalist

- Stephen Crane was a naturalist a lot like Jack London. His main themes were man vs. nature and man vs. himself in which nature is an abstract, omnipotent force that does not (and really cannot) care what becomes of the individual. In Crane's writings, man is often faced with strengths and weaknesses within himself when confronted by extremes of uncaring Nature (see the short story The Open Boat).

- Q: On Batman Begins what is Dr. Crane's full name?

- who cares are u bout 6 or something???

- Q: My best friend is going to live in Japan for about a year soon, and I want to send him a birthday present while he's there. A lot of the places I've looked say it's common to make 1000 cranes for people as a wedding present, or in preparation for your own wedding so I'm not sure this is an appropriate gift -___- Also, I have no idea how I would ship them to him...

- A 1000 cranes set is a lovely thought would be a wonderful present. But you have one problem. How many boxes will it take to ship 1000 origami cranes to Japan? How much will it cost? Remember, airmail is very expensive, USPS doesn't do overseas surface mail anymore. Mailing parcels to Japan with DHL/UPS would cost you at least $80 for 20 pounds or less. You would do better to send your friend cash by wire transfer. Furthermore, since your friend will be in Japan for 12 months, I would guess his living quarters are not spacious. The average home is only 1000 sq feet in size. Apartments can be as tiny as 100 sq.ft. Where will he put 1000 cranes? He will have it for a few months before he has to pack to return home. What will he do then? Toss the cranes or ship them home? I believe he would prefer to have the wire transfer. Cost of living in Japan is high. Cash is going to be so appreciated even if 1000 cranes gift is a sweet sentimentality. Check the sites referenced for cost of shipping.

- Q: In the private training session, Katniss Everdeen creates a noose, hangs a practice dummy, and uses the paint to write: Seneca Crane. I know this name is mentioned earlier in the book, but I don't remember who Seneca Crane is... Remind me, please?

- Seneca Crane is the previous Gamemaker who decided to allow Peeta and Katniss to live after the berry incident. The Capitol killed her and replaced her for that act of mercy. That's why Katniss hung her; she was rebelling against the Capitol and implying that they murdered Seneca Crane.

- Q: We would like some ideas from folks who have the cranes coming to their bird feeders. What foods are they attracted to?

- They like shallow swampy areas with medium to tall grasses

- Q: Do large semi-submersible crane vessels such as the SSCV Thialf propel themselves to work sites or are they carried on heavy-lift ships. I understand they have propulsion systems but the just seem so bulky, inefficient, and slow to move across oceans on their own.

- Very large capacity crane vessels have propulsion machinery for manoeuvring when on station. The most modern designs of semi-submersible vessel use them to achieve 'dynamic positioning'. Older designs used the propulsion systems to assist when deploying the anchors in the correct pattern. The vessels are towed by tugs when making deep sea passages. First generation crane vessels had much smaller lifting capacities and were either constructed on conventional hulls or were converted from existing ships. These types were capable of making ocean passages using their own propelling machinery.

- Q: sun/rising/etcBQ: how often are your winnings

- I love this question. My uncle is pretty good at it. I haven't tried because primarily most of these machines I've come across have mostly crap or the crap is pancaked on top of all what I consider the goodies--like a baby pink Domo! Y'know, maybe I should try it sooner. OOooh, a moose!

- Q: My understanding is that under Crane doctrine the tax basis of the property to begin with is Equity Invested + Financing (recourse or nonrecourse doesn't matter). i.e. 20K down + 80K purchase money mortgage = 100K. What if the property is appraised for only 80K right before purchase but purchaser paid 100K? Is the tax basis 80K or 100K.In other words, is the tax basis the actual assessed value of the property or is the tax basis the total investment?Thanks,Ben

- Your understanding of Crane is correct. For purposes of calculating the gain on sale, the basis would be $100k. What Crane really said was that the net proceeds would have to include any assumed debt, in addition to any cash received -- basically that you had to include the debt on both ends of the transaction if my reading is correct. (That jives with the example in Commissioner v Tufts et al, 81-1356 so I think we're correct on that.) Where basis gets interesting is when you are calculating depreciation. At least when you convert a residential property to business use -- i.e. a rental -- you use the LESSER of the cost basis (Crane) or the FMV on the date that the property is placed in business(rental) service. In your example, the depreciable basis would be $80k since that was the lower. For calculating the gain on sale, the cost basis would still be $100k (adjusted down for any depreciation allowed or allowable while in business use of course).

- Q: I am writing a story for school about working in Dubai as a crane driver but I need to know what the purpose of a Crane driver is, how much they get payed and stuff like that. And if you could tell me how a crane driver can get admission in the first place, it would be really great. Thanx. And btw, this story is for Geography.Thank you. :)

- i am not a crane driver myself , but into this field of construction . get a licence as driver from authority just as a car driver. know how to drive the crane ad a driver know how to operate a crane as a operator. know the performance of the crane and its limits. the salary can vary depending on the type of crane and its special features. but not in the high end grade for sure unless its a very specialised crane operation. u can ask any thing more .

Send your message to us

Tower Crane 8 Ton Max Capacity TC5516 QTZ100

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords