Torched Sbs/app Waterproofing Bitumen Membrane

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 44 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description

SBS modified bitumen waterproof membranes use high quality needle punched polyester mat or fiberglass compound mat as the base reinforcement. And use SBS modified bitumen as the dip-coat material. The SBS modified bitumen waterproof membrane are widely used for roof waterproof projects.

Specifications

1. Width: 125px-1m or as customized

2. Length: 3m/5m/10m/15m/20m or as customized

3. Thickness: 2mm/3mm/4mm/5mm

4. Surface: PE film, Colorful Sand, Mineral Granules or Aluminium foil

Technical Parameters

No. | Item | Index | |||||

I | II | ||||||

PY | G | PY | G | PYG | |||

1 | Solvend content(g/m²)≥ | 3mm | 2100 | - | |||

4mm | 2900 | - | |||||

5mm | 3500 | ||||||

Experiment phenomena | - | Carrier non-ignitable | - | Carrier non-ignitable | - | ||

2 | Heat risistance | °c | 90 | 105 | |||

≤mm | 2 | ||||||

Experiment phenomena | Non flow,dippage | ||||||

3 | Cold bending/°c | -20 | -25 | ||||

No crack | |||||||

4 | Waterproof 30min | 0.3MPa | 0.2MPa | 0.3MPa | |||

5 | Tensile strength | Maximum peak tensile(N/50mm)≥ | 500 | 350 | 800 | 500 | 900 |

Inferior peak tensile (N/50mm)≥ | - | - | - | - | 800 | ||

Experiment phenomena | In stretching process,the test specimen has no asphalt cracks or separate with the carrier | ||||||

6 | Elongation | Maximum peak elongation | 30 | - | 40 | - | - |

Inferior peak elongation | - | - | 15 | ||||

Product Feature

1. SBS modified bitumen waterproof membrane has good watertightness.

2. SBS modified bitumen waterproof membrane is high strength of extension, good ductility

3. SBS modified bitumen waterproof membrane is special used for low temperature.

4. SBS modified bitumen waterproof membrane is easy construction, can be constructed all of the year by the way of hot melt.

Application

1.Make sure the roof deck is smooth,clean and dry(Moisture<9%),then apply the surface of roof deck with a kind bitumen paint till dry.

2. There are two methods in application:

One way is by heating and melting method---Heat the membrane and roof deck surface by heating and melting method to be nearly melted(not flowing),then install the membrane fully bonded to the roof deck with overlaps of 5-250px.

The other way is by cold adhesive method---Pour the cold adhesive on the roof deck then roll the membrane to install it to be fully sticked to roof deck.

By heating and melting method and by cold adhesive can be used in alternation as requested.

3.After application,, a full serious inspection is required,that’s to make sure no air bubble,,no fold,,no falling away etc. and guarantee the waterproof life.

Requirements for construction

1.The base should be dry and clean. Do not work in the rainy or snowy day.

2.Do not work under heavy wind(above 5 grade)

3.Unsuitable for construction below 5°C

4.If it is rain or snow in the process of construction, protective measure to the laid membrane is must.

5.All the workers should put on special uniforms to keep safe when installing. There should be equipments for fire controls.

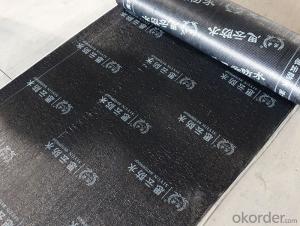

product show

FAQ

Q: What's the delivery time ?

A: 3-5 days for 1-600 rolls, 10-15 days for container.

Q: What's the payment terms ?

A: TT/LC

Q: How do you make replacement with quality problems ?

A: New replacement will be packed into your next order or send to you directly after receive video or photo about quality problems.

- Q: What is the difference between a liquid and sheet-type waterproofing membrane?

- A liquid waterproofing membrane is a type of coating that is applied in liquid form and then dries to form a protective layer. It is typically applied using a brush, roller, or spray. On the other hand, a sheet-type waterproofing membrane is a pre-manufactured material that is typically made of rubber, PVC, or bitumen. It comes in large rolls or sheets and is usually installed by overlapping the sheets and adhering them to the surface using adhesives or heat. In terms of installation, liquid waterproofing membranes are generally easier to apply as they can be easily molded and shaped to fit various surfaces and contours. They can also be applied to both horizontal and vertical surfaces without the need for seams or joints. Sheet-type membranes, on the other hand, require careful measurements and cutting to fit the surface properly. They also require more labor and time to install due to the need for overlapping and sealing the joints. In terms of flexibility, liquid membranes tend to have better flexibility as they can conform to irregular surfaces and movements without cracking or tearing. Sheet-type membranes, although flexible to some extent, may not be able to adapt as well to surface movements or changes in temperature. Another difference is in terms of durability and lifespan. Sheet-type membranes are typically thicker and more robust, providing a longer lifespan and better resistance to punctures and mechanical damage. Liquid membranes, although they can provide effective waterproofing, may not be as durable or long-lasting, especially in high-traffic areas or areas prone to damage. In terms of cost, liquid waterproofing membranes are generally more cost-effective compared to sheet-type membranes. They require less labor and materials for installation, making them a more budget-friendly option. However, it's important to consider the specific requirements and conditions of the project to determine the most suitable type of waterproofing membrane. Overall, the choice between a liquid and sheet-type waterproofing membrane depends on various factors such as the nature of the project, the surface conditions, the level of flexibility and durability required, and the budget constraints.

- Q: Can a waterproofing membrane be used in conjunction with insulation materials?

- Using both insulation materials and a waterproofing membrane together is often recommended in order to protect buildings from moisture and improve energy efficiency. The waterproofing membrane acts as a barrier against water infiltration, while the insulation materials help regulate temperature and minimize heat loss or gain. By combining these components, the building envelope can effectively shield against water damage and maintain a comfortable indoor environment. Proper installation and compatibility between the waterproofing membrane and insulation materials are crucial for achieving optimal performance and long-lasting results.

- Q: Are waterproofing membranes suitable for commercial applications?

- Yes, waterproofing membranes are suitable for commercial applications. They are designed to provide a protective barrier against water infiltration, making them ideal for use in commercial buildings such as offices, retail spaces, and warehouses. Waterproofing membranes are durable, long-lasting, and can be applied to various types of surfaces, ensuring the integrity and longevity of commercial structures.

- Q: Can a waterproofing membrane be used on zinc surfaces?

- Certainly! Zinc surfaces can indeed benefit from the application of a waterproofing membrane. Zinc is widely used for its durability and resistance to corrosion, making it a popular choice for various purposes such as roofing and cladding. By adding a waterproofing membrane to zinc surfaces, an extra layer of protection against water intrusion and moisture damage can be achieved. This not only helps prevent leaks, but also extends the lifespan of the zinc surface and preserves its overall integrity. However, it is crucial to ensure that the chosen waterproofing membrane is compatible with zinc and specifically designed for such applications. To determine the most suitable waterproofing solution for zinc surfaces, it is advisable to seek professional advice or consult with the manufacturer.

- Q: Can a waterproofing membrane be applied on top of insulation materials?

- Applying a waterproofing membrane on top of insulation materials is possible. In fact, it is often advisable to install a waterproofing membrane over insulation materials to provide an extra layer of safeguard against moisture infiltration. This is particularly crucial in areas vulnerable to water damage, such as basements or places prone to heavy rainfall. The waterproofing membrane helps prevent water from seeping into the insulation, which could cause harm or reduce its efficiency. Moreover, the membrane acts as a barrier, inhibiting water vapor from penetrating the insulation and potentially causing condensation or mold growth. However, it is vital to ensure proper installation of the insulation materials and the presence of any required air gaps or drainage systems to avoid water from getting trapped between the membrane and the insulation.

- Q: Can a waterproofing membrane be used for both interior and exterior applications?

- Yes, a waterproofing membrane can be used for both interior and exterior applications.

- Q: Are waterproofing membranes suitable for underground parking garages?

- Yes, waterproofing membranes are suitable for underground parking garages. They provide an effective barrier against water infiltration, preventing damage to the structure and protecting against potential leaks and moisture-related issues. Waterproofing membranes are designed to withstand the high water pressure typically associated with underground environments, making them an ideal solution for ensuring the longevity and durability of underground parking garages.

- Q: What is the material on the insulation layer on the waterproofing membrane?

- 2, waterproof layer on the other construction layer construction, it is possible to pierce the waterproof layer, the appropriate protection Is necessary, the isolation layer can also play a protective role.

- Q: Can a waterproofing membrane be used in areas with heavy rainfall or high water tables?

- A waterproofing membrane is suitable for use in regions experiencing heavy rainfall or having high water tables. It is specifically crafted to prevent the infiltration of water and effectively shield structures from water damage. These membranes are constructed using materials like bitumen, rubber, or polyurethane, which serve as a barrier against moisture. They are installed on the exterior side of walls, roofs, or foundations to establish a tight seal against water. To cope with the constant exposure to water in areas with heavy rainfall or high water tables, it is crucial to employ a top-notch and long-lasting waterproofing membrane. Moreover, it is essential to ensure the effectiveness of the waterproofing system through proper installation techniques and regular maintenance.

- Q: How does a waterproofing membrane handle moisture from the ground?

- To effectively manage moisture from the ground, a waterproofing membrane is designed to create a barrier that stops water infiltration. It is typically constructed using impermeable materials like rubber, bitumen, or modified asphalt. When correctly implemented, the membrane forms a continuous, watertight layer that prevents water from seeping through the foundation or walls. Typically, the membrane is placed on the exterior side of a building's foundation, where it serves as a protective shield against groundwater. It is applied directly onto the concrete or masonry surface, forming a seamless and durable waterproofing layer. To ensure its long-term durability, the membrane is then covered with a protective layer, such as soil or backfill. In addition to being impermeable, a waterproofing membrane also incorporates features that enable it to handle moisture effectively. For example, it may include built-in channels or dimples that facilitate the drainage of water away from the foundation, preventing the accumulation of hydrostatic pressure. Some membranes even possess self-healing properties, allowing them to seal minor punctures or cracks that may develop over time. Overall, a properly installed waterproofing membrane serves as a dependable barrier against ground moisture. It safeguards the structure from water damage, prevents the growth of mold and mildew, and maintains a dry and healthy indoor environment. However, it is crucial to ensure correct installation by adhering to the manufacturer's guidelines and seeking assistance from experienced professionals to guarantee its effectiveness.

Send your message to us

Torched Sbs/app Waterproofing Bitumen Membrane

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 44 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords